Advanced Sealing Solutions for Dynamic Scraper Applications

Advanced Sealing Solutions for Dynamic Scraper Applications

Introduction to Dynamic Scraper Applications

Dynamic scraper applications play a vital role in numerous industrial sectors. These applications involve the use of scraper systems to remove impurities, contaminants, or excess materials from surfaces. Some common examples of dynamic scraper applications include conveyor systems, material handling equipment, cleaning machinery, and agricultural tools.

Challenges in Sealing Dynamic Scrapers

Ensuring effective sealing in dynamic scraper applications presents several challenges. The repetitive motion of the scraper systems combined with environmental factors such as moisture, dust, and abrasive materials can cause accelerated wear and tear on the sealing components. This leads to decreased efficiency, increased maintenance requirements, and potential failure of the entire system.

One major issue is the constant need for readjustment or replacement of seals due to wear. Traditional sealing solutions often struggle to withstand the demanding conditions of dynamic scrapers, resulting in frequent downtime and increased costs for businesses.

Advanced Sealing Solutions for Dynamic Scraper Applications

To address these challenges, advanced sealing solutions have been developed specifically for dynamic scraper applications. These solutions utilize innovative materials and designs to enhance the performance, durability, and longevity of seals in demanding environments.

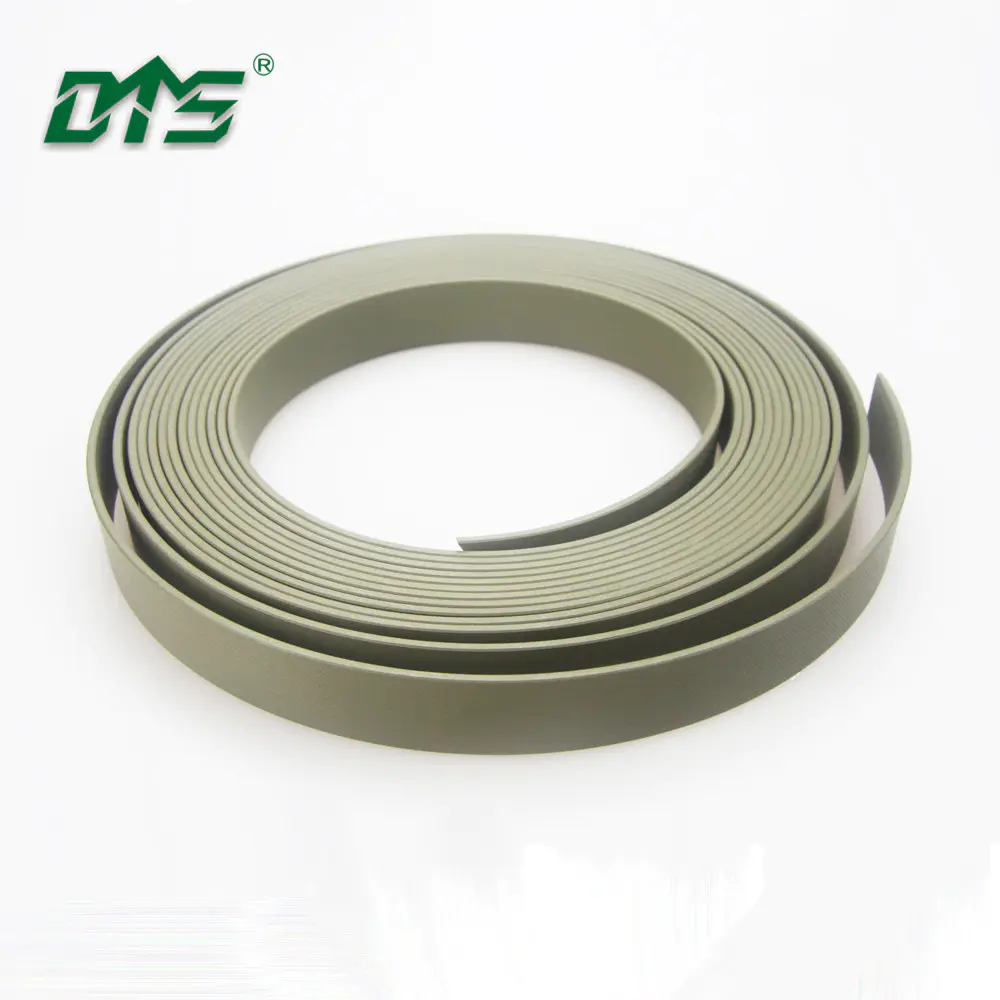

One such solution is the use of high-performance polymer seals. These seals are engineered to withstand the repetitive motion, abrasion, and exposure to harsh substances commonly encountered in dynamic scraper applications. The advanced materials used in these seals provide superior resistance to wear, chemical degradation, and extreme temperatures, ensuring reliable performance over extended periods.

Another advanced sealing solution is the incorporation of self-lubricating properties. Seals that possess self-lubricating capabilities reduce friction and minimize wear between moving components, enhancing the overall efficiency of the dynamic scraper system. The self-lubricating feature reduces the need for frequent maintenance, improves operational reliability, and extends the service life of the seals.

Furthermore, advanced sealing solutions often integrate unique geometries and designs tailored to the specific requirements of dynamic scraper applications. This customization ensures optimal sealing performance, preventing the ingress of contaminants and maintaining effective operation of the scraper systems. The use of advanced sealing solutions minimizes leakages, reduces downtime, and improves overall operational efficiency.

Benefits and Applications of Advanced Sealing Solutions

The adoption of advanced sealing solutions in dynamic scraper applications provides several benefits to industries. Enhanced seal performance and durability lead to increased system uptime, resulting in improved productivity and profitability. Reduced maintenance requirements result in cost savings and minimized operational disruptions.

Industries such as mining, agriculture, construction, and manufacturing heavily rely on dynamic scraper applications. Implementing advanced sealing solutions in these sectors ensures efficient material handling, clean surfaces, and higher-quality end products. By preventing impurities from contaminating a production line or process, advanced sealing solutions contribute to the overall safety and integrity of the operation.

Future Perspective: Innovations in Dynamic Scraper Sealing

The continuous pursuit of innovation in the field of dynamic scraper sealing has led to ongoing research and development efforts. As technology evolves, new sealing materials, designs, and manufacturing techniques are being explored to further improve sealing performance.

The integration of intelligent sensors and predictive maintenance technologies is also an emerging trend in dynamic scraper sealing. Real-time monitoring of seal condition and performance enables businesses to proactively address potential issues, minimize downtime, and optimize maintenance schedules.

Another area of future focus involves sustainability and environmental considerations in sealing solutions. Researchers are actively exploring eco-friendly materials and processes that reduce the environmental footprint of sealing products, aligning with the growing demand for more sustainable industrial practices.

In conclusion, advanced sealing solutions for dynamic scraper applications have revolutionized the efficiency and reliability of these systems. By utilizing high-performance polymers, self-lubricating properties, and customized designs, these sealing solutions provide enhanced performance, durability, and minimizing downtime. The benefits provided by advanced sealing solutions have resulted in increased productivity, cost savings, and improved overall operation in various industries. With ongoing innovations and a focus on sustainability, the future of dynamic scraper sealing holds promising opportunities for further advancements and improvements in sealing technology.