Why Scraper Seals Are Essential in Industrial Machinery

Why Scraper Seals Are Essential in Industrial Machinery

If you work in the industrial machinery sector or are involved in the manufacturing industry, you are likely familiar with the importance of equipment maintenance and regular check-ups. Keeping machinery running smoothly and efficiently is crucial to ensure that production stays on track and that the bottom line is met.

One of the essential parts of machinery maintenance is ensuring that equipment is sealed correctly, and one crucial component of that sealing system is scraper seals. This article will explore why scraper seals are essential in industrial machinery, how they work, and what benefits they provide.

What are Scraper Seals?

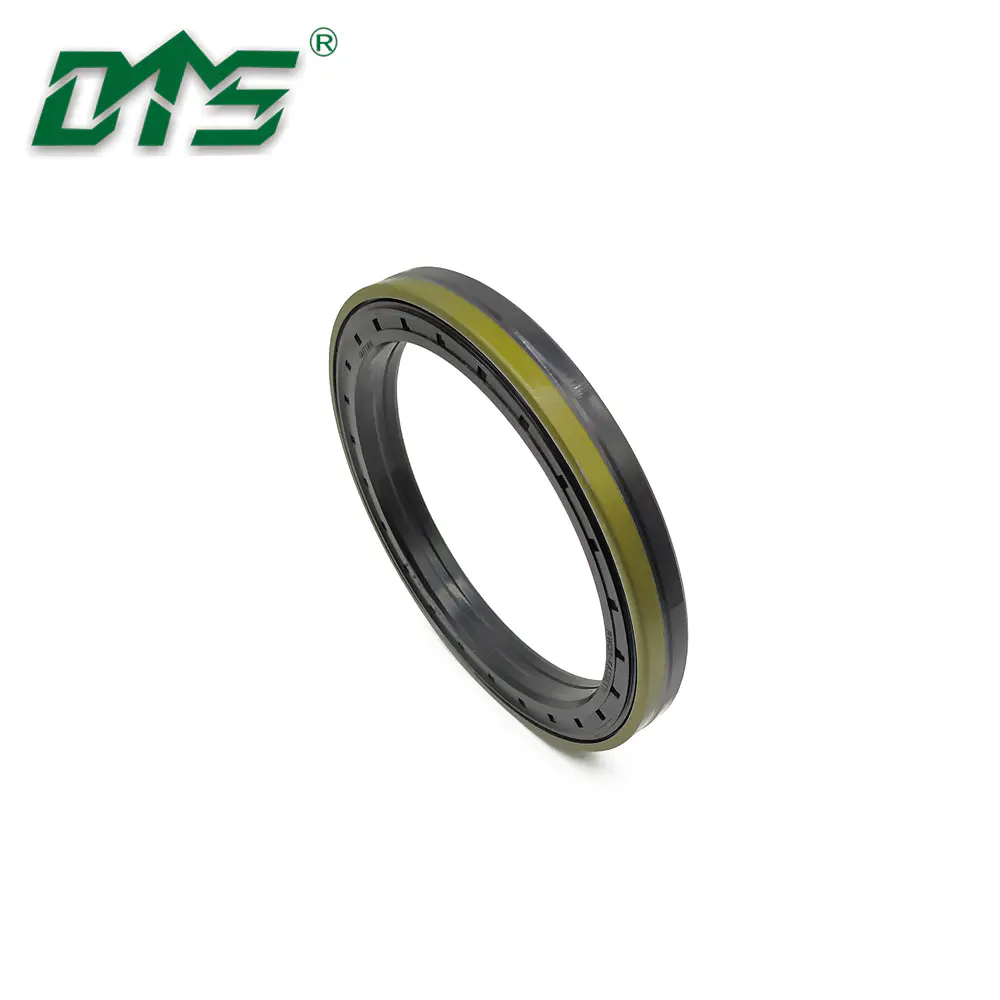

Scraper seals are an essential component of machinery sealing systems, generally used to prevent contamination and protect bearings, rods, and other equipment from abrasives, dust, and moisture. They are called scraper seals because they scrape any buildup or debris that would otherwise cause damage or wear.

There are several types of scraper seals, including lip seals, labyrinth seals, and felt seals. Each type of scraper seal is designed to perform a specific function, and the right type for your machinery depends on factors like the speed of the equipment, the type of contaminants in the environment, and the overall design of the machinery.

Why Are Scraper Seals Essential?

Scraper seals are essential in industrial machinery for several reasons.

Preventing equipment damage: One of the most critical functions of scraper seals is preventing damage to expensive machinery parts. Scraper seals ensure that contaminants like dust and debris do not enter these parts, keeping them clean, and reducing the potential for wear and damage.

Reducing downtime and maintenance costs: Scraper seals reduce downtime and maintenance costs since they minimize the damage caused by contaminant buildup, allowing machinery to run smoothly for more extended periods. If unchecked, buildup can cause machinery to break down or malfunction, leading to increased repair and replacement costs, and slower production times.

Increasing productivity and efficiency: Scraper seals help maintain efficiency and productivity by keeping machinery clean and free from debris and other contaminants. This ensures that parts work optimally and reduces friction, leading to smoother operation and improved performance.

How Do Scraper Seals Work?

Different types of scraper seals work in different ways, but generally, a scraper seal is designed to fit tightly around a moving component, creating a barrier that prevents anything from entering the internal part of the machinery.

Lip seals are one of the most common types of scraper seals and work by creating a seal through compression between the seal and the component they are sealing around. The tight fit also creates a wiping action that removes any contaminants and debris that may have penetrated the seal.

Labyrinth seals are another type of scraper seal that uses multiple barriers and a maze-like design to block contaminants from entering machinery components. The design of labyrinth seals consists of multiple grooves, creating a tortuous path that particles must travel before reaching the component they intend to penetrate.

Felt seals are scrapers made from felt materials and are often used to seal slower-moving components. They provide excellent dust sealing capabilities and are ideal for environments where abrasive or particulate contaminants are present.

Benefits of Using Scraper Seals

Scraper seals provide many benefits when used in industrial machinery applications:

They reduce friction between components, allowing machinery to operate more smoothly and efficiently.

They prevent contaminants from entering machinery components, reducing the risk of equipment damage and wear.

They reduce the need for maintenance and repair, reducing equipment downtime and saving on maintenance costs.

They help prolong the life of machinery components since they protect them from wear and tear.

They improve the overall efficiency and productivity of machinery, contributing to a more streamlined production process.

Conclusion

Scraper seals are an essential component of sealing systems in industrial machinery, used to prevent contamination, promote machinery health, and increase the overall efficiency of equipment. They are used in various applications to prevent damage, reduce maintenance requirements, and improve productivity.

Investing in high-quality scraper seals and regular maintenance checks can go a long way in keeping machinery operating optimally and reducing long-term maintenance costs. By prioritizing scraper seals as an integral part of overall machinery maintenance, owners can extend the life of their equipment and ensure a smoother and more efficient production process.