Scraper Seals: Essential Components for Contaminant Exclusion in Industrial Machinery

1. Introduction to Scraper Seals: Enhancing Performance and Efficiency in Industrial Machinery

2. Understanding Contaminant Exclusion: The Importance of Scraper Seals

3. Types of Scraper Seals: Choosing the Right Solution for Industrial Applications

4. Installation and Maintenance of Scraper Seals: Ensuring Longevity and Optimal Performance

5. Advancements in Scraper Seal Technology: Innovations for Future Industrial Applications

---

Introduction to Scraper Seals: Enhancing Performance and Efficiency in Industrial Machinery

In the vast realm of industrial machinery, achieving optimal performance and efficiency is crucial for maintaining smooth operations. Unfortunately, the presence of contaminants poses a significant threat to the functionality and longevity of various moving parts within these machines. Scraper seals have emerged as essential components for contaminant exclusion, enabling industrial machinery to operate reliably even in challenging environments. This article delves into the importance of scraper seals, their types, installation, maintenance, and the latest advancements in their technology.

Understanding Contaminant Exclusion: The Importance of Scraper Seals

Contaminants such as dust, dirt, debris, moisture, and abrasive particles can infiltrate the sensitive components of industrial machinery, leading to equipment failure, reduced efficiency, and costly repairs. Scraper seals act as protective barriers, shielding crucial machine parts from contaminants. These seals ensure that rotating shafts, cylinders, and other elements remain free from external pollutants, maintaining optimal performance and extending the lifespan of the machinery.

Types of Scraper Seals: Choosing the Right Solution for Industrial Applications

1. Wiper Scraper Seals:

Wiper scraper seals are commonly used to remove debris and liquids from the surfaces of moving parts, enhancing the efficient functioning of industrial machinery. These seals consist of a low-friction lip that scrapes off contaminants as the machinery operates, preventing their ingress into critical components. Wiper scraper seals are suitable for applications such as hydraulic cylinders, piston rods, and rotating shafts.

2. Exclusion Scraper Seals:

Exclusion scraper seals are specifically designed to exclude contaminants from entering internal machine components, ensuring their protection from harmful substances. These seals employ a lip that creates a barrier to repel debris and liquid particles, effectively sealing the system. Exclusion scraper seals find application in various machinery including pumps, motors, gearboxes, and rotary actuators.

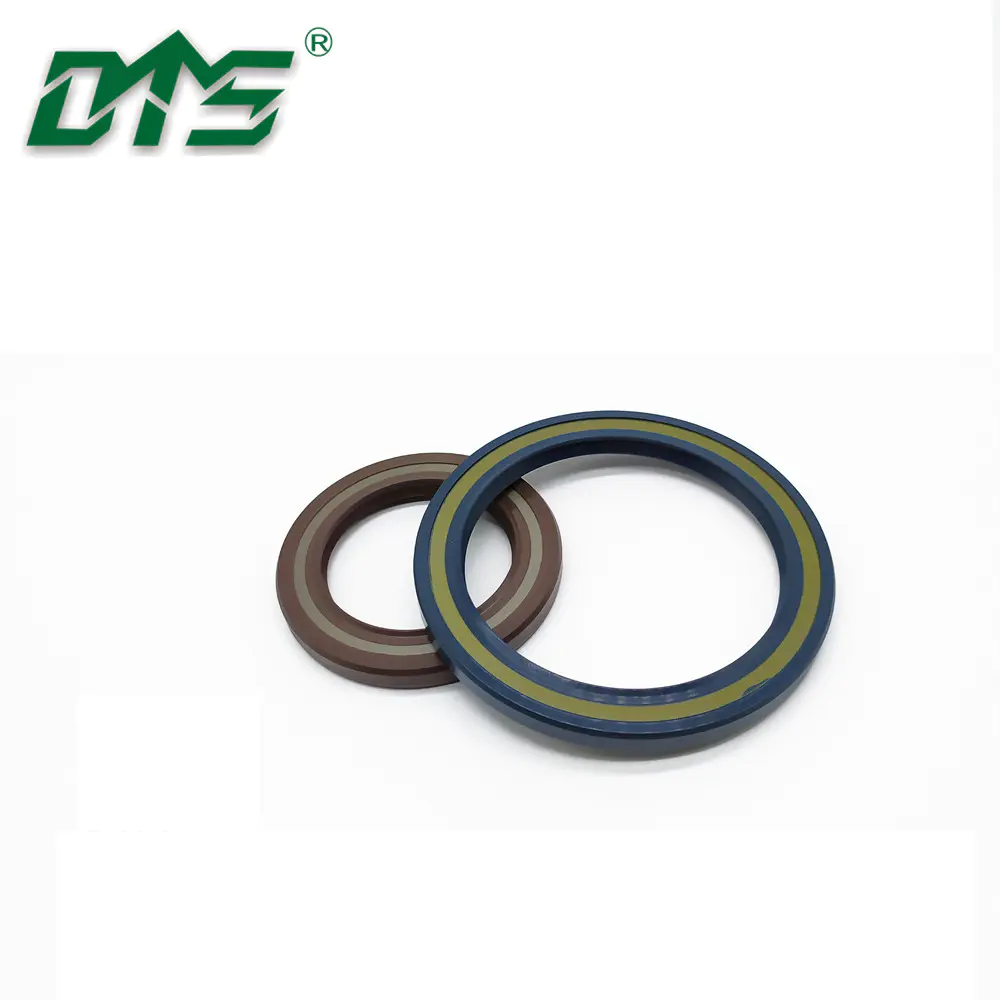

3. Cassette Scraper Seals:

Cassette scraper seals are versatile solutions that offer comprehensive contaminant exclusion. These seals consist of multiple sealing lips working in tandem to prevent the entry of debris, moisture, and other pollutants. Cassette scraper seals provide an increased level of protection against harsh operating conditions and are commonly used in a wide range of industrial applications, including heavy-duty equipment and machinery functioning in extreme environments.

Installation and Maintenance of Scraper Seals: Ensuring Longevity and Optimal Performance

Proper installation and regular maintenance of scraper seals are essential to ensure their longevity and optimal performance. Here are some crucial considerations:

1. Correct Seal Selection:

Choosing the right type and size of scraper seal for a specific industrial application is the first step towards effective contaminant exclusion. Working closely with seal manufacturers or suppliers can help in determining the most suitable seal based on the machinery's operating conditions, dimensions, and environmental factors.

2. Precision Installation:

Scraper seals should be installed accurately and securely to function optimally. Cleanliness is crucial during installation to prevent any debris or dirt from compromising the seal's performance. Following manufacturer guidelines, using appropriate tools, and ensuring proper alignment are essential for successful installation.

3. Regular Inspection:

Regularly inspecting scraper seals for signs of wear, damage, or leakage is vital for early detection of potential issues. Timely replacement of worn or damaged seals can prevent contamination-related failures and maintain the efficiency of industrial machinery.

4. Lubrication Requirements:

Some scraper seals may require lubrication to facilitate smooth movement and efficient operation. Understanding the specific lubrication requirements recommended by the seal manufacturer is essential to prevent seal failure and maintain optimal performance.

Advancements in Scraper Seal Technology: Innovations for Future Industrial Applications

As technology continues to evolve, scraper seal manufacturers are actively developing innovative solutions to meet the changing needs of industrial machinery. Some notable advancements include:

1. Enhanced Material Durability:

Novel materials with improved wear resistance, high-temperature tolerance, and superior sealing properties are being used in the production of scraper seals. These materials offer increased durability and extended service life, ensuring reliable contaminant exclusion in demanding industrial environments.

2. Customized Sealing Solutions:

With advancements in manufacturing techniques, scraper seals can now be customized to fit specific machinery requirements precisely. Tailored seals offer improved sealing efficiency, reduced friction, and enhanced resistance to different types of contaminants.

3. Integrated Monitoring Systems:

Some modern scraper seals come equipped with integrated monitoring systems that provide real-time insights into their performance. These systems can detect early signs of seal failure or leakage, enabling timely maintenance and preventing costly breakdowns.

4. Environmentally Friendly Seals:

Seal manufacturers are developing eco-friendly alternatives by incorporating recyclable and sustainable materials into their products. These environmentally conscious seals aim to reduce waste and environmental impact, aligning with the growing focus on sustainability in industrial practices.

5. Seals for High-Speed Applications:

In response to the increasing demand for high-speed rotating machinery, scraper seal technology has advanced to meet these specific requirements. Special seals designed to withstand high speeds while maintaining efficient sealing performance have been introduced, ensuring smooth operations and extended equipment lifespan.

Conclusion

Scraper seals play a vital role in maintaining the performance, efficiency, and reliability of industrial machinery by excluding contaminants. Through various types of scraper seals, including wiper seals, exclusion seals, and cassette seals, industrial applications can benefit from improved protection against harmful particles. Proper installation, regular maintenance, and advancements in scraper seal technology contribute to the longevity and optimal functioning of industrial machinery, ensuring uninterrupted operations and minimizing downtime. As the industrial sector continues to evolve, scraper seal manufacturers will continue to innovate, providing increasingly effective solutions tailored to the challenges of modern machinery.