Innovative Uses of Rubber Oil Seals in Industrial Applications

by:DMS Seals

2023-06-02

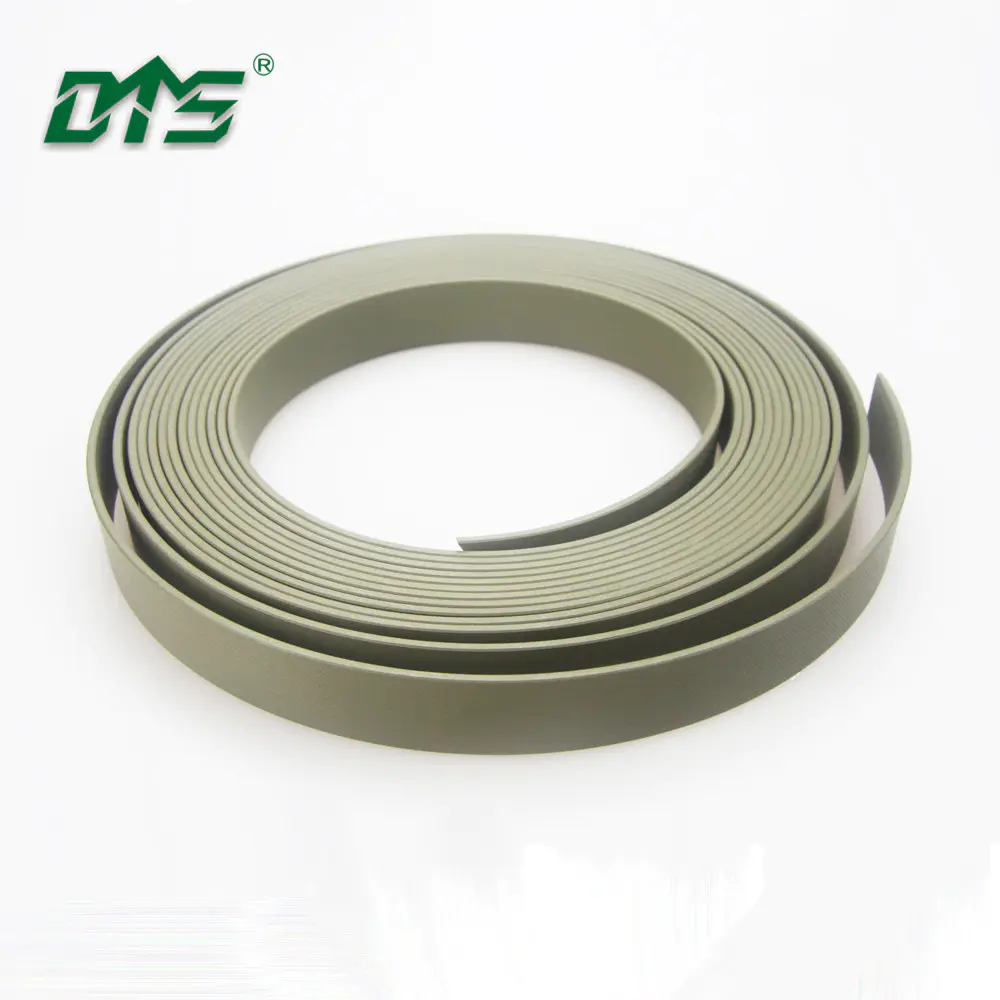

Rubber oil seals may seem like a small and insignificant component of industrial machinery, but they play a crucial role in preventing leaks and ensuring smooth operation. These simple yet innovative devices are used across various industries for sealing rotating shafts or hydraulic cylinders to prevent the escape of lubricating fluids or gases. In this blog post, we will explore some of the most innovative uses of rubber oil seals in industrial applications and highlight their benefits over other types of seals. Whether you're an engineer or just curious about how things work, keep reading to discover more about these fascinating components!

What are Rubber Oil Seals?

Rubber oil seals, also known as shaft seals or lip seals, are essential components of rotating machinery. They consist of an elastomeric sealing lip that is bonded to a metal case and held in place by a spring. The sealing lip contacts the surface of the shaft or bore and prevents the escape of lubricants or contaminants.

These seals come in various sizes and shapes depending on their intended application. Some have additional features like dust lips to protect against debris, while others may incorporate multiple sealing elements for added protection.

One advantage of rubber oil seals over other types such as mechanical face seals is their simplicity and ease of installation. They are typically less expensive than other seal types and can be easily replaced when worn out without requiring extensive disassembly.

In addition to industrial applications, rubber oil seals are also used in automotive engines, transmission systems, pumps, compressors, and many other devices where effective sealing is critical for optimal performance.

How are Rubber Oil Seals Used in Industrial Applications?

Rubber oil seals are important components used in a wide range of industrial applications. These seals help to prevent the leakage of fluids, such as lubricants and hydraulic oils, from machinery and equipment.

One common use of rubber oil seals is in automotive engines. They are used to seal off critical areas such as crankshafts, camshafts, and pistons from leaking oil. This helps ensure that these parts receive proper lubrication while keeping contaminants out.

Another application for rubber oil seals is in hydraulic systems found on heavy-duty equipment like bulldozers and excavators. In these systems, they help prevent leaks by sealing the various hydraulic cylinders throughout the system.

Rubber oil seals can also be found in manufacturing plants where they play an important role in preventing contamination during production processes. For instance, they can be used to seal food processing equipment or chemical reactors.

Rubber oil seals are essential components that provide reliable sealing performance across a variety of industrial applications.

Some Innovative Uses of Rubber Oil Seals

Rubber oil seals have been used for decades in various industrial applications, but with advancements in technology and materials, innovative uses have emerged. One of the most notable is their use in the automotive industry. Rubber oil seals are now an essential component of modern engines, providing a leak-free seal that prevents contamination between engine components.

Another innovative use of rubber oil seals is in the manufacturing of medical devices. Medical equipment requires high precision and must be free of contaminants to ensure patient safety. Rubber oil seals provide a reliable seal that can withstand harsh sterilization processes without degrading or contaminating the device.

In addition to traditional industrial uses such as pumps and motors, rubber oil seals are also being used extensively in renewable energy applications such as wind turbines and solar panels. These industries demand high reliability under extreme operating conditions, making rubber oil seals an ideal choice due to their ability to resist extreme temperatures and harsh environments while maintaining a tight seal.

Rubber oil seals are proving useful in aerospace applications where they play a critical role in ensuring aircraft functions safely at high altitudes and speeds. They help prevent air leaks from occurring which can cause damage to vital systems during flight.

The innovative uses for rubber oil seals continue to expand across various industries as more manufacturers recognize their versatility, durability and reliability under challenging operating conditions.

Why Use Rubber Oil Seals in Industrial Applications?

Rubber oil seals are essential components in industrial machinery and equipment. These seals provide an effective barrier to prevent the leakage of fluids such as oil or grease from within a machine's mechanical systems. The use of rubber oil seals is crucial in preventing contamination of these fluids, which can lead to damage or failure of the machinery.

One major advantage of using rubber oil seals is their ability to withstand extreme temperatures, pressure variations and harsh chemicals that might otherwise damage other materials. This makes them ideal for use in demanding industrial applications where exposure to high temperatures, dust and debris is common.

Another benefit of using rubber oil seals is their long service life. With proper installation and regular maintenance, these seals can last for years without requiring replacement – saving time and money on costly repairs.

Moreover, by ensuring that machines operate with minimal fluid leaks, it promotes safety since there will be no accidents caused by slippery floors while reducing environmental pollution through reduced carbon footprints.

Rubber Oil Seals play an important role in maintaining optimal performance levels for heavy-duty machinery used across different industries over a prolonged period thus they make great investments for any business looking forward towards efficient operations with minimum downtime due to equipment failures.

Conclusion

To sum it up, rubber oil seals have become an essential part of industrial machinery and equipment. These small components play a crucial role in ensuring the efficient functioning of different types of machines and systems.

From preventing leaks to reducing friction, rubber oil seals offer numerous benefits that make them ideal for use in various applications. Moreover, with advancements in technology, engineers and designers are discovering new ways to utilize these seals to improve machine performance and durability.

So if you're looking for a reliable solution to prevent fluid leakage or reduce wear and tear in your machinery, consider using high-quality rubber oil seals. With their versatility and effectiveness, they can help optimize your operations while enhancing safety and overall productivity.

Custom message