Why Rubber Oil Seals are Essential for Machinery Performance

Rubber Oil Seals: Protecting Machinery and Improving Performance

Machinery performance is an integral aspect of industrial processes and the production chain. For machinery to function optimally, the components must also function at their peak. One critical component that affects machinery performance and longevity is the seal. Rubber oil seals are crucial elements that protect machinery from external elements, including dust, water, and other contaminants. They also ensure that lubricants and other fluids remain contained within the machinery's system, minimizing leaks and reducing the risks of downtime. In this article, we will discuss why rubber oil seals are essential for machinery performance.

What Are Rubber Oil Seals?

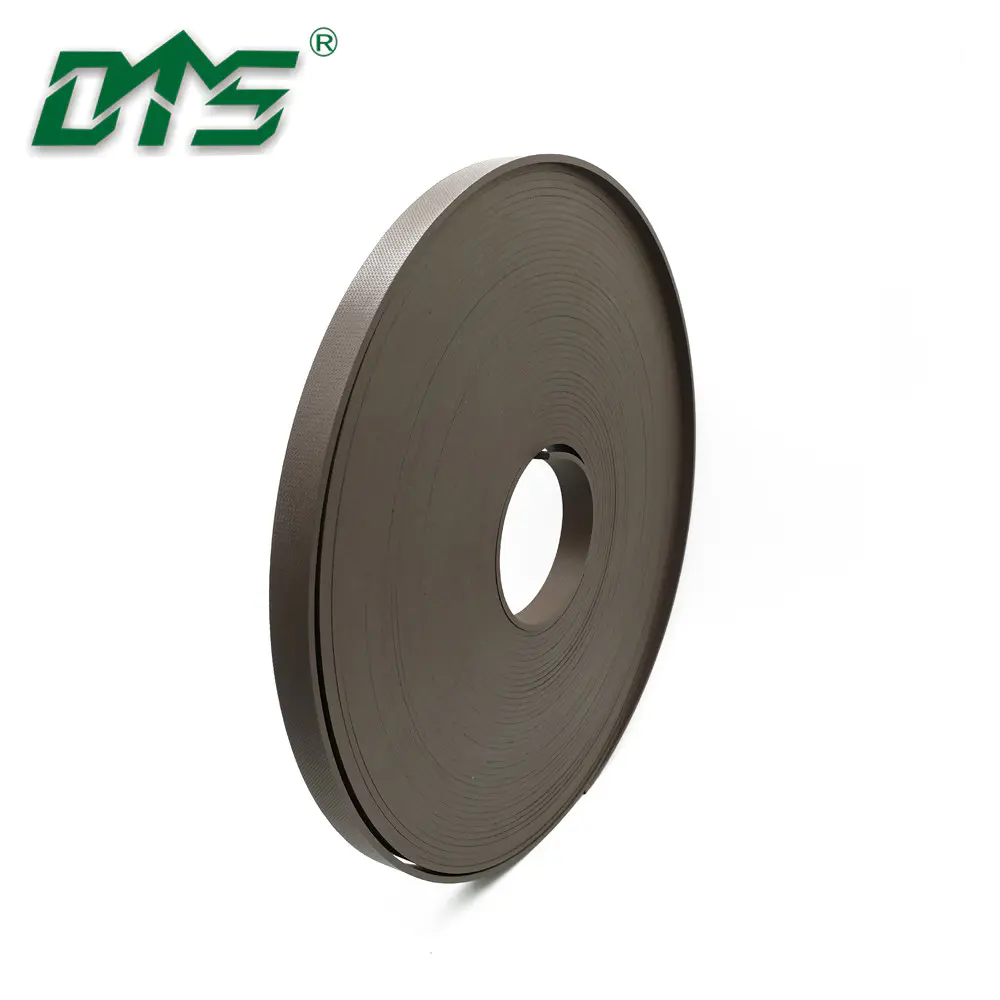

Rubber oil seals are mechanical components used to prevent the leakage of fluids in machinery systems. They are round or square-shaped, depending on the machinery's design, and are made of rubber materials with different hardness ratings. The rubber materials provide a pliable, tight seal that prevents lubricants, coolants, and other fluids from escaping the machinery's systems. Rubber oil seals are used in various applications, including automotive, marine, and aerospace industries, to protect machinery components and ensure their optimal performance.

Why Are Rubber Oil Seals Essential?

1. Protection from Contaminants

Machinery components are vulnerable to external elements such as dust, water, and other contaminants that can cause damage, reduce their efficiency and longevity. Rubber oil seals protect machinery components from these external elements, ensuring that they remain fully functional for longer. By keeping contaminants out, these seals significantly reduce the possibility of premature machinery failure and the risks of downtime.

2. Prevention of Fluid Leaks

Fluid leaks are a common problem in machinery systems that use lubricants and other fluids. Leaks can cause significant damage to machinery components and reduce performance, leading to costly downtime. Rubber oil seals offer an effective solution to this problem by preventing fluid leaks from machinery systems. They ensure that fluids remain contained, reducing the risk of machine breakdowns, extending their durability and performance.

3. Maintenance of Lubrication Levels

Lubrication is essential to machinery performance and longevity. Without proper lubrication, machinery components suffer from wear and tear, leading to premature failure and reduced performance. Rubber oil seals help maintain lubrication levels within machinery systems, ensuring that machinery components operate efficiently and last longer. By keeping fluids contained and preventing leaks, these seals also ensure that lubricants remain within the system for longer, reducing the need for frequent maintenance and top-up.

4. Reduced Friction and Heat

Friction and heat are common problems in machinery systems that can cause significant damage to components and reduce performance. Rubber oil seals help reduce friction within machinery systems, allowing components to move smoothly and efficiently. They also help dissipate heat generated by machinery components, preventing overheating and wear and tear. By reducing friction and heat, these seals improve machinery performance and reduce the need for frequent repairs and maintenance.

5. Cost-Effective Solution

The cost of repairing and replacing machinery components can be significant, leading to losses in productivity and revenue. Rubber oil seals provide a cost-effective solution to machinery maintenance, reducing the need for frequent repairs and replacements. By extending machinery life and reducing the risks of downtime, these seals help businesses save money in the long run, improving their bottom line and profitability.

Conclusion

Rubber oil seals are essential components for protecting machinery from contaminants, preventing fluid leaks, maintaining lubrication levels, reducing friction, heat, and costs. They are a simple but effective solution to maintain machinery performance and increase longevity. Investing in high-quality rubber oil seals can significantly improve machinery performance, reduce downtime and repair costs, and ensure businesses stay competitive in the marketplace.