Choosing the Right Material for Your Bonded Seal Applications

Choosing the Right Material for Your Bonded Seal Applications

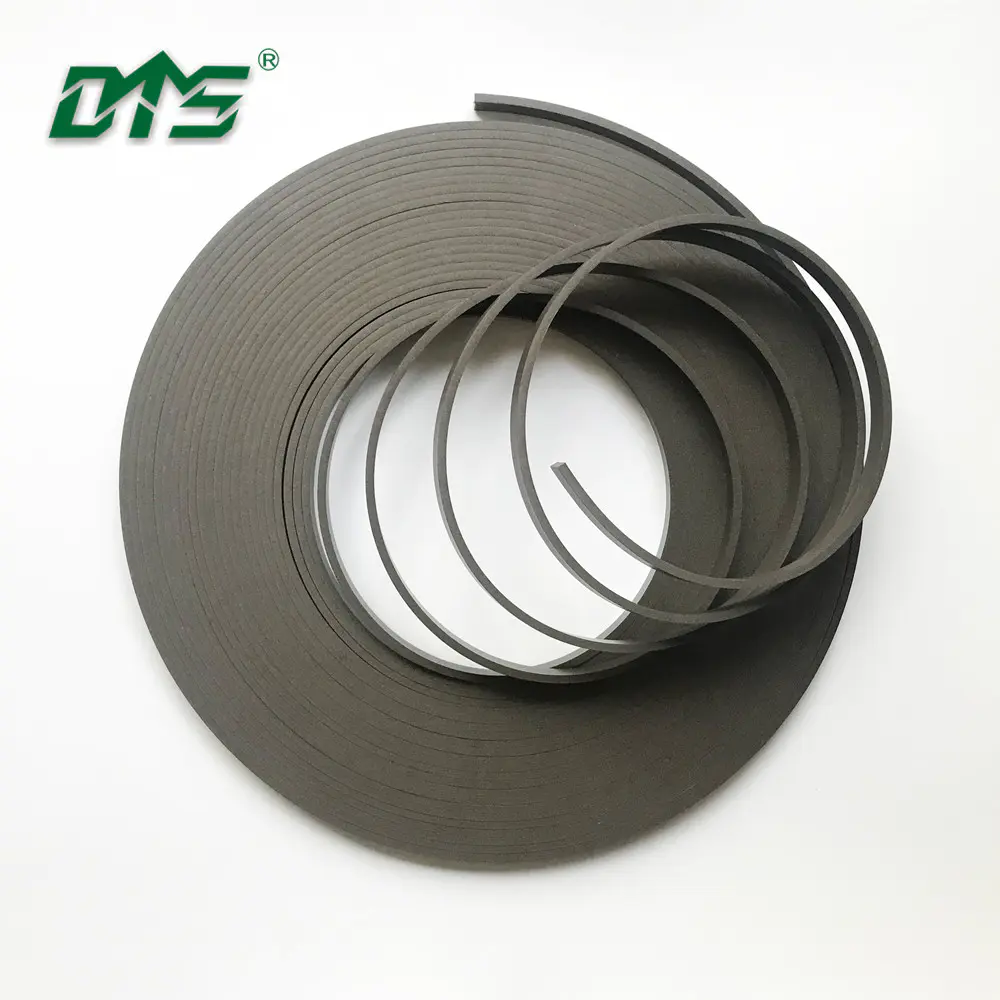

Bonded seals are used in a variety of industrial applications for sealing purposes. They are a type of mechanical seal that combines a metal washer and an elastomer O-ring in one unit. The metal washer provides a rigid support for the O-ring and ensures that the O-ring is properly compressed and sealed.

Bonded seals are used in applications where the connection between two surfaces needs to be leak-proof. They are commonly used in hydraulic systems, automotive engines, pipe systems, and industrial machinery. These seals are ideal for sealing applications where high-pressure and strong vibrations are expected.

Choosing the right material for your bonded seal applications is critical to ensuring that the seal functions properly and efficiently. Different materials perform better in different environments and applications. Here are some factors to consider when selecting a bonded seal material.

1. Operating Temperature Range

The operating temperature range is one of the most important factors to consider when selecting a bonded seal material. Different materials have different temperature ranges they can operate in. For instance, some materials can withstand high temperatures, while others cannot. Some materials may also become brittle or experience other changes in properties when exposed to extreme temperatures.

When selecting a bonded seal material, it is critical to consider the temperatures the seal will be exposed to during operation. This will help you select a material that can withstand the temperatures without undergoing significant changes in its properties.

2. Chemical Compatibility

The chemical compatibility of the material is another important factor to consider when selecting a bonded seal material. This refers to the ability of the material to resist chemical attacks from the environment or fluids it will be exposed to during operation. Different materials have different chemical compatibilities.

When selecting a bonded seal material, it is critical to consider the chemicals the material will be exposed to during operation. This will help you select a material that can resist chemical attacks and maintain its integrity during operation.

3. Pressure Rating

The pressure rating is another critical factor to consider when selecting a bonded seal material. Different materials have different pressure ratings. Some materials can withstand high pressures, while others cannot. It is important to select a material that can withstand the expected pressure during operation without experiencing failure.

4. Wear Resistance

The wear resistance of the material is another critical factor to consider when selecting a bonded seal material. Some materials are more wear-resistant than others. A material that is wear-resistant can withstand friction and wear during operation without undergoing significant changes in its properties.

When selecting a bonded seal material, it is critical to consider the amount of wear the material will be exposed to during operation. This will help you select a material that is wear-resistant and can maintain its integrity during operation.

5. Cost

The cost of the material is also an important factor to consider when selecting a bonded seal material. Different materials have different costs. It is important to select a material that is cost-effective while still meeting the requirements of the application.

There are several materials used for bonded seals, including Nitrile, Fluorocarbon, Silicone, and Ethylene Propylene. Here is a breakdown of their properties to help you select the right material for your bonded seal application.

1. Nitrile

Nitrile is a synthetic rubber material that is widely used for bonded seals. It has excellent oil resistance and performs well in temperatures ranging from -35°C to 120°C. Nitrile is also relatively cost-effective and is suitable for most hydraulic applications.

2. Fluorocarbon

Fluorocarbon, commonly known as Viton, is a synthetic rubber material that has excellent chemical and heat resistance. It can withstand temperatures ranging from -20°C to 200°C and has excellent resistance to chemicals, fuels, and oils. Fluorocarbon is ideal for applications where there is contact with aggressive chemicals and fuels.

3. Silicone

Silicone is a synthetic rubber material that has excellent heat resistance and performs well in temperatures ranging from -60°C to 200°C. It has excellent resistance to ozone, UV, and weather conditions. Silicone is ideal for low-pressure applications in which there is no contact with fuels, oils, or aggressive chemicals.

4. Ethylene Propylene

Ethylene propylene is a synthetic rubber material that has excellent heat resistance and performs well in temperatures ranging from -40°C to 150°C. It has excellent resistance to ozone, UV, and weather conditions. Ethylene propylene is ideal for sealing applications in which there is contact with steam, water, or other fluids.

In conclusion, selecting the right material for your bonded seals application is vital for ensuring an efficient and leak-proof seal. Consider the operating temperature range, chemical compatibility, pressure rating, wear resistance, and cost when selecting the material. Different materials have different properties, and selecting the right material can enhance the performance and longevity of your seals.