Preventing Contamination with Advanced Rod Seal Solutions in Aerospace Systems

Preventing Contamination with Advanced Rod Seal Solutions in Aerospace Systems

Introduction

The aerospace industry is characterized by its rigorous demands for reliability and safety. The performance of critical components, such as rod seals, plays a vital role in preventing contamination and ensuring the efficient operation of aerospace systems. This article delves into the significance of advanced rod seal solutions and the tremendous impact they have on safeguarding aerospace systems from contamination.

Understanding the Role of Rod Seals

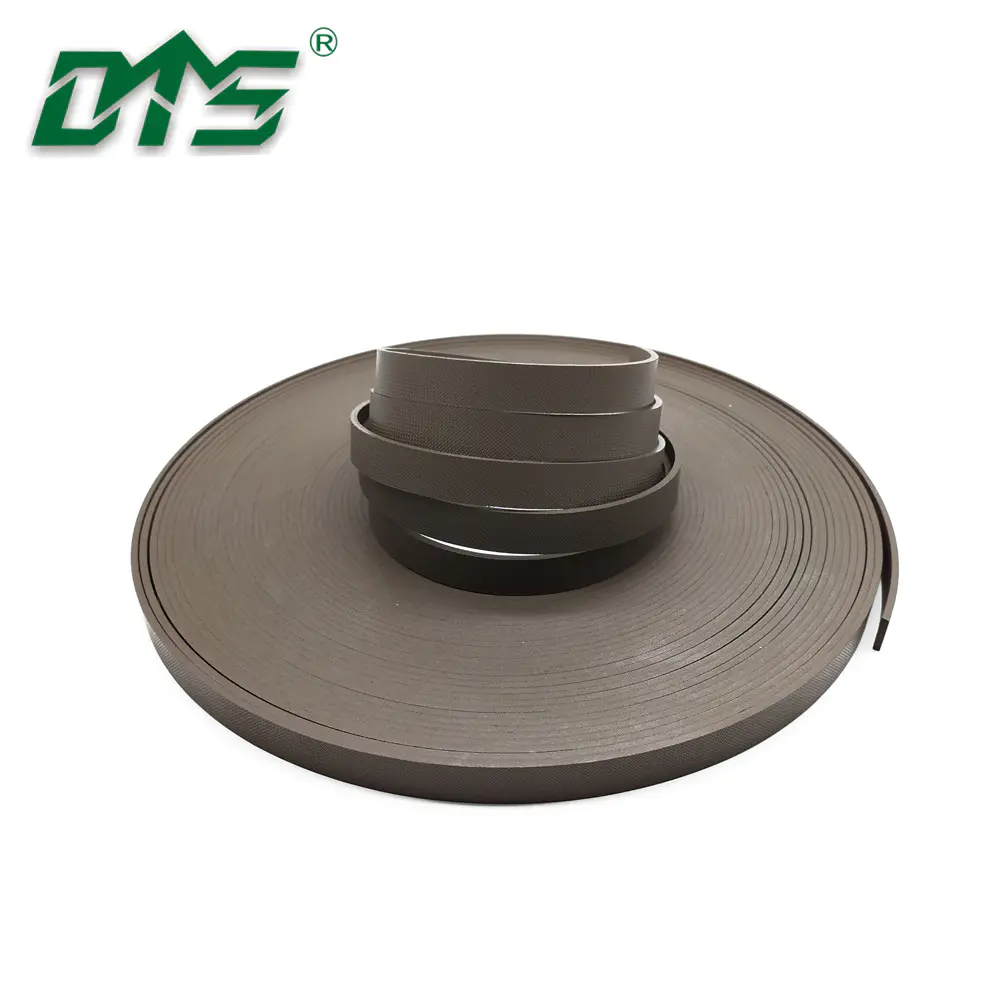

Rod seals are essential components in hydraulic and pneumatic systems, especially in aerospace applications. They are designed to prevent leakage of fluid and contaminant ingress along the axis of a piston or a rod. Rod seals act as critical barriers, ensuring a tight seal between the reciprocating parts and the housing. Their effectiveness directly affects the overall efficiency and reliability of aerospace systems.

Significance of Preventing Contamination in Aerospace Systems

Contaminants in aerospace systems can lead to catastrophic failures, compromising the safety of aircraft and spacecraft. Contamination can include particles, debris, moisture, and other harmful substances that hinder proper system functionality. Preventing contamination is vital for maintaining the integrity of critical components in aerospace systems, avoiding system malfunctions, and ensuring safe operations.

1. Sealing Technology Advancements

With advancements in sealing technology, aerospace engineers can now rely on advanced rod seal solutions that offer superior sealing capabilities and resistance to contamination. These advanced seals are designed to maintain their integrity even under extreme operating conditions, such as high pressures and temperatures. Their ability to withstand these challenging environments while effectively sealing off contaminants is crucial in aerospace applications.

2. Materials with High Resistance

The choice of materials for rod seals is of utmost importance in preventing contamination. Sealing materials with high resistance to chemicals, extreme temperatures, and wear are essential to ensure optimal performance. Advanced elastomers, such as FKM (fluorocarbon rubber), are widely used in aerospace rod seals due to their exceptional resistance to a broad range of fluids and contaminants. These materials provide enhanced durability, reducing maintenance costs and improving the reliability of aerospace systems.

3. Customized Solutions for Specific Aerospace Requirements

Aerospace systems often have unique requirements that demand tailored rod seal solutions. Advanced seal manufacturers specialize in providing custom-designed rod seals to meet specific aerospace needs. These customized solutions take into account factors such as system pressure, temperature, operating speed, and the type of fluid being sealed. By utilizing precisely engineered seal designs, aerospace systems can achieve optimal sealing performance, minimizing the risk of contamination.

4. Testing and Validation Processes

To ensure the effectiveness of rod seal solutions in preventing contamination, rigorous testing and validation processes are conducted. Seal manufacturers subject their products to various tests, including pressure tests, temperature cycling, and exposure to different fluids. These tests simulate real-world operating conditions and verify the seal's performance in preventing leakage and contamination. The testing and validation processes play a crucial role in certifying the reliability and safety of advanced rod seals in aerospace systems.

5. Maintenance and Servicing Considerations

Aerospace systems undergo regular maintenance and servicing to ensure their continued safe operation. During these maintenance procedures, the condition of rod seals is carefully inspected to identify any signs of wear, deterioration, or contamination. Faulty or damaged seals are replaced to maintain the integrity of the system and prevent potential failures. The implementation of advanced rod seal solutions simplifies maintenance procedures, as their high resistance to contamination extends their service life, reducing the frequency of replacements and associated downtime.

Conclusion

In the aerospace industry, preventing contamination is of paramount importance for ensuring system reliability and safety. Advanced rod seal solutions play a critical role in sealing off contaminants that could otherwise lead to failures and malfunctions. The continuous advancements in sealing technology, material selection, customized solutions, testing, and maintenance procedures all contribute to the enhanced performance of rod seals in aerospace systems. By harnessing these advanced solutions, the aerospace industry can significantly mitigate the risk of contamination and continue pushing the boundaries of aviation and space exploration.