Addressing Common Challenges in Rod Seal Selection and Application

Introduction: Understanding the Importance of Rod Seal Selection

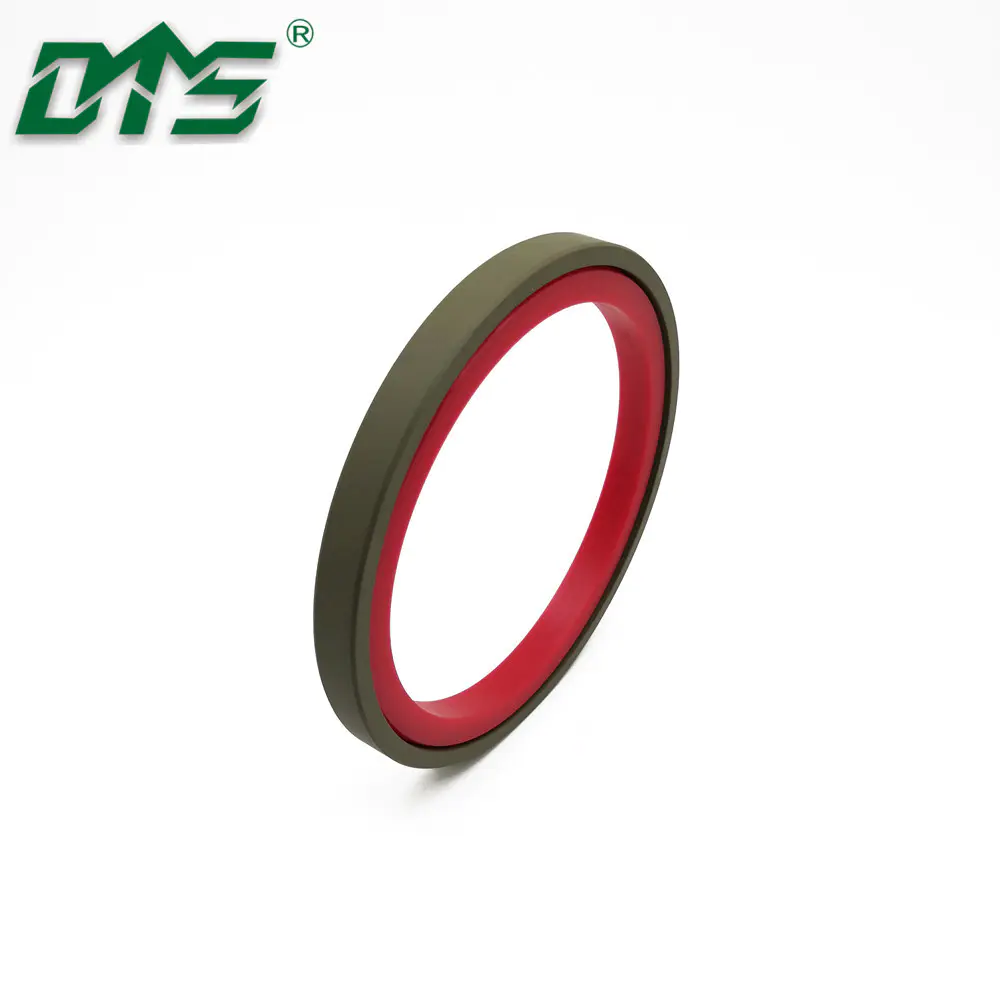

Rod seals are essential components in hydraulic and pneumatic systems, serving as dynamic seals to prevent leakage and contamination. With their primary function of retaining fluid pressure within hydraulic or pneumatic cylinders, rod seals play a vital role in ensuring efficient system functioning. Selecting the right rod seal and applying it correctly is critical for optimal performance, as any shortcomings in these areas can result in system failure, increased maintenance costs, and decreased productivity. This article explores the common challenges associated with rod seal selection and application, offering insights and best practices to tackle these issues effectively.

Common Challenges Faced in Rod Seal Applications

Though rod seal selection may appear straightforward, it often involves complex decision-making processes based on various factors such as operating conditions, temperature range, fluid compatibility, and system pressures. Failing to consider these aspects can lead to numerous challenges in rod seal applications. Some of the most common difficulties faced include premature seal failure, excessive friction, high wear rates, extrusion, and poor sealing performance. These challenges underline the necessity for a systematic approach in seal selection.

Factors for Effective Rod Seal Selection

To overcome the challenges associated with rod seals, engineers and maintenance professionals must assess several critical factors to ensure proper seal selection. Firstly, considering the operating conditions of the application is vital. Parameters such as temperature, pressure range, cylinder speed, and stroke length determine the kind of rod seal required. Additionally, analyzing the type of fluid or medium used is crucial for selecting a seal material compatible with it. Other factors include system cleanliness, expected service life, and the presence of potential contaminants. By evaluating these factors comprehensively, one can determine the most suitable rod seal type and material for their specific application.

Best Practices for Rod Seal Application

While choosing the appropriate rod seal is crucial, correct installation and application practices are equally vital. To ensure successful seals integration and avoid common challenges, several best practices should be followed. Firstly, cleanliness is paramount. Thoroughly clean and inspect all mating surfaces, removing any debris or contamination before installation. Moreover, it is essential to lubricate the seals adequately with a compatible lubricant during installation to avoid damage caused by dry running.

Furthermore, adopting proper installation techniques prevents seal damage during assembly. A controlled, uniform compression is necessary to prevent overstretching or extrusion. Utilizing the correct installation tool, following manufacturer guidelines, and considering the use of seal protectors during assembly can significantly enhance the lifespan of rod seals.

Overcoming Challenges: Tips for Successful Rod Seal Integration

To overcome the challenges associated with rod seal selection and application, certain tips and practices can be employed. Firstly, adhering to preventive maintenance practices is crucial. Regularly inspecting and monitoring seal condition helps detect potential problems early, preventing costly downtime and repairs. Additionally, implementing materials with superior wear resistance or incorporating backup seals for added protection can significantly enhance sealing performance and longevity.

Moreover, ensuring proper system alignment and reduced side loading on the rod is often instrumental in reducing friction and wear on the seal. Proper cylinder alignment using guides and support bearings eliminates misalignment, reducing the risk of seal damage. Lastly, implementing well-designed systems with appropriate pressure control measures, such as pressure relief valves, can prevent excessive pressure spikes, minimizing seal extrusion and damage.

Conclusion:

Addressing common challenges in rod seal selection and application is vital to ensure efficient system performance. Adopting a systematic approach to seal selection, considering various operating factors, and following best installation practices can significantly improve sealing performance, increase system lifespan, and reduce maintenance costs. By overcoming challenges and implementing best practices, engineers and maintenance professionals can optimize rod seal integration, enhancing the overall effectiveness of hydraulic and pneumatic systems.