What are national oil seals?

Introduction:

National oil seals are an integral part of various mechanical systems, from automobiles to industrial machinery. These seals play a crucial role in preventing leaks and maintaining proper lubrication within these systems. In this article, we will delve into the world of national oil seals, exploring their significance, types, functions, and applications. So, let's dive in!

I. The Importance of National Oil Seals

National oil seals are designed to effectively seal the gaps between stationary and moving parts in mechanical systems. Their primary purpose is to retain lubricants within the mechanical systems while preventing contaminants from entering. By creating a barrier against leaks, national oil seals ensure smooth operation, extend the lifespan of critical components, and minimize costly downtime.

II. Types of National Oil Seals

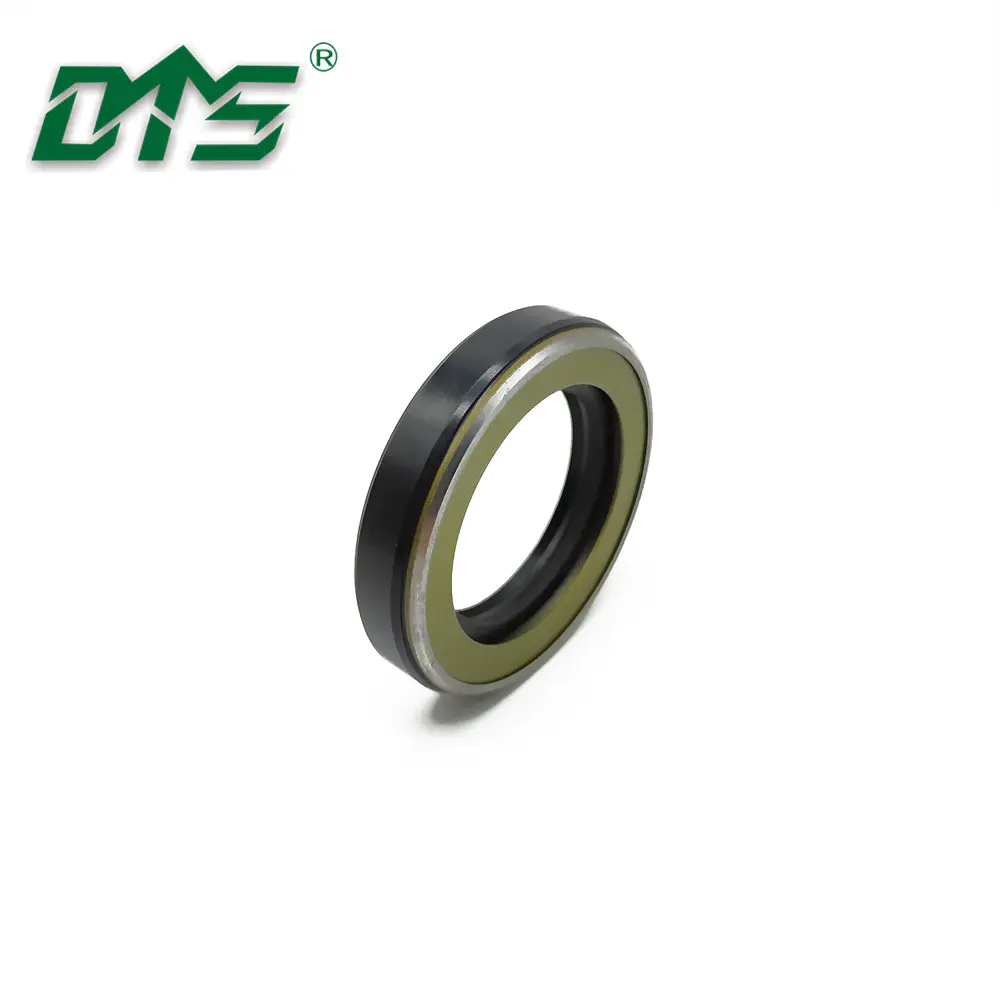

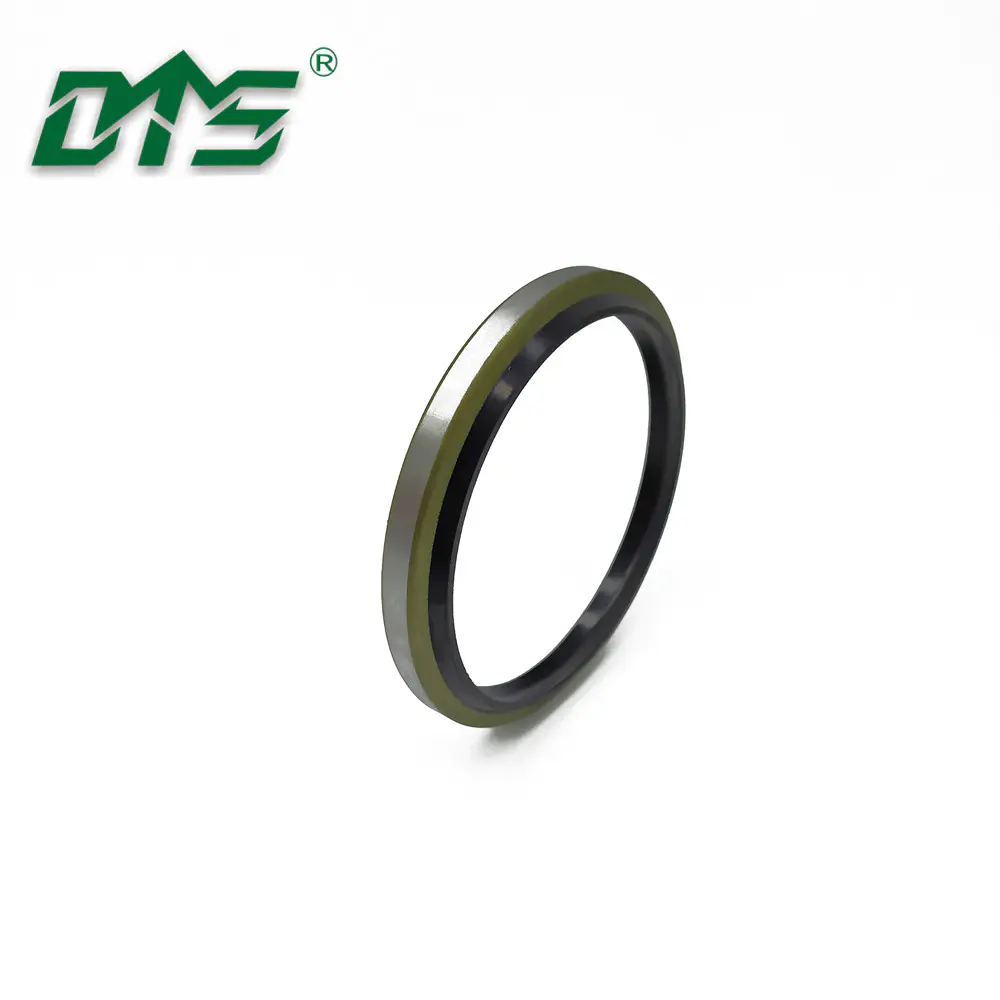

1. Lip Seals:

The most common type of national oil seal, lip seals, feature a flexible lip that comes in direct contact with the rotating or reciprocating shaft. This lip is typically made of rubber or elastomeric materials, ensuring effective sealing and accommodating radial movement of the shaft.

2. V-Seals:

V-seals, also known as axial shaft seals, offer excellent sealing characteristics for machinery with rotary shafts that experience high speeds and varying pressures. These seals are designed to operate in both directions and work efficiently in extreme temperatures, making them ideal for demanding applications.

3. Mechanical Seals:

Unlike lip and V-seals, mechanical seals are employed in applications where high pressure, hazardous fluids, or extreme temperatures are involved. These seals consist of two flat sealing surfaces held together by spring tension. This design ensures a tight and dynamic sealing capability, even in challenging conditions.

4. Cassette Seals:

Cassette seals are commonly used in heavy-duty applications like construction and mining machinery. These seals feature a unique design that combines a sealing element and protective cover into a single unit, ensuring superior performance even in harsh environments.

5. Hydraulic Seals:

Hydraulic systems rely on hydraulic seals to prevent fluid leakage and maintain hydraulic pressure. These seals play a crucial role in applications where cylinders and pistons are involved, such as in hydraulic brakes, shocks, and lifts. They are designed to withstand high pressure and offer exceptional resistance to wear and tear.

III. Functions of National Oil Seals

National oil seals serve multiple functions within mechanical systems, including:

1. Leakage Prevention:

By creating a tight seal between stationary and moving parts, national oil seals effectively prevent fluid leakage, ensuring the system's proper functioning.

2. Contaminant Exclusion:

These seals act as a barrier against contaminants like dust, dirt, water, and other harmful substances, preserving the integrity of the lubricating fluid and preventing premature wear and damage to critical components.

3. Lubrication Retention:

National oil seals play a vital role in retaining lubricants within mechanical systems. Proper lubrication is essential for reducing friction, heat, and wear, thus maximizing the system's efficiency and lifespan.

4. Vibration and Noise Reduction:

By minimizing metal-to-metal contact and adequately cushioning moving parts, national oil seals help reduce vibration and noise, ensuring smooth and quiet operation.

5. Shaft Protection:

Oil seals protect the shaft from corrosion, rust, and other damage caused by exposure to external elements. This protection helps maintain the overall performance and longevity of the mechanical system.

IV. Applications of National Oil Seals

National oil seals find extensive usage across various industries and applications, including:

1. Automotive:

In the automotive industry, oil seals are utilized in engines, transmissions, differential units, and wheel hubs to prevent oil leakage, maintain lubrication, and protect critical components from contaminants.

2. Industrial Machinery:

From heavy-duty manufacturing equipment to small handheld tools, national oil seals are essential for sealing rotating or reciprocating shafts in industrial machinery, such as pumps, generators, conveyor systems, and compressors.

3. Aerospace:

In the aerospace sector, oil seals are critical for sealing aircraft engines, landing gear systems, hydraulic systems, and other essential components, ensuring reliable and safe operation.

4. Marine:

National oil seals play a vital role in sealing engine shafts, propeller shafts, and other rotating components in marine vessels, preventing leakage and protecting against the corrosive effects of seawater.

5. Agriculture:

In agricultural machinery, oil seals are used in tractors, combine harvesters, and other farm equipment to keep the lubrication intact and provide reliable sealing against harsh environmental conditions.

Conclusion:

National oil seals are indispensable components that provide crucial sealing functions in various mechanical systems. Without these seals, maintaining proper lubrication, preventing leakage, and protecting critical components would be challenging. With their diverse types and applications, national oil seals ensure the efficient operation and longevity of machinery in industries ranging from automotive to aerospace. Whether it's reducing friction and noise or keeping contaminants at bay, these seals are vital contributors to the performance and reliability of mechanical systems.