What is rubber seal?

Rubber Seal: A Versatile and Essential Component for Numerous Applications

Introduction

Rubber seals are a crucial yet often overlooked component that plays a significant role in ensuring tight seals and preventing leaks in various mechanical systems. They are widely utilized in industries such as automotive, construction, aerospace, and many others. In this article, we will delve into the world of rubber seals, exploring their composition, types, applications, advantages, and maintenance techniques.

I. What is a Rubber Seal?

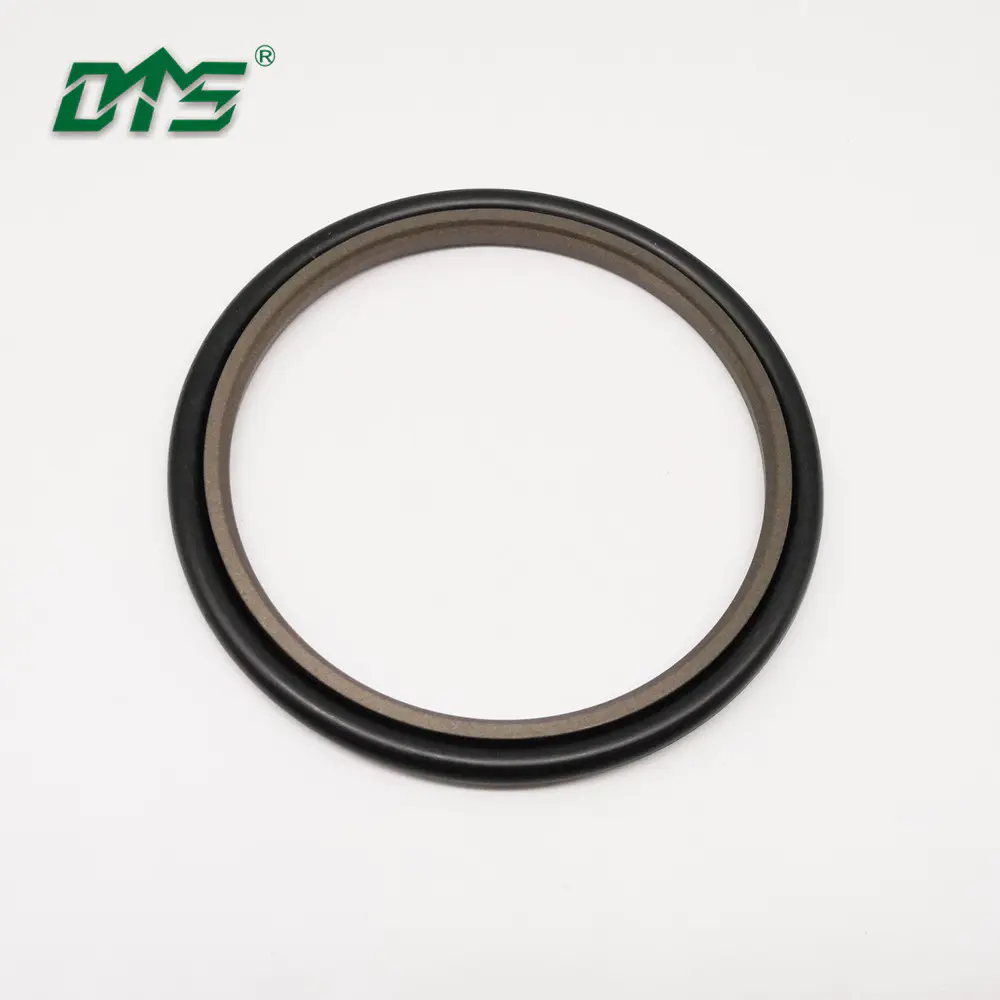

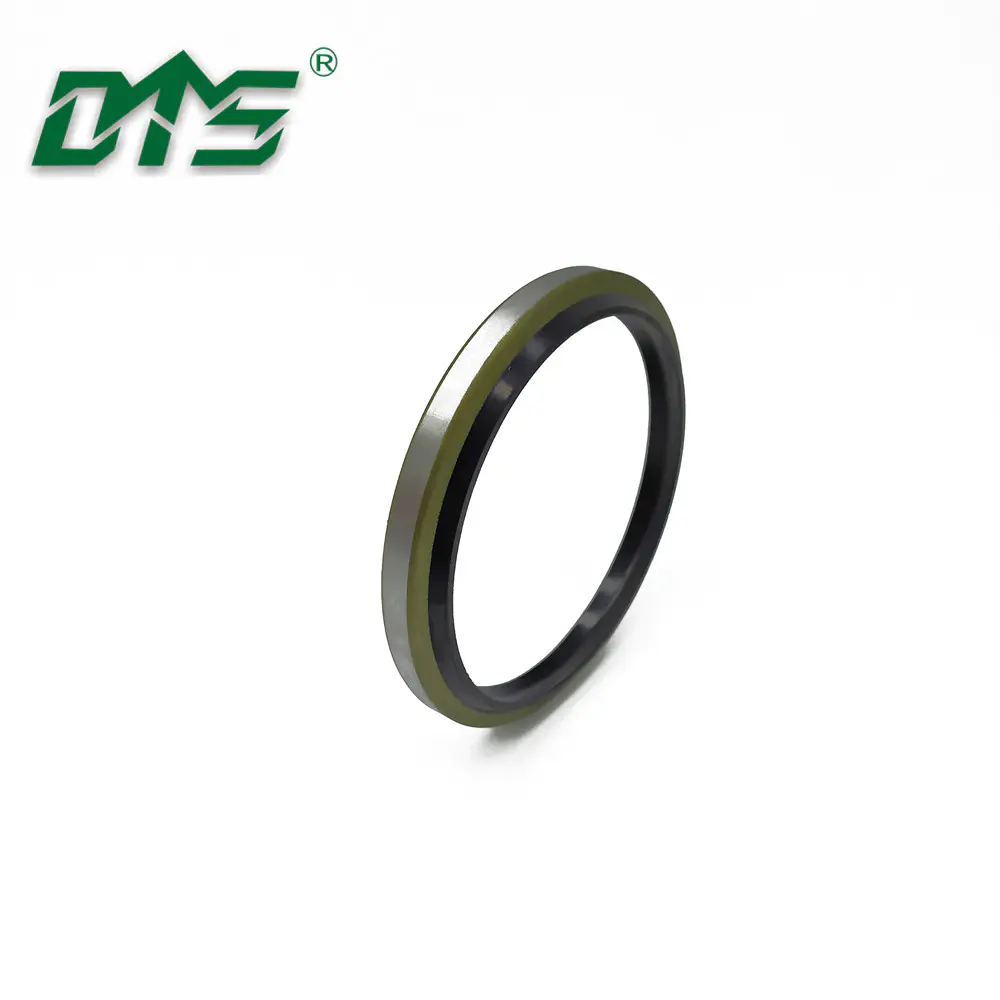

A rubber seal, also known as a gasket or an O-ring, is an elastomeric component typically made from synthetic materials such as neoprene, silicone, or EPDM (Ethylene Propylene Diene Monomer). These seals are designed to fill gaps and provide a secure barrier against the transfer of fluids, gases, dust, and other contaminants between two or more joining surfaces.

II. Types of Rubber Seals

1. O-Rings

O-rings are the most common type of rubber seal, named after their circular shape resembling the letter 'O.' They are widely used in hydraulic systems, pumps, engines, and numerous mechanical assemblies. O-rings come in various sizes and materials to accommodate different temperature ranges and chemical resistances.

2. Sealing Strips

Sealing strips, also known as weatherstrips, are commonly used in buildings and vehicles to prevent air, water, and noise leakage. These flexible strips, often made from EPDM rubber, are installed between doors, windows, hoods, and trunks to ensure a tight seal and enhance energy efficiency.

3. Gaskets

Gaskets are typically flat seals used to create a secure connection between two stationary surfaces, such as flanges or valve covers. They are available in a range of shapes, including square, rectangular, and circular, and are utilized in industries like manufacturing, oil and gas, and plumbing.

4. Diaphragms

Diaphragms are versatile rubber seals that undergo flexing or displacement to regulate the flow of liquids or gases. They commonly find application in pumps, regulators, valves, and pneumatic systems. Made from materials like nitrile rubber or silicone, diaphragms must possess excellent elasticity, durability, and chemical resistance.

5. Boots and Bellows

Boots and bellows are accordion-like rubber structures designed to protect sensitive components from external contaminants, such as dirt, moisture, or debris. They provide flexible covers for components exposed to constant movement, such as driveshafts and steering mechanisms in automotive applications.

III. Applications of Rubber Seals

1. Automotive Industry

Rubber seals are extensively used in the automotive sector to create tight seals in engines, transmissions, brake systems, and other critical areas. They prevent fluid leaks, reduce noise, and contribute to the overall safety and performance of vehicles.

2. Mechanical and Industrial Applications

In mechanical and industrial settings, rubber seals are employed in pumps, compressors, pipelines, and hydraulic systems to maintain pressure, prevent leaks, and ensure efficient operations. They also play a vital role in food processing, pharmaceutical manufacturing, and chemical processing industries where strict hygiene and contamination control are crucial.

3. Aerospace and Marine

The aerospace and marine industries heavily rely on rubber seals for various applications, including aircraft engines, fuel systems, navigation equipment, and shipbuilding. These seals withstand extreme pressures, temperatures, and harsh environmental conditions to ensure the safety and reliability of these critical systems.

4. Construction and Infrastructure

Rubber seals are employed in the construction sector for sealing joints in buildings, bridges, tunnels, and other infrastructure projects. They protect against water infiltration, maintain structural integrity, and enhance energy efficiency.

5. Electrical and Electronics

Rubber seals are indispensable in electrical and electronic devices, serving as insulators and providing protection against moisture, dust, and vibrations. They find application in electrical enclosures, connectors, cables, and switches, contributing to the longevity and functionality of these components.

IV. Advantages of Rubber Seals

1. Excellent Sealing Properties

Rubber seals offer outstanding sealing capabilities, ensuring tight connections and preventing leakage of fluids, gases, and particles. Their elasticity enables them to conform to irregular surfaces, providing a reliable seal even under varying pressures.

2. Wide Temperature Range

Rubber seals can withstand a wide range of temperatures, from extremely cold environments to high-temperature applications. Specialized formulations are available for extreme conditions, making rubber seals suitable for diverse industries.

3. Chemical Resistance

Many rubber seal materials exhibit excellent resistance to various chemicals, oils, fuels, and solvents. This property ensures the longevity and performance of seals in environments where exposure to corrosive substances is prevalent.

4. Durable and Long-lasting

Rubber seals are known for their durability, strength, and resistance to wear and tear. Properly maintained seals can endure years of service under demanding conditions, reducing the need for frequent replacements.

V. Maintenance of Rubber Seals

To maximize the lifespan and effectiveness of rubber seals, regular maintenance is crucial. Here are a few maintenance tips:

1. Inspection

Regularly inspect rubber seals for any signs of wear, damage, or degradation. Replace seals that show visible cracks, deformities, or offer inadequate sealing capabilities.

2. Lubrication

Apply lubricants compatible with the rubber seal material to reduce friction and prevent drying or cracking. Lubrication also aids in easy installation and removal of seals.

3. Cleaning

Keep rubber seals clean by removing dirt, debris, or any substance that might deteriorate the material. Use mild detergent solutions or recommended cleaning agents for this purpose.

4. Storage

Store spare rubber seals in a cool, dry place away from direct sunlight and chemicals that might degrade the material. Ensure proper packaging to prevent deformation or damage during storage.

Conclusion

Rubber seals are essential components used across various industries to ensure leak-free operations, protect against environmental conditions, and enhance the efficiency and longevity of mechanical systems. By understanding the types, applications, advantages, and maintenance techniques associated with rubber seals, one can make informed decisions and select the most suitable seal for specific requirements.