Rod Seal Testing and Validation: Key Considerations for Performance Assurance

Rod Seal Testing and Validation: Key Considerations for Performance Assurance

Introduction

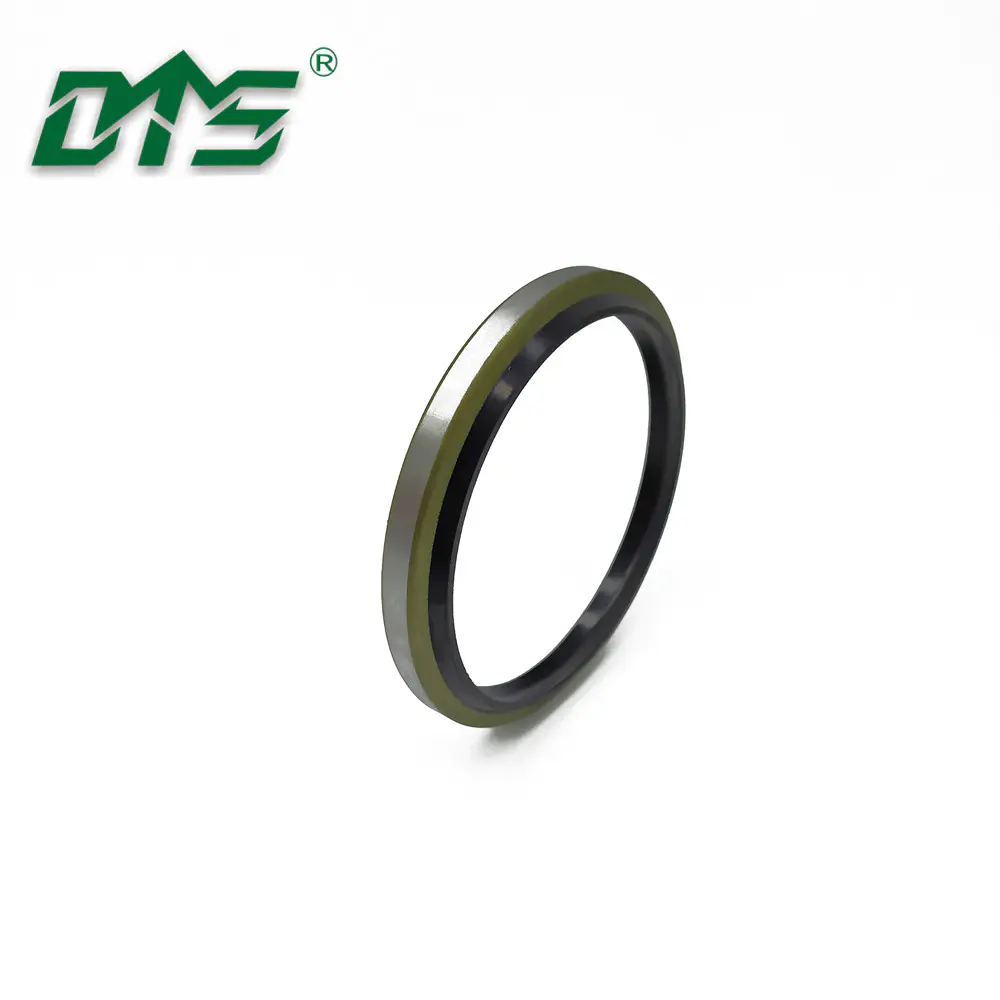

Rod seals play a crucial role in hydraulic and pneumatic systems. They prevent fluid leakage and contamination, ensuring the efficiency and longevity of the system. To ensure optimal performance, it is important to perform rigorous testing and validation of rod seals. In this article, we will discuss the key considerations for rod seal testing and validation to ensure performance assurance.

1. Understanding the Importance of Rod Seal Testing

Rod seals are subjected to extreme pressures, temperatures, and dynamic movements within hydraulic and pneumatic systems. They are exposed to various environmental conditions that can impact their performance. Testing rod seals enables manufacturers to evaluate their durability, effectiveness, and overall performance under different operating conditions.

2. Choosing the Right Testing Equipment

To accurately assess the performance of rod seals, it is essential to choose the right testing equipment. There are several types of tests that can be conducted, including leakage testing, endurance testing, and material compatibility testing. The equipment selected should be capable of replicating the operating conditions that the rod seal will encounter in its application.

3. Leakage Testing

Leakage is one of the primary concerns when it comes to rod seals. A leaky seal can compromise the overall efficiency of the system and lead to contamination. Leakage testing involves subjecting the rod seal to different pressure differentials and measuring the leakage rate. This testing helps determine the sealing effectiveness of the seal and ensures that it meets the required performance standards.

4. Endurance Testing

Endurance testing is crucial to evaluate the durability and longevity of rod seals. This testing involves subjecting the seal to continuous cycles of pressure, temperature, and dynamic movements. The purpose is to simulate the real-world operating conditions and assess how the seal performs over an extended period. Endurance testing helps identify any potential issues or weaknesses in the seal design.

5. Material Compatibility Testing

Rod seals are available in a range of materials, including rubber, polyurethane, and PTFE. Material compatibility testing is important to ensure that the seal material is compatible with the fluid and operating conditions. The seal should be resistant to the fluid being used and must maintain its physical properties over time. Material compatibility testing helps prevent premature seal failure and ensures long-term performance.

6. Environmental Testing

Rod seals are exposed to various environmental factors, such as temperature variations, humidity, and contaminants. Environmental testing is necessary to evaluate how the seal performs under different environmental conditions. This testing helps determine the seal's ability to withstand temperature extremes, resist degradation from UV exposure, and withstand exposure to harsh chemicals.

7. Validation through Real-World Applications

While laboratory testing is crucial, it is equally important to validate the performance of rod seals through real-world applications. Real-world testing provides valuable insights into how the seal performs in actual operating conditions. Manufacturers often collaborate with end-users to install prototypes of the seal in their systems to gather data on performance and make necessary improvements.

Conclusion

Rod seal testing and validation are essential to ensure performance assurance and reliability in hydraulic and pneumatic systems. By choosing the right testing equipment, conducting leakage and endurance testing, evaluating material compatibility, and considering environmental factors, manufacturers can develop rod seals that meet high-performance standards. Validation through real-world applications further strengthens the confidence in the seal's performance. Through thorough testing and validation, manufacturers can assure the efficiency and longevity of rod seals, contributing to the overall success of hydraulic and pneumatic systems.