What are rubber oil seals?

What Are Rubber Oil Seals?

When it comes to machinery and engines, there are multiple parts and components that ensure smooth operation and long-term functioning. One of these essential components is rubber oil seals. As the name suggests, these seals are designed to keep oil and lubricants in their designated spaces and prevent them from leaking out into other parts of the machinery. Overall, they help in reducing friction and wear and tear while also ensuring better energy efficiency. In this article, we will explore the various aspects of rubber oil seals - their types, function, applications, and advantages.

Types of Rubber Oil Seals

Rubber oil seals are available in different types, each serving a specific function. Here are some of the most common types:

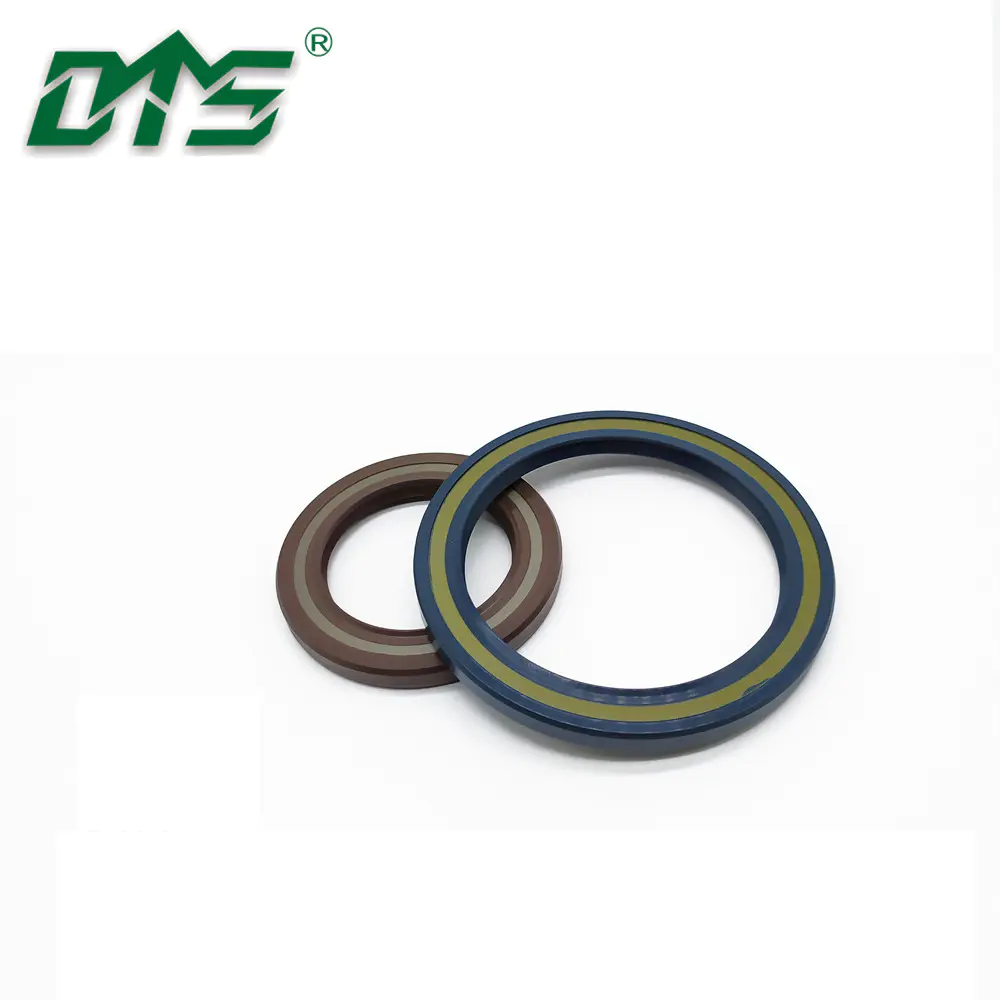

1. Rotary Shaft Seals - These seals are used to prevent oil and other lubricants from leaking out of rotary shafts. They are designed to seal the end of the shaft and the housing in which it is mounted. Rotary shaft seals come in different designs such as lip seals, labyrinth seals, and mechanical seals.

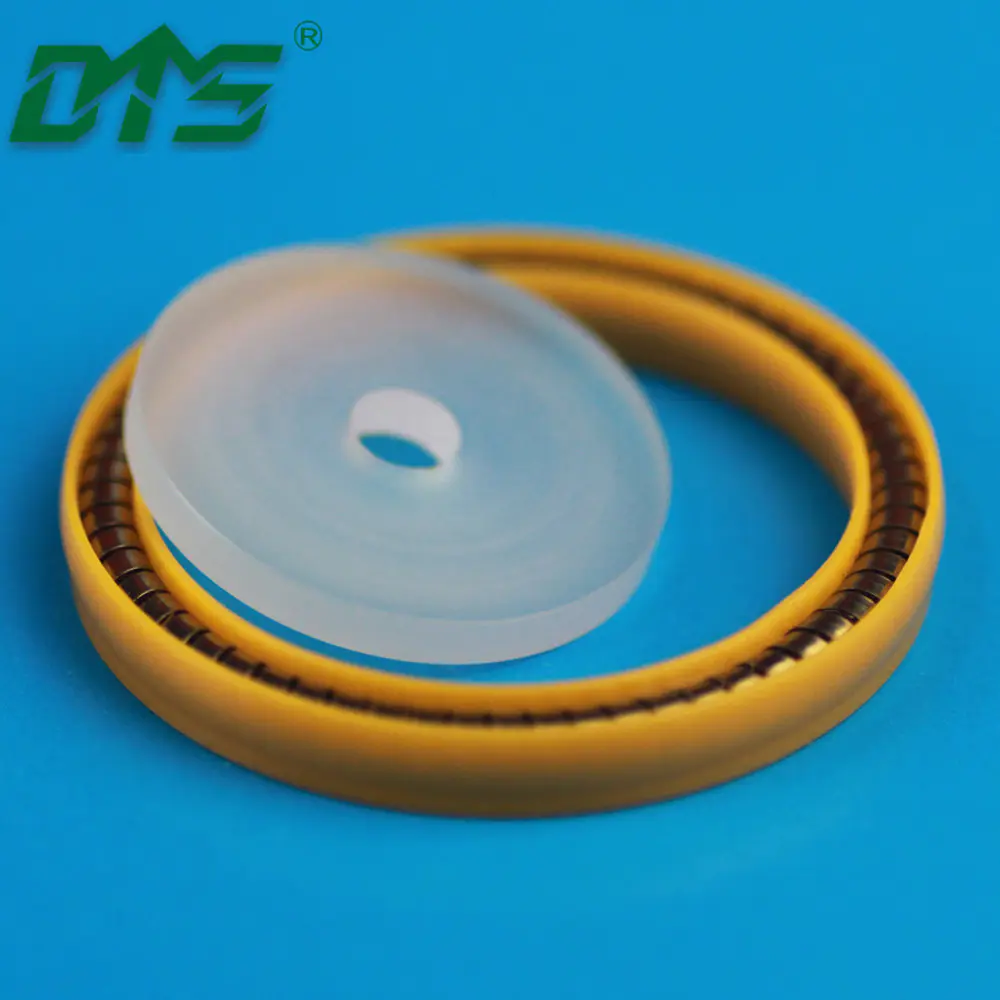

2. Piston Seals - Piston seals are used in hydraulic and pneumatic cylinders. They are designed to prevent the hydraulic fluid or air from escaping the cylinder while the piston is in motion.

3. Wiper Seals - Wiper seals are used in conjunction with piston seals. They are often placed behind the piston seal and help in wiping off dirt and debris from the rod before it enters the cylinder.

4. O-ring Seals - O-ring seals are circular seals that are used in a wide variety of applications. They are typically made of rubber or silicone and are used to seal fluids and gases in machinery, instruments, and other objects.

5. Bearing Seals - Bearing seals are used to prevent contaminants such as dirt, dust, and moisture from entering the bearing assembly. This helps in extending the life of the bearing and ensures smooth operation.

Functions of Rubber Oil Seals

The primary purpose of rubber oil seals is to prevent lubricants from leaking out of a machine or engine. However, they perform some other critical functions as well. Here are some of them:

1. Reduce Friction - Rubber oil seals help in reducing friction by keeping the oil and lubricants in their designated places. This, in turn, reduces the wear and tear on the machinery and engine parts.

2. Improve Energy Efficiency - By reducing friction, rubber oil seals help in improving energy efficiency. A machine with reduced friction will require less energy to operate, resulting in lower energy costs.

3. Protect Against Contaminants - Rubber oil seals protect machinery and engines from contaminants such as dirt, dust, and moisture. This helps in extending the life of the machine and engine parts and reduces the chances of breakdowns.

4. Maintain Consistency - Rubber oil seals ensure that the oil and lubricants are present in the right quantity and consistency. This helps in ensuring that the machine and engine parts operate smoothly and efficiently.

Applications of Rubber Oil Seals

Rubber oil seals are used in a wide variety of applications. Here are some of the most common ones:

1. Automotive Industry - Rubber oil seals are extensively used in the automotive industry to seal different engine parts such as crankshafts, camshafts, and transmission shafts.

2. Aerospace Industry - Rubber oil seals are used in aircraft engines to prevent lubricants from leaking out and to protect against contaminants.

3. Manufacturing Industry - Rubber oil seals are used in different manufacturing processes to prevent leakage of fluids and protect machinery against contaminants.

4. Construction Industry - Rubber oil seals are used in construction machinery to prevent lubricant leakage and protect against contaminants.

5. Marine Industry - Rubber oil seals are extensively used in the marine industry on ships and boats to prevent leakage of lubricants and protect against saltwater corrosion.

Advantages of Rubber Oil Seals

Rubber oil seals come with several advantages that make them an essential component in machinery and engines. Here are some of them:

1. Durability - Rubber oil seals are designed to withstand high temperatures, pressure, and wear and tear. This makes them long-lasting and durable.

2. Cost-Effective - Rubber oil seals are cost-effective when compared to other sealing materials such as metals or plastics.

3. Easy Installation - Rubber oil seals are easy to install and replace, which reduces downtime and maintenance costs.

4. Versatility - Rubber oil seals can be designed to fit different shapes and sizes, making them suitable for a wide variety of applications.

Conclusion

Rubber oil seals are an essential component in machinery and engines. They prevent leakage of lubricants, reduce friction and wear and tear, and protect against contaminants. With multiple types, functions, applications, and advantages, rubber oil seals are a versatile and cost-effective sealing solution that ensures smooth operation and long-term functioning of machinery and engines.