Selecting the Right Hydraulic Piston Seals for Your Equipment

Selecting the Right Hydraulic Piston Seals for Your Equipment

Introduction

The success of hydraulic systems relies heavily on the proper functioning of various components, including piston seals. These seals play a critical role in preventing fluid leakage and maintaining the system's efficiency. Selecting the right hydraulic piston seals is essential for ensuring optimal performance and prolonging the lifespan of your equipment. In this article, we will delve into the factors to consider when choosing piston seals and provide valuable insights to help you make an informed decision.

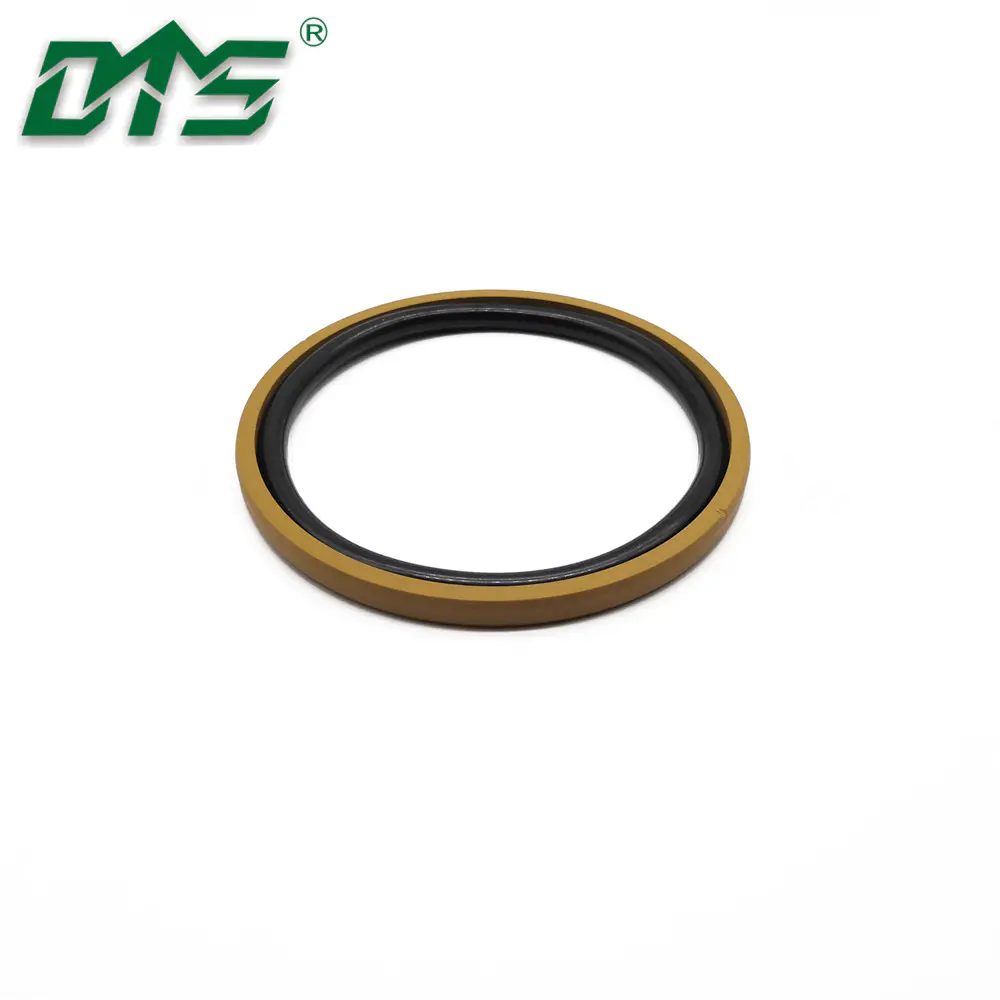

Types of Piston Seals

Piston seals come in various types, each with its own advantages and limitations. It is crucial to understand these types to determine which one would be the most suitable for your equipment.

1. Single-Acting Piston Seals: These seals are specifically designed for applications where hydraulic pressure acts on one side of the piston. They are effective in preventing fluid leakage and maintaining system efficiency.

2. Double-Acting Piston Seals: As the name suggests, these seals are suitable for applications where hydraulic pressure acts on both sides of the piston. They provide excellent sealing ability, ensuring balanced performance.

3. Symmetrical Piston Seals: These seals are versatile and can be used in both single- and double-acting hydraulic systems. They offer excellent sealing performance and are known for their durability.

4. U-Cup Seals: U-cup seals, also known as U-seals or lip seals, are commonly used in hydraulic cylinders. They are popular due to their simplicity in design and effective sealing capabilities.

5. Labyrinth Seals: Labyrinth seals consist of a series of interlocking grooves that prevent fluid leakage. These seals are widely used in applications where high-pressure differentials are involved.

Materials Used in Piston Seals

The choice of material for piston seals depends on several factors such as the operating conditions, temperature, pressure, and the type of fluid being used in the hydraulic system. Some commonly used materials in piston seals include:

1. Nitrile (Buna-N): Nitrile is a cost-effective material suitable for applications with moderate temperature and pressure conditions. It offers good resistance to hydraulic fluids and is known for its durability.

2. Polyurethane (PU): Polyurethane seals are widely used due to their excellent hydraulic oil resistance and high abrasion resistance. They can withstand demanding operating conditions and are ideal for heavy-duty applications.

3. Fluoroelastomer (FKM): FKM seals exhibit high compatibility with various hydraulic fluids and can withstand extreme temperatures. They are ideal for applications that involve aggressive fluids or high-temperature environments.

4. Ethylene Propylene Diene Monomer (EPDM): EPDM seals offer good resistance to water, steam, and phosphate ester hydraulic fluids. They are commonly used in applications that require resistance to weathering and ozone.

5. Polytetrafluoroethylene (PTFE): PTFE seals have low friction properties and are known for their excellent chemical resistance. They are suitable for applications with demanding operating conditions and corrosive fluids.

Factors to Consider When Selecting Piston Seals

When choosing hydraulic piston seals for your equipment, it is essential to consider the following factors:

1. Operating Conditions: Assess the temperature range, pressure levels, and speed of your hydraulic system. These factors will determine the type of seal that can effectively withstand the conditions without compromising performance.

2. Fluid Compatibility: Consider the type of fluid used in the hydraulic system. Different seals are designed to withstand different fluids. Ensure compatibility between the chosen seal material and the fluid to prevent degradation or premature failure.

3. Seal Performance: Evaluate the seal's ability to resist extrusion, wear, and leakage. The seal should be able to maintain tight contact with the cylinder wall and effectively prevent fluid from escaping the system.

4. Installation and Maintenance: Consider the ease of installation and maintenance for the selected seal. Some seals may require special tools or expertise for installation or periodic maintenance.

5. Cost-Effectiveness: While it is crucial to choose a seal that meets the system's requirements, considering the cost-effectiveness is also important. Balancing performance with affordability will help optimize the selection process.

Installation and Maintenance Tips for Piston Seals

Proper installation and regular maintenance are crucial for ensuring optimal performance and longevity of hydraulic piston seals. Here are some essential tips to follow:

1. Cleanliness: Ensure all components, including the cylinder, piston, and seal housing, are thoroughly cleaned before installing the piston seal. Any contaminants can impair sealing performance and lead to premature failure.

2. Lubrication: Apply a compatible lubricant to the piston seal before installation. This will help reduce friction, ease installation, and enhance sealing performance.

3. Correct Alignment: Ensure proper alignment of the piston and cylinder during installation. Misalignment can cause uneven stress on the seal, leading to leakage or seal damage.

4. Regular Inspection: Perform regular inspections to check for any signs of wear, extrusion, or degradation. Replace the piston seal if any abnormalities are detected to prevent potential system failure.

5. Follow Manufacturer Guidelines: Always refer to the manufacturer's guidelines for installation, maintenance, and replacement. Following these guidelines ensures the seals perform optimally and prolongs their lifespan.

Conclusion

Selecting the right hydraulic piston seals is crucial for the efficient operation of your equipment. Consider the operating conditions, fluid compatibility, seal performance, installation, and maintenance aspects to make an informed decision. By choosing the appropriate piston seals and following proper installation and maintenance procedures, you can enhance the reliability, performance, and longevity of your hydraulic system. Remember, investing in high-quality piston seals is a worthy investment towards maximizing productivity and minimizing downtime.