Oil Seal Ring Replacement: Steps for a Seamless Upgrade

Oil Seal Ring Replacement: Steps for a Seamless Upgrade

Introduction

Understanding the Importance of an Oil Seal Ring

Selecting the Right Oil Seal Ring for Replacement

Tools Required for Oil Seal Ring Replacement

Step-by-Step Guide for Replacing an Oil Seal Ring

Conclusion

Introduction

An oil seal ring plays a crucial role in maintaining the efficiency and proper functioning of various mechanical systems. It acts as a barrier, preventing the leakage of oil or fluids from one chamber to another. Over time, due to wear and tear, these seals can deteriorate, causing oil leaks and potential damage to surrounding components. To ensure optimal performance and prevent costly repairs, it is essential to replace worn-out oil seal rings with new ones. In this article, we will discuss the steps involved in replacing an oil seal ring, providing a seamless upgrade to your machinery.

Understanding the Importance of an Oil Seal Ring

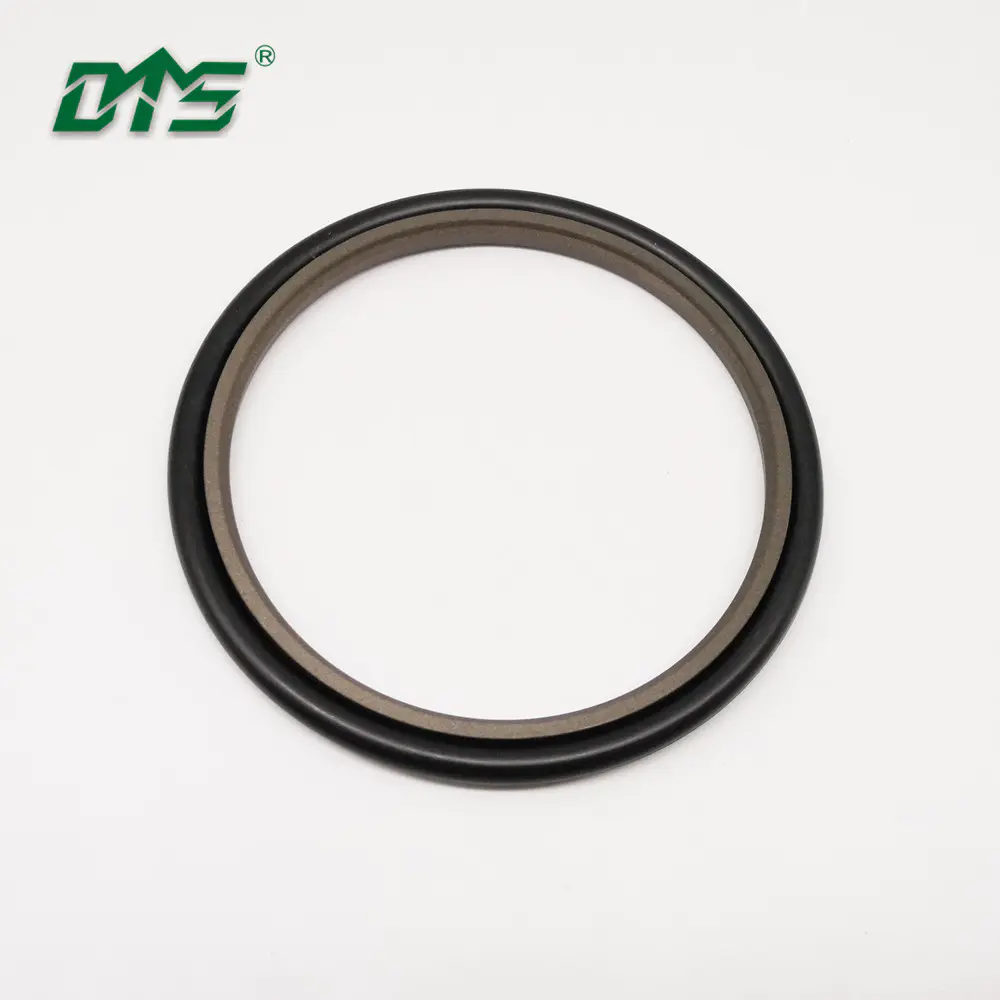

An oil seal ring, also known as a shaft seal, resides in the housing bore and encircles the rotating shaft, preventing oil leakage. It comprises a sealing lip made of a durable material such as rubber or silicone, designed to create a tight seal. These seals are commonly found in engines, transmissions, pumps, and other mechanical systems, where they keep oil inside designated compartments and prevent contaminants from entering. A faulty oil seal ring can result in oil loss, decreased lubrication, and even contamination, leading to equipment failure. Therefore, regular maintenance and timely replacement of oil seal rings are crucial.

Selecting the Right Oil Seal Ring for Replacement

Before embarking on the oil seal ring replacement process, it is vital to choose the correct replacement part. Oil seal rings come in various sizes and materials to suit different applications. To ensure a proper fit, it is essential to refer to the manufacturing specifications and consult the equipment manual. Identifying the right seal size, type, and material will guarantee optimal performance and prevent any potential issues. It is recommended to source oil seal rings from reputable suppliers or manufacturers to ensure quality and compatibility.

Tools Required for Oil Seal Ring Replacement

Replacing an oil seal ring requires the use of specific tools to simplify the process and ensure accuracy. Here are the essential tools you will need for a successful replacement:

1. Screwdrivers: A set of flathead and Phillips screwdrivers will be required to remove screws and fasteners holding the housing or components in place.

2. Pliers: Needle-nose pliers or snap-ring pliers are necessary for removing retaining rings, snap rings, or circlips that secure the oil seal.

3. Pry Bar: A pry bar helps gently remove the old oil seal ring without damaging the surrounding components.

4. Rubber Mallet: A rubber mallet can be used to tap the new oil seal ring into its proper position, ensuring a tight fit.

5. Seal Puller: In some cases, stubborn oil seal rings may require a seal puller to be removed safely.

6. Cleaning Solvent: A suitable cleaning solvent should be used to thoroughly clean the sealing area before installing the new oil seal ring.

It is essential to have all the necessary tools readily available before starting the replacement process to avoid any delays or difficulties.

Step-by-Step Guide for Replacing an Oil Seal Ring

Now, let's dive into the step-by-step process of replacing an oil seal ring, ensuring a seamless upgrade to your machinery.