Is oil seal a gasket?

Is Oil Seal a Gasket?

Introduction:

In the realm of mechanical engineering and automotive technology, several terms and components might seem interchangeable, leading to confusion. One particular area where this confusion arises is in understanding the difference between an oil seal and a gasket. While both are essential components used to prevent leakage and ensure the efficient functioning of various machinery, they differ in design, purpose, and application. This article aims to explore the characteristics and functions of oil seals and gaskets, highlighting their differences and shedding light on their respective roles in mechanical systems.

Oil Seals: An Overview

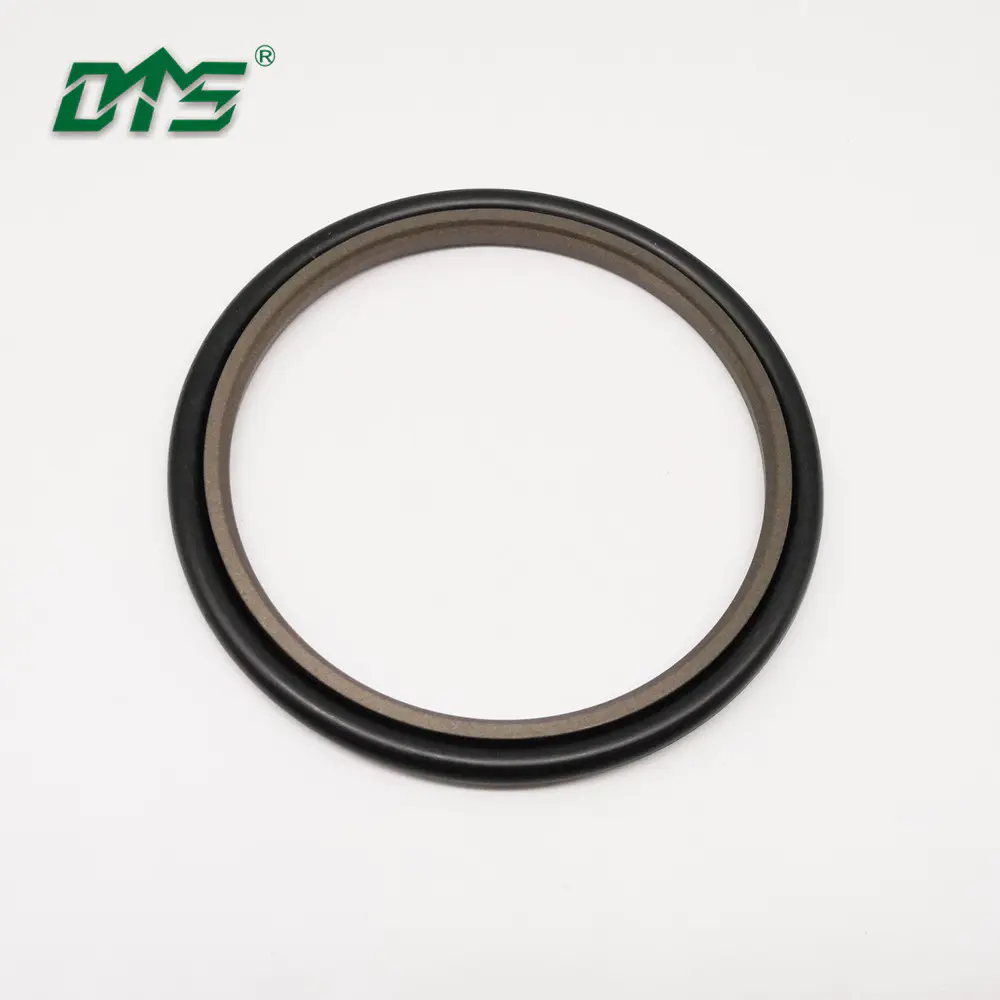

Oil seals, also known as shaft seals or rotary seals, are mechanical components primarily used to prevent oil leakage and contamination in rotating or reciprocating machinery. These seals are designed to fit around a rotating shaft tightly, creating a barrier that prevents lubricants from escaping while preventing dirt, debris, or other contaminants from entering the system. Oil seals are commonly used in various applications such as engines, gearboxes, pumps, and axles, where they play a crucial role in maintaining the integrity and performance of the machinery by reducing friction and wear on moving parts.

Design and Construction:

Oil seals are typically composed of a flexible and elastic material, such as rubber, which is bonded to a metallic ring or case. The rubber lip, which is the primary sealing element, is in direct contact with the rotating shaft, creating a secure seal. The metal casing provides structural support and facilitates the installation of the seal within the housing. The choice of material for oil seals depends on factors such as operating conditions, temperature, and the type of fluid or lubricant being sealed.

Functions and Features:

The primary function of an oil seal is to prevent lubricants, such as oil or grease, from leaking out of the system. By maintaining the oil's integrity, these seals ensure that the machinery operates smoothly and efficiently. Oil seals also prevent the entry of external contaminants, including dust, dirt, water, or chemicals, which could compromise performance or lead to premature component failure. The lip design of oil seals ensures a tight fit on the shaft, reducing friction and preventing oil slippage or degradation.

Installation and Maintenance:

Proper installation of oil seals is crucial to ensure their effectiveness. The surface of the shaft should be clean and free from any burrs or irregularities that could damage the seal. Lubricating the lip of the seal during installation aids in proper fitting and helps increase its longevity. Regular inspection and maintenance of oil seals are necessary to prevent leaks and ensure optimal performance. Signs of wear, including cracks, lip deformation, or loss of elasticity, should be addressed promptly by replacing the seal.

Gaskets: An Overview:

In contrast to oil seals, gaskets are static sealing components that are commonly used to prevent leakage between two stationary parts. Gaskets are employed in a wide range of applications, including engines, pipelines, heat exchangers, and fluid systems, where they create a reliable seal between two mating surfaces. Unlike oil seals, gaskets do not experience relative motion but must provide a secure barrier against leaks, ensuring the integrity of a system or component.

Types and Construction:

Gaskets come in various designs and materials to accommodate specific applications and operating conditions. Some commonly used gasket materials include rubber, cork, metal, fiber, and composite materials. These materials are chosen based on factors such as temperature, pressure, chemical compatibility, and desired flexibility. Gaskets can be classified into four main types: sheet gaskets, spiral wound gaskets, ring gaskets, and solid material gaskets, each serving unique purposes.

Functions and Features:

Gaskets serve the critical function of closing the gap between mating surfaces, preventing the leakage of fluids or gases. They provide a reliable, long-lasting seal even under high compression or fluctuating temperatures. Gaskets can compensate for irregularities or imperfections on the mating surfaces, ensuring a tight fit and preventing leaks. Additionally, gaskets serve as an effective barrier against corrosion, vibration, and environmental factors.

Installation and Maintenance:

Proper installation and maintenance of gaskets are crucial to prevent leaks and ensure the overall performance of a system. Gaskets should be carefully positioned between the mating surfaces, ensuring that they are centered and aligned correctly. Applying the correct tightening torque or clamping force is essential to achieve an optimal seal. Regular inspection and replacement of gaskets are necessary, especially when signs of wear, degradation, or leakage become apparent.

Conclusion:

Although oil seals and gaskets both contribute to preventing leakage and ensuring the efficiency of mechanical systems, they differ significantly in terms of design, function, and application. Oil seals are primarily used to prevent lubricant leakage and dirt ingress in rotating or reciprocating machinery, while gaskets create a static seal between two stationary parts. Understanding the distinctions between these essential components allows engineers and technicians to select and implement the most appropriate solution for various applications, improving the reliability and performance of mechanical systems.