Exploring the Functionality of Shaft Oil Seals

Exploring the Functionality of Shaft Oil Seals

Introduction

Shaft oil seals play a crucial role in various industries where efficient sealing is required to prevent leakage of fluids and contaminants. These seals are specifically designed to keep lubricants in and contaminants out of rotating machinery, such as engines, gearboxes, and motors. In this article, we will delve into the functionality of shaft oil seals, understanding their construction, importance, working principle, common applications, and maintenance tips.

Construction of Shaft Oil Seals

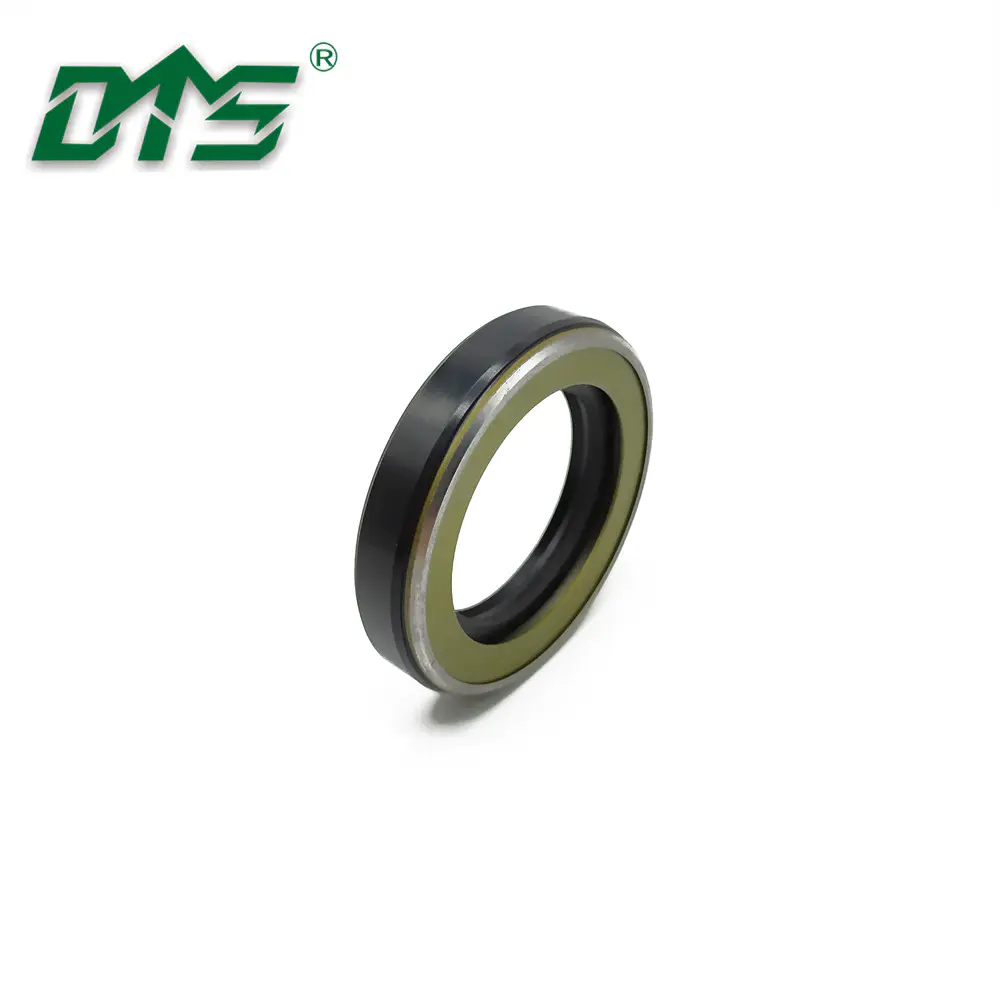

Shaft oil seals are typically composed of three main components: a metal case, a sealing element, and a spring. The metal case forms the outer shell of the seal, providing structural support and protecting the internal components from external damage. Inside the case, the sealing element, made of either rubber or elastomeric material, creates a tight seal against the rotating shaft. The spring, often located within the rubber sealing element, applies constant pressure to ensure a secure seal.

Working Principle

Shaft oil seals function based on the principle of creating a barrier between two regions, one containing lubricating oil and the other exposed to the external environment. The seal prevents oil leakage by forming a tight seal around the rotating shaft while allowing a small film of lubricating oil to form between the shaft and the seal. This thin layer of oil acts as a lubricant, reducing friction and wear, thereby increasing the longevity of the machinery.

Importance of Shaft Oil Seals

Shaft oil seals are vital for maintaining the efficiency and reliability of rotating machinery. Their primary role is to prevent oil leakage, which can have several adverse effects. Leakage not only leads to loss of lubricants but also allows contaminants to enter the machinery, leading to accelerated wear, reduced performance, and potential equipment failure. Additionally, excessive oil leakage can create safety hazards and environmental pollution. Therefore, properly functioning shaft oil seals are crucial for ensuring the longevity and optimal performance of machinery.

Common Applications of Shaft Oil Seals

Shaft oil seals find applications in a wide range of industries, including automotive, manufacturing, aerospace, marine, and more. Some common applications include:

1. Automotive Industry - In vehicles, shaft oil seals are used in engines, transmissions, and differentials to prevent oil leakage and maintain performance.

2. Industrial Machinery - From pumps and compressors to conveyor systems and hydraulic equipment, shaft oil seals play a vital role in preventing fluid leakage and ensuring efficient operation.

3. Aerospace - In aircraft engines and other critical aviation systems, shaft oil seals contribute to the overall reliability and safety of the equipment.

4. Marine Industry - Shaft oil seals are extensively used in marine propulsion systems, preventing saltwater contamination and ensuring the smooth operation of ship engines.

5. HVAC Systems - Heating, ventilation, and air conditioning systems rely on shaft oil seals to maintain efficient energy transfer while preventing refrigerant leakage and contamination.

Maintenance Tips for Shaft Oil Seals

To ensure the longevity and optimal performance of shaft oil seals, regular maintenance is essential. Here are some useful tips to keep in mind:

1. Inspect and replace worn seals: Periodically inspect the seals for signs of wear or damage. If any damage is detected, prompt replacement is necessary to maintain the integrity of the seal.

2. Use compatible lubricants: Ensure that the lubricants used are compatible with the shaft oil seals. Incompatible lubricants can degrade the seals, leading to premature failure.

3. Clean the sealing area: Before replacing a seal, clean the sealing area thoroughly to remove any debris, dirt, or contaminants that could compromise the effectiveness of the new seal.

4. Proper installation: Follow manufacturer guidelines for installing shaft oil seals accurately. Avoid damaging the seals during installation and use appropriate tools to ensure a secure fit.

5. Regular servicing: Include shaft oil seals in your regular equipment servicing schedule. This will help detect any issues early on and prevent major breakdowns due to seal failure.

Conclusion

Shaft oil seals are essential components in various industries to prevent oil leakage and protect machinery from contaminants. Understanding their construction, working principle, and maintenance requirements is crucial for ensuring optimal performance and durability of rotating equipment. By implementing proper maintenance practices and choosing high-quality seals, industries can minimize downtime, improve efficiency, and reduce costly repairs.