Advanced Sealing Solutions for Dynamic Hydraulic Applications

Advanced Sealing Solutions for Dynamic Hydraulic Applications

Introduction:

Hydraulic applications involve the transfer of power through the use of pressurized fluids. These applications are commonly found in heavy machinery, industrial equipment, and automotive systems. To ensure the efficient and reliable operation of hydraulic systems, adequate sealing solutions are crucial. In this article, we will discuss some advanced sealing solutions for dynamic hydraulic applications that offer improved performance and durability.

1. The Importance of Sealing Solutions in Dynamic Hydraulic Applications:

Sealing plays a critical role in hydraulic systems as it helps to prevent fluid leakage, contamination, and loss of performance. In dynamic hydraulic applications, where constant movement and high-pressure conditions are present, the selection of appropriate sealing technology becomes even more crucial. Advanced sealing solutions are designed to meet the demanding requirements of dynamic hydraulic systems, providing enhanced reliability and longevity.

2. High-Performance O-Rings:

O-rings are widely used in hydraulic applications due to their versatility and cost-effectiveness. Advanced O-ring materials such as polyurethane, fluorocarbon, and perfluoroelastomer offer improved resistance to wear, temperature, and chemicals, making them suitable for dynamic hydraulic applications. The development of high-performance O-rings allows for better sealing under extreme conditions, minimizing leakage and ensuring system efficiency.

3. Robust Piston Seals:

Piston seals are vital for maintaining the integrity of hydraulic cylinders, preventing fluid bypass and ensuring optimal performance. Advanced piston seal designs, incorporating materials like polytetrafluoroethylene (PTFE) and thermoplastic elastomers (TPE), offer superior wear resistance and excellent sealing capabilities. These innovative seals can withstand high pressures, temperature variations, and dynamic movements, making them ideal for dynamic hydraulic applications.

4. Cutting-Edge Rotary Shaft Seals:

Rotary shaft seals are used to prevent fluid leakage along rotating shafts in hydraulic systems. In dynamic hydraulic applications, where rotational speeds and pressures are high, conventional sealing solutions may fall short. Advanced rotary shaft seals equipped with innovative lip designs and durable materials like polytetrafluoroethylene (PTFE) or fluoroelastomers (FKM) are proven to outperform traditional seals. These seals provide enhanced sealing efficiency, reduced friction, and extended service life, contributing to the overall reliability of the hydraulic system.

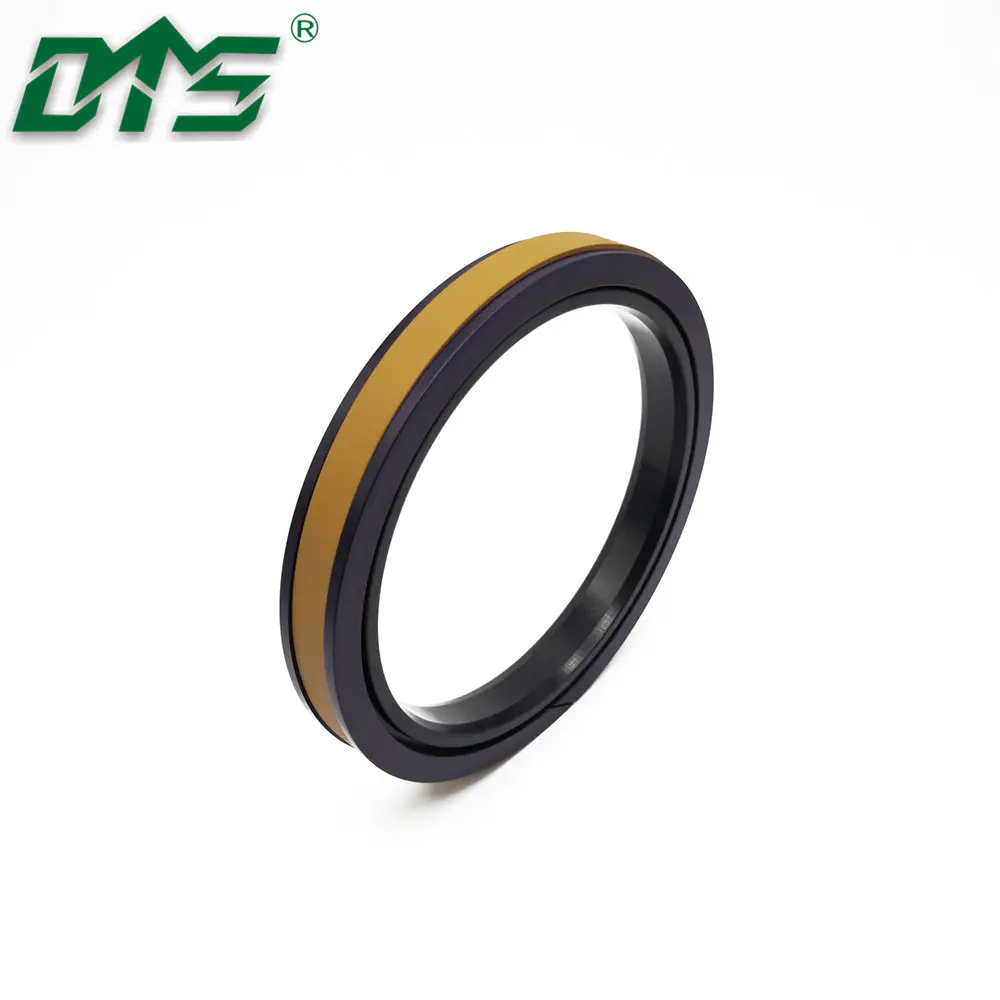

5. Utilizing Advanced Composite Seals:

Dynamic hydraulic applications often require seals that can withstand extreme conditions, such as high temperature, aggressive chemicals, and abrasive media. Advanced composite seals, made from a combination of elastomer, thermoplastic, and reinforcement materials, offer exceptional resistance to wear, extrusion, and compression set. These seals provide an effective solution for challenging hydraulic environments, ensuring reliable sealing performance even in the most demanding applications.

6. The Advantages of Integrated Seal Systems:

Integrated seal systems combine multiple sealing components into a single unit, offering numerous benefits in dynamic hydraulic applications. By integrating various sealing functions, such as sealing, guiding, and retaining, into a compact design, these systems reduce installation complexity, minimize the risk of component mismatch, and improve overall system efficiency. Additionally, integrated seal systems streamline inventory management and simplify maintenance procedures, making them an excellent choice for hydraulic applications that demand reliability and performance.

Conclusion:

In dynamic hydraulic applications, where reliability and efficiency are paramount, advanced sealing solutions play a crucial role. High-performance O-rings, robust piston seals, cutting-edge rotary shaft seals, composite seals, and integrated seal systems offer improved sealing performance, extended service life, and enhanced durability in the face of extreme conditions. By utilizing these advanced sealing solutions, hydraulic systems can operate optimally, ensuring uninterrupted power transfer and minimizing the risk of downtime and costly repairs.