All You Need to Know About O-Rings: A Comprehensive Guide

All You Need to Know About O-Rings: A Comprehensive Guide

O-rings are important sealing devices used in various industries such as aerospace, automotive, and plumbing. These small, circular rubber rings help prevent liquid or gas from escaping or entering a system. They come in different sizes, materials, and grades depending on their usage. In this comprehensive guide, we will discuss everything you need to know about O-rings.

1. What are O-rings?

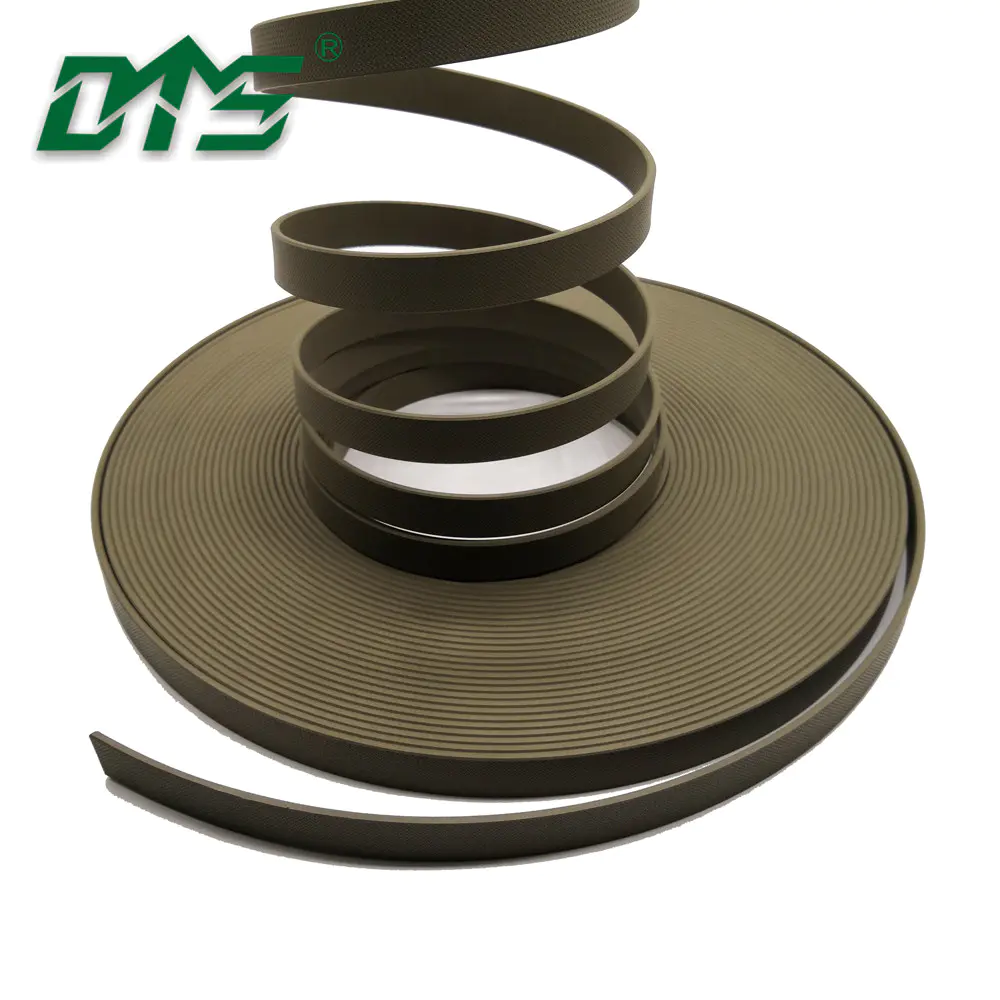

O-rings are round-shaped, elastomeric seals with a circular cross-section. They are made of different materials such as silicone, nitrile rubber, neoprene, Viton, and EPDM. O-rings are used to create a tight seal in pipes, cylinders, fittings, valves, and other mechanical applications to prevent fluids from escaping or entering the system.

2. How do O-rings work?

O-rings work by creating a seal between two mating surfaces. When installed, the O-ring is compressed between the two surfaces, which forces it to fill the gap between them. The O-ring then acts as a barrier that prevents the fluid or gas from escaping or entering the system. The elastic properties of the O-ring allow it to maintain its sealing properties even with changes in temperature, pressure, and vibration.

3. What are the different types of O-rings?

There are different types of O-rings depending on their application, material, and size. Some of the common O-ring types are:

a. Silicone O-rings: These are made of silicone rubber, a material that is resistant to extreme temperatures and chemicals. Silicone O-rings are ideal for use in high-temperature applications such as in automobiles, medical devices, and food processing.

b. Nitrile O-rings: These are made of nitrile rubber, a material that is resistant to oil, grease, and other petroleum-based fluids. Nitrile O-rings are commonly used in hydraulic systems, fuel systems, and automotive applications.

c. Viton O-rings: These are made of fluorocarbon rubber, a material that is resistant to chemicals, acids, and high temperatures. Viton O-rings are ideal for use in aerospace, chemical processing, and oil and gas industries.

d. Neoprene O-rings: These are made of neoprene rubber, a material that is known for its resistance to abrasion, ozone, and weathering. Neoprene O-rings are commonly used in water treatment, marine, and mining applications.

4. How to choose the right O-ring?

Choosing the right O-ring for your application is crucial in ensuring its optimal performance. When selecting an O-ring, you need to consider the following factors:

a. Material: The material of the O-ring should be compatible with the fluid or gas that it will come in contact with. For example, if the system has oil or grease, a nitrile O-ring would be the best choice.

b. Temperature range: The temperature range of the O-ring should match the operating conditions of the system. If the system operates at high temperatures, choose an O-ring that can withstand the heat.

c. Pressure rating: The O-ring should be able to tolerate the pressure of the system. The pressure rating of the O-ring is usually indicated in the manufacturer’s specification.

d. Size: The size of the O-ring should be compatible with the size of the fittings, valves, or cylinders that it will be used with.

5. How to install and maintain O-rings?

Proper installation and maintenance of O-rings are essential in maintaining their sealing properties. Here’s how to install and maintain O-rings:

a. Installation: Before installing an O-ring, make sure that it is compatible with the system and the mating surfaces. Clean the surfaces thoroughly to remove any dirt or debris. Apply a lubricant to the O-ring to aid in installation. Make sure that the O-ring is not twisted or pinched during installation.

b. Maintenance: Regular inspection and replacement of O-rings are necessary to prevent leaks and system failure. Check the O-ring for signs of wear, cracks, or damage. Replace the O-ring if it shows any signs of wear and tear. Lubricate the O-ring regularly to prevent dryness and cracking.

In conclusion, O-rings are vital components in various mechanical systems, from simple household plumbing to complex aerospace applications. Choosing the right O-ring and maintaining it properly will help ensure the integrity of the system and prevent costly repairs. By following the guidelines in this comprehensive guide, you can make the most out of your O-ring and keep your mechanical system running smoothly.