What are hydraulic seals used for?

Introduction to Hydraulic Seals

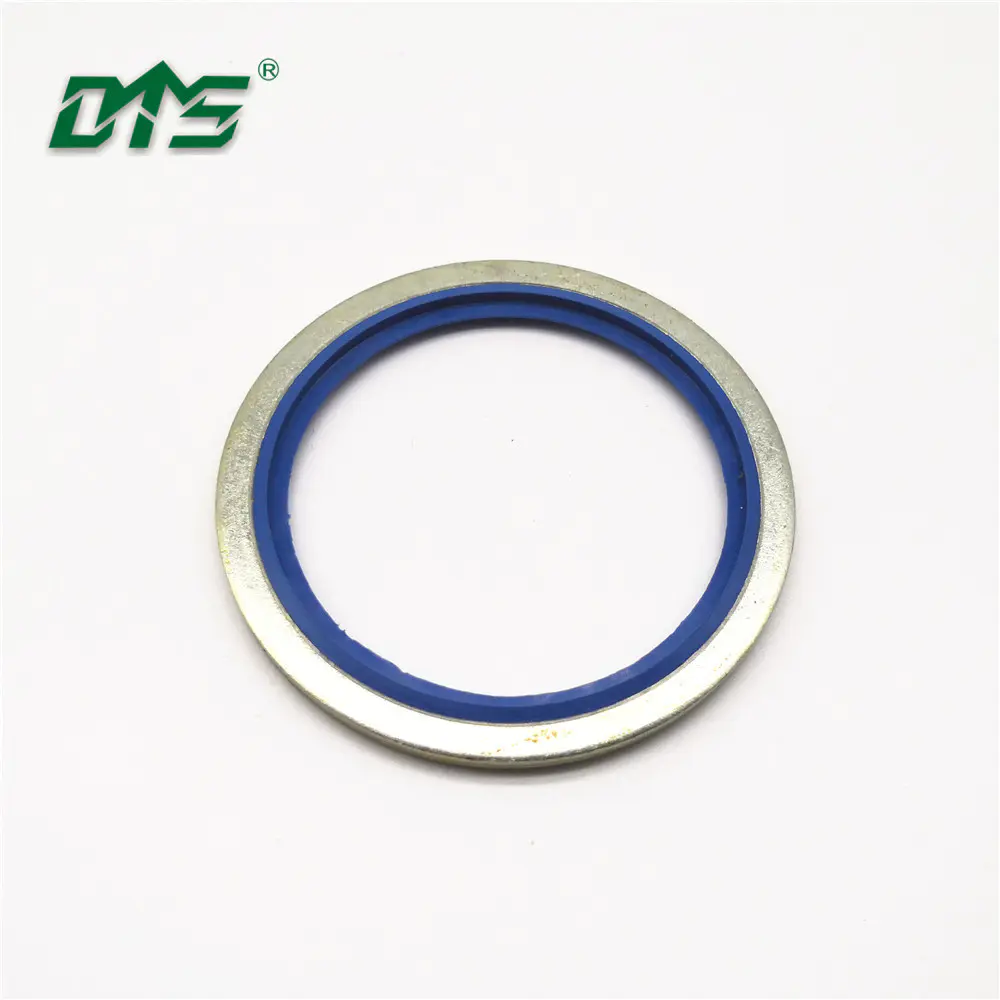

Hydraulic seals play a vital role in the functioning of hydraulic systems. They are designed to prevent the leakage of fluid from cylinders and pumps, ensuring that the system works efficiently and safely. When it comes to selecting the right hydraulic seal for your application, there are a few key factors to consider. In this article, we will take a closer look at hydraulic seals, including their types, applications, and benefits.

Types of Hydraulic Seals

There are various types of hydraulic seals available in the market, each designed for specific applications. Some of the commonly used hydraulic seals include:

1. Piston seals – These seals are used to prevent the leakage of fluid between the piston head and cylinder wall in hydraulic cylinders.

2. Rod seals – Rod seals are designed to prevent the leakage of fluid between the cylinder head and piston rod.

3. Wiper seals – Wiper seals are used to scrape dirt or contaminants from the piston rod, preventing them from entering the hydraulic system.

4. Excluder seals – These seals are designed to prevent the ingress of external substances such as dust, dirt, or water, into the hydraulic system.

5. Guide rings – Guide rings are intended to provide stability to the piston rod, ensuring it moves in a linear path with minimal friction.

Applications of Hydraulic seals

Hydraulic seals are used in various applications across industries, including automotive, construction, aerospace, and manufacturing. They play an essential role in ensuring that hydraulic systems function safely and efficiently. Some of the common applications of hydraulic seals include:

1. Automotive – Hydraulic seals are used in various automobile applications, including brake systems, power steering systems, transmission systems, and suspension systems.

2. Construction – Hydraulic seals are used in construction equipment such as excavators, loaders, and bulldozers to control and maintain the hydraulic fluid within the system.

3. Aerospace – Hydraulic systems are widely used in the aerospace industry, and hydraulic seals play a crucial role in ensuring the safe and efficient operation of these systems.

4. Manufacturing – Hydraulic seals are used in various manufacturing processes, including injection molding machines, hydraulic presses, and food processing equipment.

Benefits of Hydraulic Seals

Hydraulic seals offer several benefits, including:

1. Leak prevention – Hydraulic seals ensure that there is no leakage of hydraulic fluid from the system, preventing damage to equipment and ensuring smooth operation.

2. Reduced friction – Hydraulic seals reduce friction between moving parts in the system, allowing for more efficient operation and increased equipment lifespan.

3. Temperature stability – Hydraulic seals are designed to withstand high temperatures and ensure that the system operates reliably even in extreme conditions.

4. Chemical resistance – Hydraulic seals are resistant to various chemicals, making them suitable for use in harsh environments.

5. Easy installation – Hydraulic seals are easy to install, allowing for quick servicing and maintenance of hydraulic systems.

Conclusion

Hydraulic seals are a critical component in ensuring the safe and efficient operation of hydraulic systems. With various types of hydraulic seals available in the market, it is essential to consider factors such as application, temperature, and chemical resistance when selecting the right seal for your system. By choosing the appropriate hydraulic seal and properly maintaining it, you can ensure that your hydraulic system operates reliably and efficiently for years to come.