Ensuring Maximum Seal Integrity in High-Speed Rotating Rod Applications

Ensuring Maximum Seal Integrity in High-Speed Rotating Rod Applications

Introduction

Sealing is a critical aspect in high-speed rotating rod applications, where maintaining maximum seal integrity is of utmost importance. It becomes even more crucial in industries such as automotive, aerospace, and manufacturing, where rotational speeds are skyrocketing. By employing advanced sealing techniques and technologies, engineers can ensure the flawless performance of these rotating rods, preventing leakages and avoiding costly downtime. In this article, we will delve into the challenges faced in achieving maximum seal integrity and explore various strategies to overcome them.

Understanding the Challenges

1. High Rotational Speeds and Frictional Forces

In high-speed rotating rod applications, the primary challenge lies in the extreme rotational speeds coupled with intense frictional forces. These forces exert tremendous pressure on the seals, leading to wear and tear, ultimately compromising the integrity of the seal. Additionally, the increased centrifugal forces can cause seals to deform, allowing fluid or gas to escape.

2. Thermal Expansion and Contraction

Operating at high speeds generates substantial heat, resulting in thermal expansion and contraction. This phenomenon can cause seals to shift or become misaligned, leading to leakage. The temperature fluctuations also affect the seal material, making it prone to hardening, cracking, or deterioration over time.

3. Vibration and Shock

Another significant challenge is the vibration and shock experienced by rotating rods during operation. These mechanical vibrations exert additional stress on the seals, potentially causing them to lose their sealing capabilities. The constant impact and vibration can eventually lead to seal failure, causing leaks and compromising overall system performance.

4. Contamination and Environmental Factors

High-speed rotating rods are often exposed to harsh environmental conditions, including dust, dirt, moisture, and chemicals. These external factors can infiltrate the sealing system, leading to abrasion, corrosion, or chemical reactions with the seal material. The presence of contaminants and aggressive substances undermines the seal integrity, resulting in potential leaks.

Strategies for Ensuring Maximum Seal Integrity

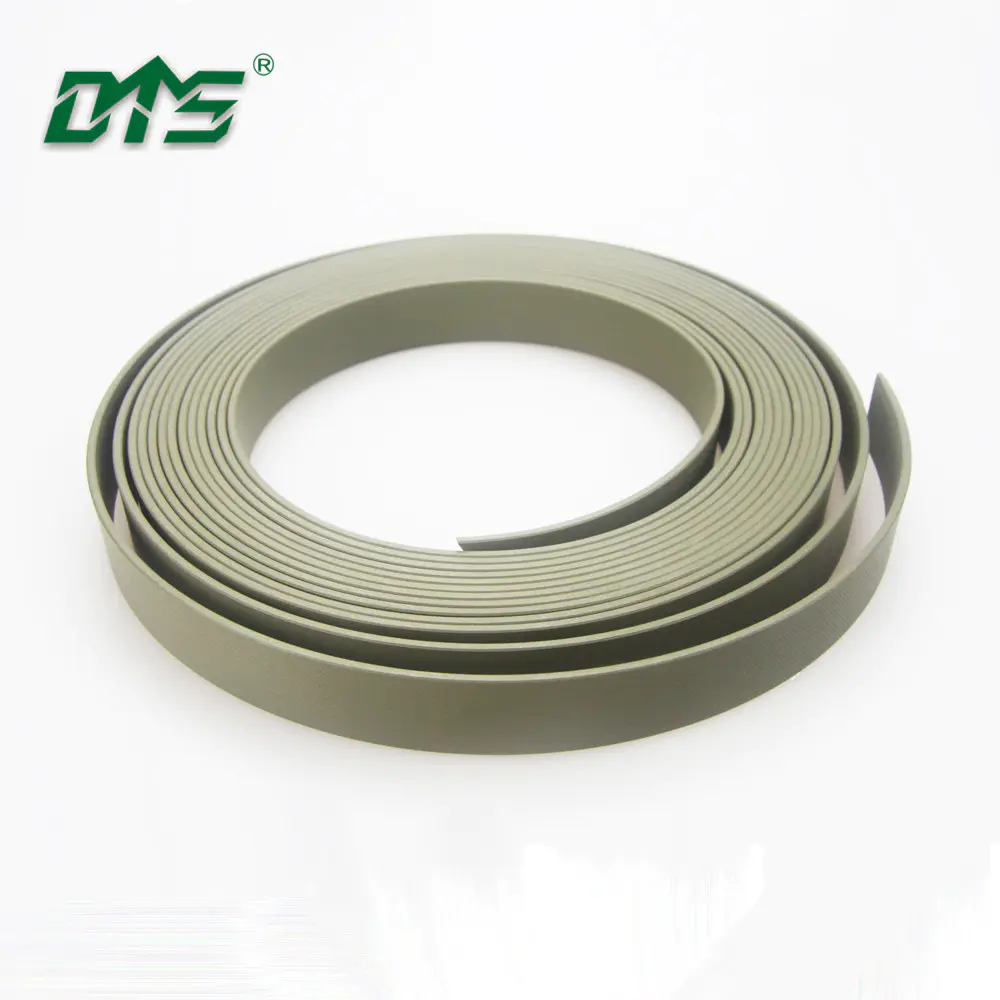

1. Material Selection

Choosing the right seal material is crucial when aiming for maximum seal integrity in high-speed rotating rod applications. The material should possess excellent wear resistance, chemical compatibility, and the ability to withstand high temperatures. Advanced materials like polytetrafluoroethylene (PTFE), silicone, or Viton are commonly used due to their exceptional sealing properties.

2. Design Optimization

Optimizing the seal design is essential to counteract the challenges imposed by high-speed rotation. Engineers can employ various design techniques such as labyrinth seals, double or triple lip seals, or exclusion seals tailored specifically for rotating rod applications. These designs provide enhanced sealing capabilities while minimizing the effects of friction, heat, and vibration.

3. Lubrication and Cooling Systems

Implementing an efficient lubrication and cooling system is vital to maintaining seal integrity. Proper lubrication reduces friction, heat generation, and wear on the seals, extending their lifespan. Cooling systems, such as oil coolers or heat exchangers, help dissipate excess heat, preventing thermal expansion and contraction, and preserving the seal's functionality.

4. Quality Control and Periodic Maintenance

Regular quality control checks and periodic maintenance play a significant role in ensuring maximum seal integrity. Employing inspection techniques such as ultrasonic testing, leak testing, or visual inspections helps detect any seal degradation or fault early on. Regular maintenance allows for timely replacements or repairs, preventing catastrophic seal failures and subsequent downtime.

5. Advanced Seal Technologies

Advancements in seal technologies have greatly contributed to achieving maximum seal integrity in high-speed rotating rod applications. Innovative solutions like self-lubricating seals, magnetic seals, or polymer-based seals offer improved performance and longevity. These technologies address specific challenges such as reducing friction, eliminating leakage paths, or increasing resistance to environmental factors.

Conclusion

Sealing integrity is critically important in high-speed rotating rod applications, ensuring the efficient operation of various industries. Overcoming the challenges posed by rotational speeds, thermal fluctuations, vibration, and environmental factors requires a comprehensive approach. By selecting suitable materials, optimizing designs, implementing lubrication and cooling systems, maintaining periodic inspections, and embracing advanced seal technologies, engineers can guarantee maximum seal integrity. Investing in robust sealing solutions not only minimizes leaks and downtime but also enhances overall system performance and safety.