Maximizing Uptime with Robust Rod Seals in Offshore Drilling Equipment

Maximizing Uptime with Robust Rod Seals in Offshore Drilling Equipment

Introduction:

Offshore drilling is an essential part of the oil and gas industry, providing access to valuable resources beneath the ocean floor. However, drilling operations in harsh offshore environments are often confronted with numerous challenges that can lead to downtime and decreased productivity. One critical aspect that can significantly impact uptime is the performance of rod seals in drilling equipment. In this article, we will explore the importance of robust rod seals and how they contribute to maximizing uptime in offshore drilling operations.

1. The Role of Rod Seals in Offshore Drilling Equipment:

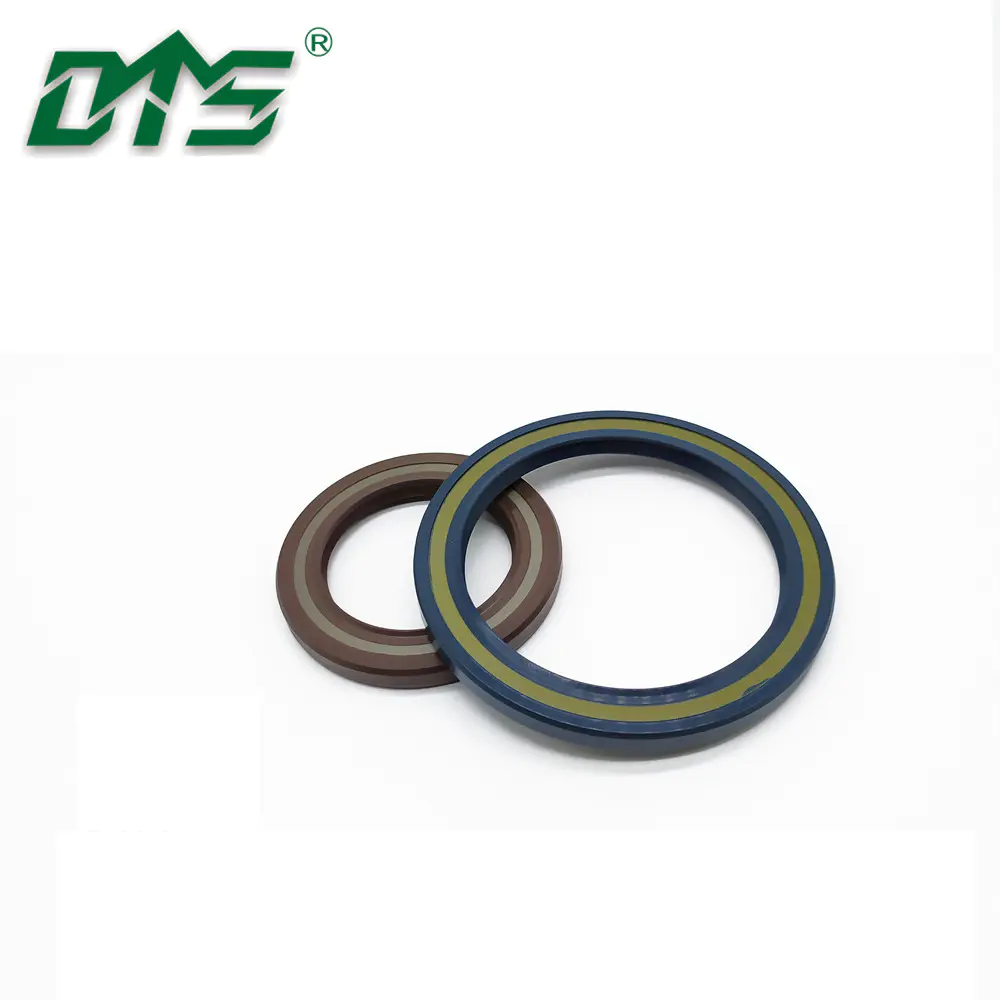

Rod seals play a vital role in preventing leakage of hydraulic fluids and contaminants while maintaining pressure and ensuring optimal performance of hydraulic cylinders in offshore drilling equipment. These seals are subjected to extreme pressure, temperatures, and abrasive substances present in the drilling environment. Therefore, it is crucial to use robust rod seals that can withstand such harsh conditions and provide long-lasting reliability.

2. Challenges in Offshore Environments:

Offshore drilling equipment faces a multitude of challenges that can negatively impact the performance of rod seals and lead to downtime. Corrosive saltwater, high-pressure conditions, abrasive particles, and the constant exposure to UV radiation are just a few of the factors that stress rod seals in offshore operations. Moreover, the need for extended operational periods without maintenance or repair further emphasizes the importance of using robust rod seals capable of withstanding these challenges.

3. Benefits of Robust Rod Seals:

a) Enhanced Durability: Robust rod seals are designed to withstand extreme conditions and provide extended service life in offshore drilling equipment. With superior material properties and advanced manufacturing techniques, these seals can resist wear, corrosion, and extrusion, thus minimizing the risk of seal failure and reducing downtime due to maintenance.

b) Reduced Leakage: Leakage of hydraulic fluids can lead to unnecessary downtime and increased costs. Robust rod seals are engineered to provide excellent sealing performance even under high-pressure conditions, effectively minimizing or eliminating leakage issues. This ensures continuous operation and enhanced productivity in offshore drilling operations.

c) Protection Against Contaminants: In offshore drilling environments, the presence of abrasive particles and other contaminants represents a significant challenge for rod seals. Robust seals are specifically designed to provide a tight barrier against external elements, preventing contaminants from entering the hydraulic system. By protecting the cylinder and its components, rod seals contribute to extended equipment lifespan and minimized maintenance requirements.

4. Advanced Materials for Robust Rod Seals:

The use of advanced materials is critical for the development of robust rod seals in offshore drilling equipment. Various high-performance materials, such as polyurethane, fluoroelastomers, and PTFE (polytetrafluoroethylene), offer exceptional resistance to extreme temperatures, chemicals, and wear. These materials enable rod seals to maintain their integrity and effectiveness in the harsh operating conditions experienced in offshore drilling operations.

5. Design Considerations for Optimal Performance:

a) Customizable Solutions: Offshore drilling equipment often requires specialized rod seals due to unique design requirements and operating conditions. Manufacturers of robust rod seals offer customizable solutions that can be tailored to specific equipment needs, ensuring optimal performance and maximum uptime.

b) Seal Geometry: The geometry of rod seals plays a crucial role in their sealing performance. Designs that include anti-extrusion features, such as back-up rings or sealing lips with appropriate profiles, help prevent seal damage and maintain effective sealing under high-pressure conditions. It is essential to select rod seals with the right geometry to ensure reliable performance in offshore drilling equipment.

c) Installation and Maintenance: Proper installation and regular maintenance are essential for maximizing the lifespan and performance of robust rod seals. Following manufacturer guidelines and employing trained personnel for installation and maintenance tasks can significantly contribute to uptime optimization and minimize the risk of seal failure.

Conclusion:

Robust rod seals are crucial components in offshore drilling equipment, contributing to maximized uptime and enhanced productivity. With the ability to withstand extreme conditions, prevent leakage, and protect against contaminants, these seals play a vital role in prolonging the lifespan of hydraulic cylinders and minimizing downtime. By using advanced materials and considering design optimization, offshore drilling operators can ensure reliable sealing performance and ultimately achieve effective and efficient drilling operations.