Innovative Uses for Bonded Seals in Automotive and Aerospace Engineering

Possible article:

Innovative Uses for Bonded Seals in Automotive and Aerospace Engineering

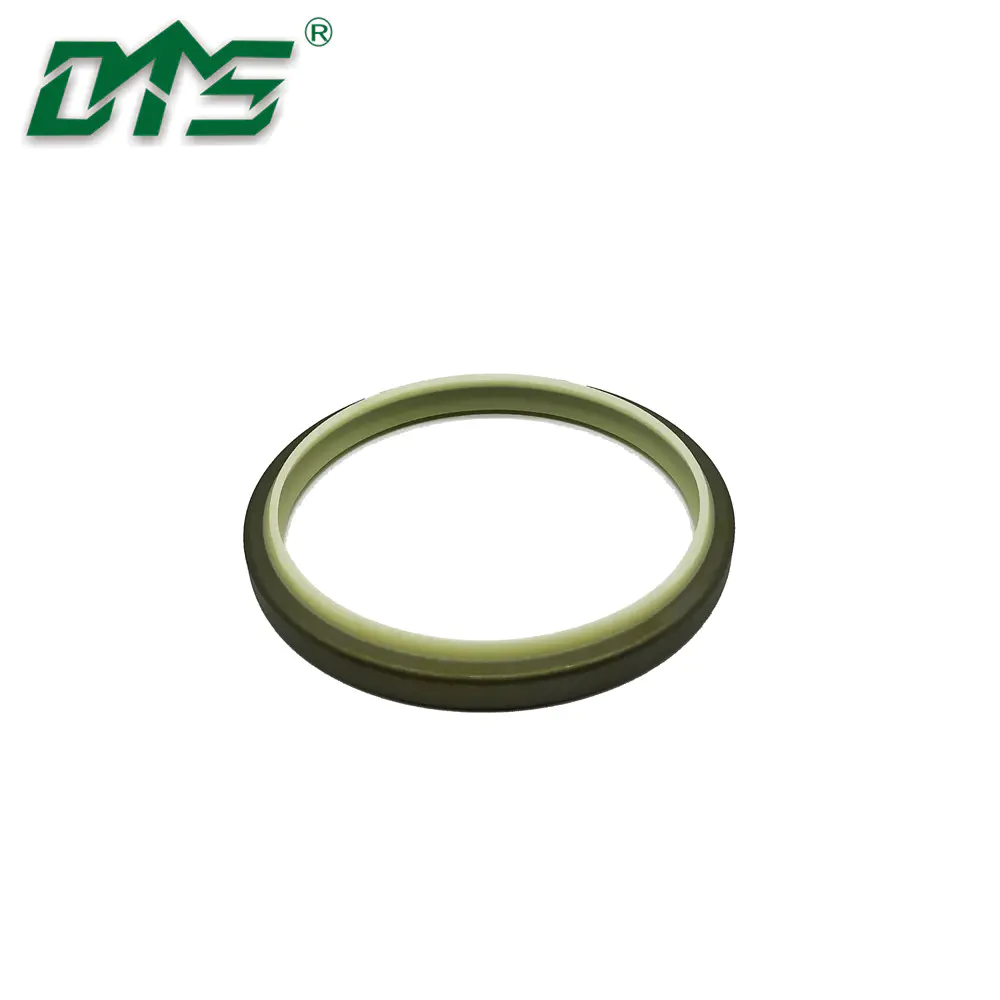

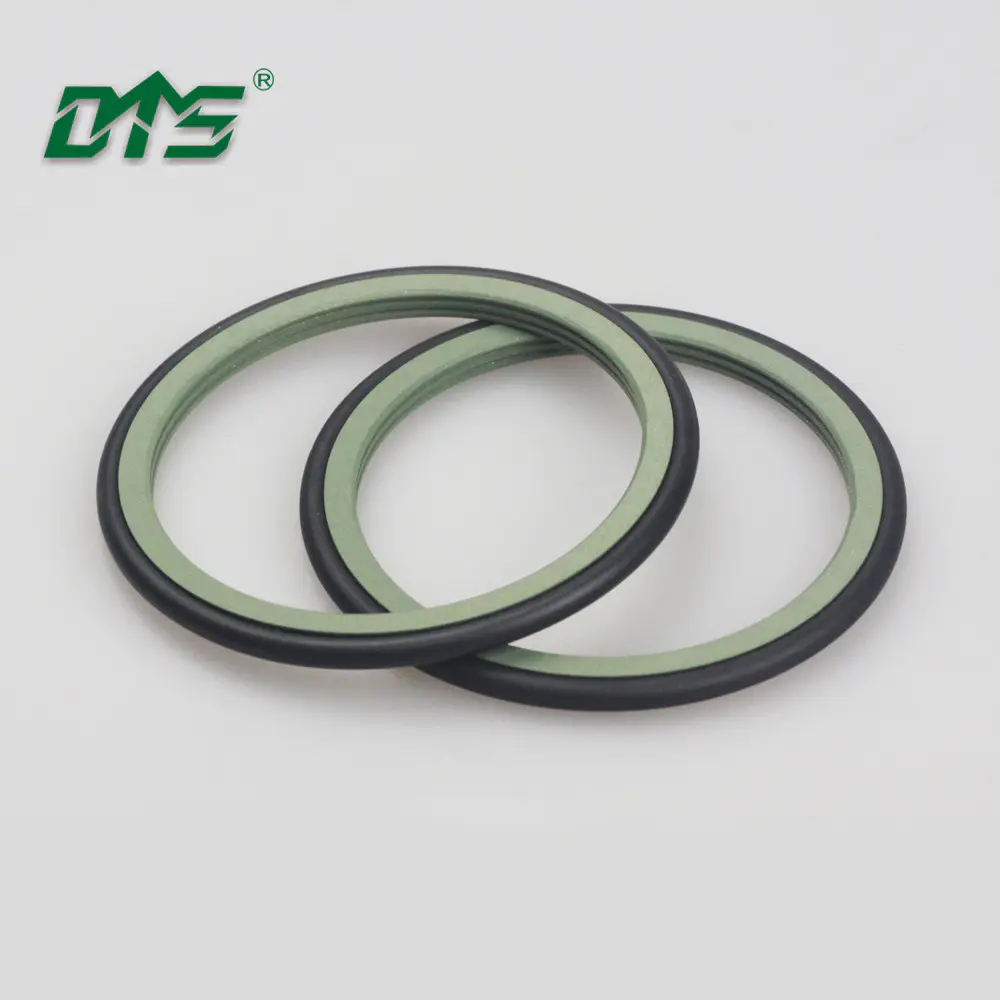

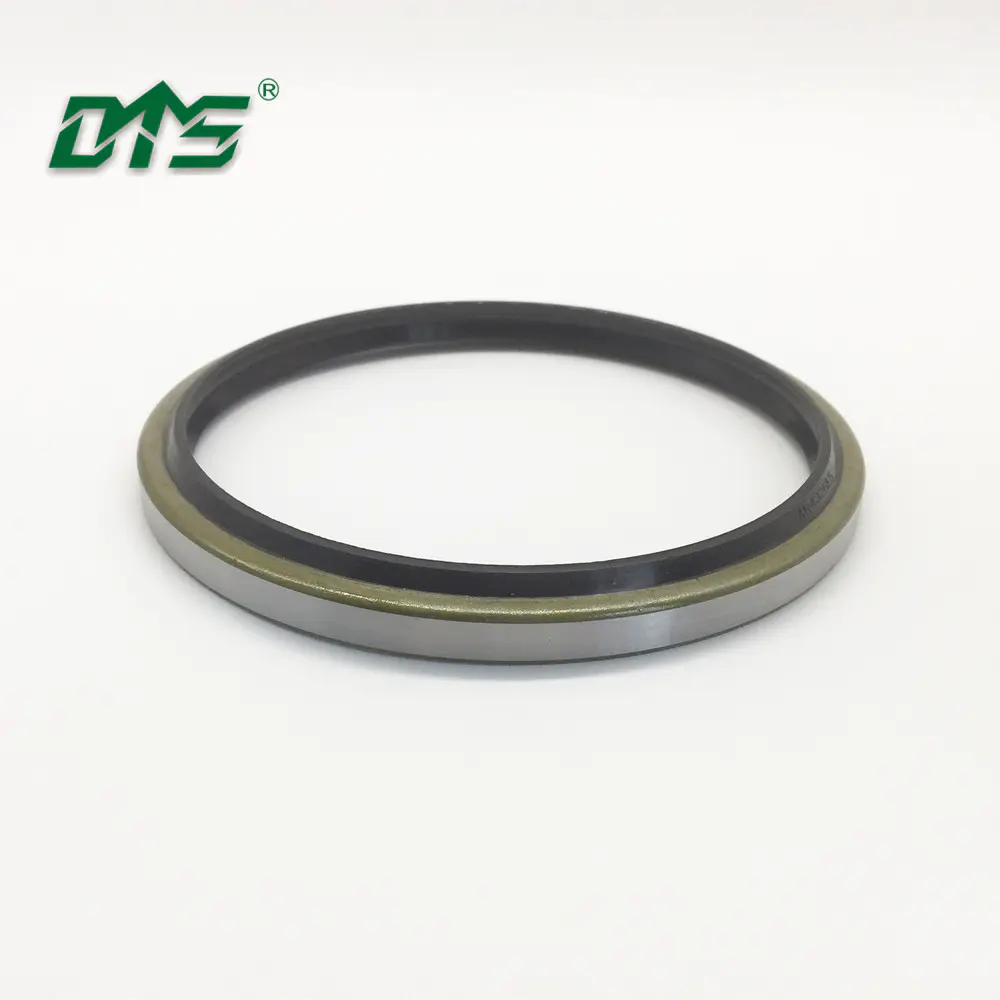

Bonded seals are compact and reliable sealing solutions that combine a rubber seal and a metal washer into a single unit. They provide excellent resistance to high pressure, temperature, and chemical exposure, as well as vibration and torque. Bonded seals are widely used in various industries, such as automotive, aerospace, hydraulic, pneumatic, and plumbing, to seal fluid and gas systems, prevent leaks and contamination, and improve performance and safety. This article explores some innovative uses for bonded seals in automotive and aerospace engineering, and how they can benefit different applications.

Subtitles:

- Sealing Brake Systems with Bonded Seals

- Bonded Seals for Fuel Injectors

- Bonded Seals in Landing Gear Systems

- Bonded Seals for Hydraulic Actuators

- Advantages of Using Bonded Seals in Extreme Environments

Sealing Brake Systems with Bonded Seals

Brake systems are critical components of vehicles and aircraft, as they enable the driver or the pilot to slow down or stop the motion by applying friction forces between the brake pads and the discs or drums. However, brake systems also generate heat and pressure, which can cause the brake fluid to expand and leak if the seals are not adequate. Bonded seals can provide a reliable and cost-effective solution for sealing brake systems, especially in applications that require high pressure or high temperature resistance, such as racing cars, heavy-duty trucks, or military aircraft.

Bonded seals can be used to seal various brake system components, such as calipers, master cylinders, wheel cylinders, brake hoses, and brake boosters. The bonded seal consists of a metal washer with a raised rim and a rubber seal bonded to the inside of the rim. The metal washer is designed to fit snugly into the brake system housing, while the rubber seal compresses against the mating surface to form a tight seal. The raised rim of the washer prevents the rubber from extruding or deforming under pressure, and also provides additional support and stability to the seal.

Bonded Seals for Fuel Injectors

Fuel injectors are essential parts of modern engines, as they deliver precise amounts of fuel to the combustion chamber based on the engine demand and the driver input. Fuel injectors operate under high pressure and temperature, and they require tight sealing to prevent leakage, clogging, or contamination. Bonded seals can be used to seal different types of fuel injectors, such as electronic, mechanical, or common-rail, and can improve their performance and reliability.

Bonded seals can seal the fuel injector sealing surface, the fuel inlet or outlet ports, or the fuel rail connections. The bonded seal provides a long-lasting and leak-proof seal that resists the effects of fuel, oil, and heat. Bonded seals also eliminate the need for conventional O-rings, which can harden, shrink, or become brittle over time, leading to leaks and failures. By using bonded seals, fuel injectors can operate with higher accuracy, lower emissions, and longer lifespan.

Bonded Seals in Landing Gear Systems

Landing gear systems are crucial parts of aircraft, as they enable the aircraft to take off, fly, and land safely on different surfaces and conditions. Landing gear systems consist of many components, such as struts, shock absorbers, wheels, brakes, and steering systems, that need to be sealed from external elements and maintain proper lubrication and pressure. Bonded seals can be used in landing gear systems to provide a high-performance and low-maintenance sealing solution.

Bonded seals can be used in landing gear systems to seal the hydraulic cylinders, the brake and steering actuators, the gear doors, and the wheel bearings. The bonded seal provides a stable and secure sealing interface that can withstand high pressure, temperature, and turbulence. Bonded seals also require less space and weight than other seal types, which can help reduce the overall weight and cost of the aircraft. Moreover, bonded seals can be easily installed and replaced, which can enhance the maintainability and reliability of the landing gear system.

Bonded Seals for Hydraulic Actuators

Hydraulic actuators are essential components of many systems in automotive and aerospace engineering, such as power steering, power brakes, suspension, and flight control. Hydraulic actuators convert the hydraulic pressure into mechanical motion that can move different parts and perform various tasks. However, hydraulic actuators also require tight sealing to prevent leaks, contamination, or malfunction. Bonded seals can be used in hydraulic actuators to provide efficient and effective sealing performance.

Bonded seals can be used in hydraulic actuators to seal the hydraulic cylinder, the piston, and the hydraulic connections. The bonded seal ensures that the hydraulic fluid cannot escape from the system and that external elements cannot enter the system, which can compromise the performance and safety of the system. Bonded seals are compatible with different types of hydraulic fluids, such as mineral oil, synthetic oil, or water-based fluids. Bonded seals can also reduce the risk of seal twisting, rolling, or extruding, which can affect the hydraulic force and motion.

Advantages of Using Bonded Seals in Extreme Environments

Bonded seals offer several advantages over other sealing solutions in extreme environments, such as high altitude, low temperature, high humidity, or corrosive environments. Bonded seals can resist the effects of temperature cycling, ozone, UV radiation, and chemical exposure, which can compromise the sealing performance and durability of other seal types. Bonded seals also provide excellent resistance to shock, vibration, and torque, which can occur in rugged or dynamic environments.

Moreover, bonded seals can be designed and customized to meet specific requirements of different applications, such as size, shape, material, or performance. Bonded seals can also be applied in both static and dynamic sealing applications, where other seal types may not work well. Overall, bonded seals can provide a versatile, reliable, and efficient sealing solution for various automotive and aerospace engineering applications, and help improve the overall quality and safety of these industries.