Enhancing Equipment Longevity with High-Performance Wiper Seals

Enhancing Equipment Longevity with High-Performance Wiper Seals

Introduction

Wiper seals play a crucial role in ensuring the longevity and optimal performance of various types of equipment. These seals are responsible for keeping out contaminants, preventing leakage, and maintaining the smooth operation of crucial components. By using high-performance wiper seals, businesses can significantly enhance the durability and reliability of their equipment, saving on maintenance costs and downtime in the long run.

The Importance of Wiper Seals in Equipment

1. Preventing Contamination

One of the primary functions of wiper seals is to prevent contaminants from entering critical equipment components. Machinery operating in harsh environments, such as construction or mining equipment, is particularly susceptible to dust, dirt, and debris. When these particles infiltrate sensitive parts, they can cause the equipment to malfunction, resulting in reduced efficiency and costly repairs. High-performance wiper seals ensure that foreign substances are kept at bay, extending the lifespan of the equipment.

2. Sealing Against Leakage

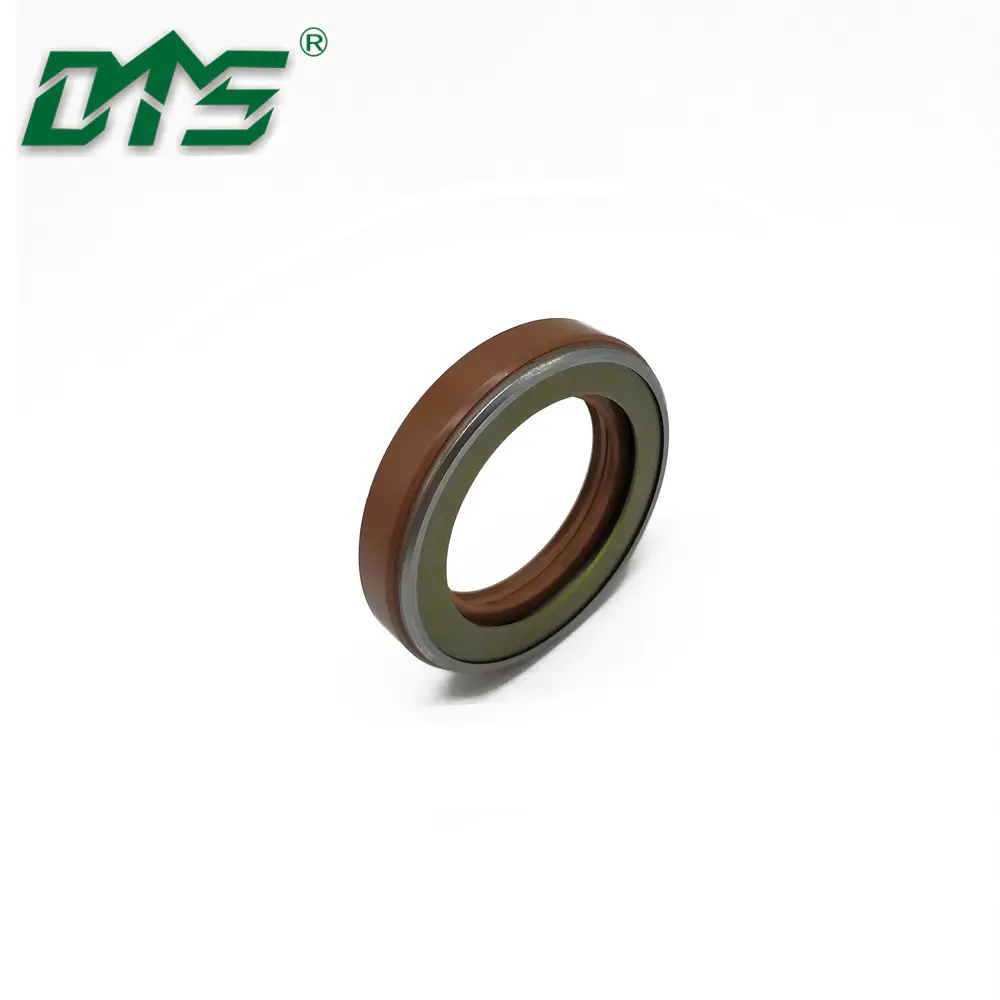

In addition to protecting against contamination, wiper seals also serve as an effective barrier against fluid leakage. Whether it is hydraulic or pneumatic equipment, preventing leaks is essential for maintaining optimal operation. Wiper seals create a tight seal between moving components, such as pistons and cylinders, ensuring that fluids remain contained within their designated areas. This prevents leaks that can lead to system failures, reduced performance, and fluid loss.

Choosing the Right Wiper Seals

1. Material Selection

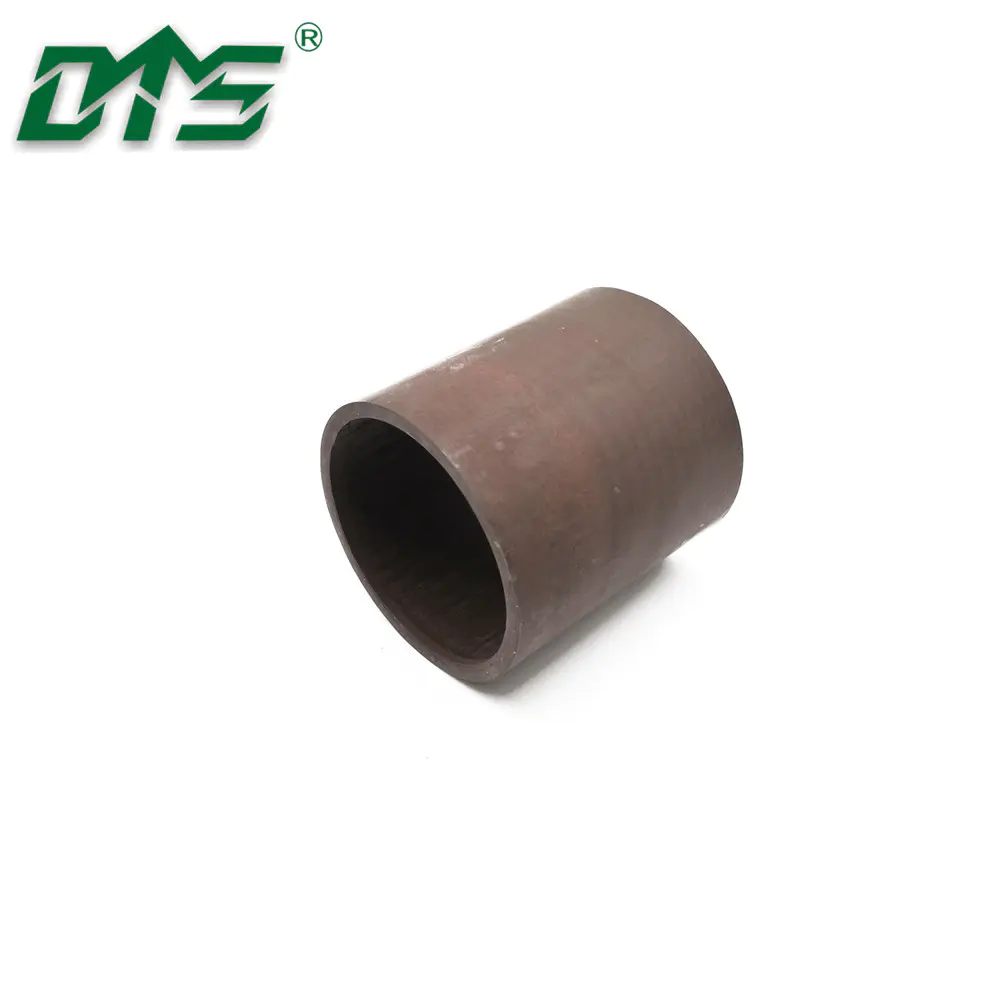

Selecting the appropriate wiper seal material is crucial to achieving optimal performance and durability. High-quality wiper seals are typically made from materials such as polyurethane, nitrile rubber, or fluoroelastomer, all of which offer excellent resistance to environmental factors. Consider the specific application and operating conditions of the equipment to choose the most suitable material for the wiper seals.

2. Design Considerations

Another important aspect when choosing wiper seals is the design. Different equipment components may require specific designs to effectively seal against contamination and reduce friction. For example, wiper seals with scraper lips are designed to remove debris from the surface, ensuring that contaminants do not accumulate and hinder optimal performance. Consulting with wiper seal manufacturers or experts can help in selecting the right design for your equipment.

Benefits of Using High-Performance Wiper Seals

1. Improved Equipment Lifespan

By effectively sealing equipment against contaminants and preventing leakage, high-performance wiper seals contribute to increased equipment lifespan. Equipment that experiences reduced levels of contamination and operates without leaks will require less frequent repairs and replacements. This ultimately translates to reduced downtime and increased productivity for businesses.

2. Enhanced Performance

Wiper seals that are specifically designed for high-performance applications offer superior functionality. They can withstand extreme operating conditions, temperature fluctuations, and high pressures. With enhanced durability and resistance to wear and tear, equipment can operate at its full potential for extended periods, maintaining peak performance throughout its lifespan.

3. Reduced Maintenance Costs

Investing in high-performance wiper seals upfront can lead to significant cost savings over time. By minimizing the risk of contamination and leaks, businesses can avoid major repairs and replacements. Additionally, the extended lifespan of equipment reduces the need for frequent maintenance, resulting in lower labor and material costs associated with upkeep and parts replacement.

4. Increased Operational Efficiency

Equipment downtime due to repairs or replacements can greatly impact business operations. High-performance wiper seals minimize the frequency and extent of such disruptions, ensuring smooth and uninterrupted equipment performance. This, in turn, leads to increased operational efficiency, improved customer satisfaction, and potentially higher profits.

Conclusion

High-performance wiper seals are essential components for extending the lifespan and optimizing the performance of various types of equipment. By preventing contamination, sealing against leakage, and offering superior functionality, these seals contribute to reduced maintenance costs, increased operational efficiency, and improved equipment durability. Businesses should carefully consider the selection of wiper seal materials and designs to ensure compatibility with specific equipment applications. Ultimately, investing in high-quality wiper seals is a wise decision that pays off in the form of enhanced equipment longevity and reliable operation.