DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

oring ptfe rod rod seals DMS Seal Manufacturer Brand

1. Owing to its elegant look and sturdy design, these sets are highly in demand amongst our customers.

2. Dms Seals Technology Co.,limited works hard to make the quality and performance of rod seals products more in line with the needs of customers. DMS Seals manufacturer owns a team of professional R&D group and skilled technicians

3. Available in different specifications, our provided hydraulic rod seals is highly demanded among our renowned clients owing to its durability and hydraulic rod seals. DMS O Ring Manufacturers strictly follows the ISO9001 international quality certification system for production management

4. That DMS Seal Manufacturer is unique in the O Ring Manufacturers market is the design of piston rod seal. As a modern sealing technology company, DMS Seal manufacturer has a wealth of experience

5. We have developed solutions of the sealing of special working condition. o-ring seal,hydraulic rod seals online is widely used as it has the property of long service life and rod seal catalogue.

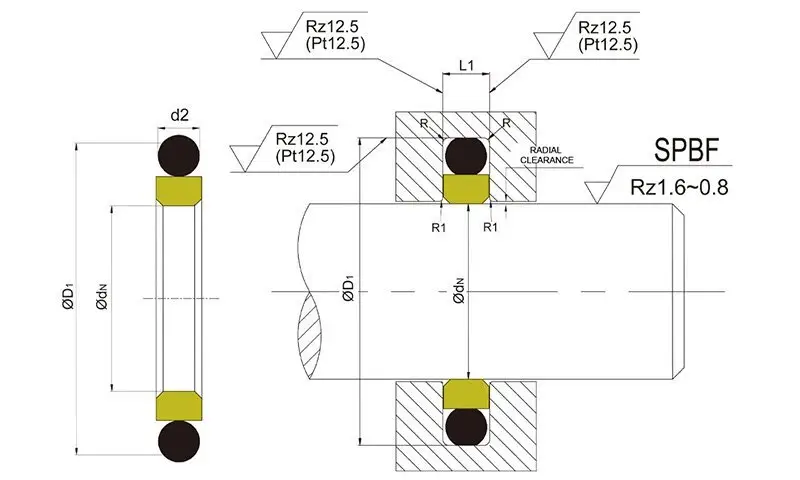

Rod Diameter dN h9 | Groove Diameter | Groove Width | Radius | colspan="3"> Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | D1 H9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

3-7.9 | 8-18.9 | - | dN+4.9 | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 |

8-18.9 | 19-37.9 | - | dN+7.3 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

19-37.9 | 38-199.9 | 8-18.9 | dN+10.7 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

38-199.9 | 200-255.9 | 19-37.9 | dN+15.1 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

200-225.9 | 256-649.9 | 38-199.9 | dN+20.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

256-649.9 | 650-999.9 | 200-255.9 | dN+24.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

650-999.9 | ≥1000.0 | 256-649.9 | dN+27.3 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 |

≥1000.0 | - | 650-999.9 | dN+38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

Application and properties

Applicable to high and low speed reciprocating motion environment, a wide range of fluids and high temperature condition. Suitable for larger gap of piston rod. Low friction, simple groove, be able to work in the medium with oil spots. Meet the standard of GB/T 15242.3.

Standard materials

Sealing ring: filled PTFE

O-ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water, gas |

Rod Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

DN h9 | D1 H9 | L1+0.2 | ||

4 | 8.9 | 2.2 | GSI4*8.9*2.2 | 5.6*1.8 |

8 | 12.9 | 2.2 | GSI8*12.9*2.2 | 9.5*1.8 |

10 | 17.3 | 3.2 | GSI10*17.3*3.2 | 12.37*2.62 |

14 | 18.9 | 2.2 | GSI14*18.9*2.2 | 15.6*1.78 |

15 | 22.3 | 3.2 | GSI15*22.3*3.2 | 17.12*2.62 |

18 | 22.9 | 2.2 | GSI18*22.9*2.2 | 20.35*1.78 |

20 | 27.3 | 3.2 | GSI20*27.3*3.2 | 21.89*2.62 |

22 | 32.7 | 4.2 | GSI22*32.7*4.2 | 26.57*3.53 |

25 | 35.7 | 4.2 | GSI25*35.7*4.2 | |

28 | 38.7 | 4.2 | GSI28*38.7*4.2 | 32.92*3.53 |

32 | 39.3 | 3.2 | GSI32*39.3*3.2 | 34.59*2.62 |

35 | 45.7 | 4.2 | GSI35*45.7*4.2 | 37.69*3.53 |

38 | 48.7 | 4.2 | GSI38*48.7*4.2 | 40.87*3.53 |

40 | 55.1 | 6.3 | GSI40*55.1*6.3 | 43.82*5.33 |

45 | 55.7 | 4.2 | GSI45*55.7*4.2 | 50.39*3.53 |

48 | 63.1 | 6.3 | GSI48*63.1*6.3 | 53.34*5.33 |

52 | 62.7 | 4.2 | GSI52*62.7*4.2 | 56.74*3.53 |

55 | 65.7 | 4.2 | GSI55*65.7*4.2 | 59.92*3.53 |

56 | 71.1 | 6.3 | GSI56*71.1*6.3 | 62.87*5.33 |

60 | 75.1 | 6.3 | GSI60*75.1*6.3 | 66.04*5.33 |

65 | 80.1 | 6.3 | GSI65*80.1*6.3 | 69.22*5.33 |

70 | 85.1 | 6.3 | GSI70*85.1*6.3 | 75.57*5.33 |

75 | 90.1 | 6.3 | GSI75*90.1*6.3 | 81.92*5.33 |

83 | 93.7 | 4.2 | GSI83*93.7*4.2 | 88.49*3.53 |

90 | 100.7 | 4.2 | GSI90*100.7*4.2 | 94.84*3.53 |

95 | 105.7 | 4.2 | GSI95*105.7*4.2 | 101.19*3.53 |

100 | 115.1 | 6.3 | GSI100*115.1*6.3 | 107.32*5.33 |

Company Features

1. Dms Seals Technology Co.,limited gathers industry elites to produce the best rod seals. - Our professional technician strictly operate machines to ensure its normal operation and produce high quality hydraulic rod seals.

2. To meet customer's requirements, DMS Seal Manufacturer always keeps the innovative technology to produce O Ring Manufacturers.

3. Dms Seals Technology Co.,limited boasts its advanced production technology. - We can customize solutions to making o-ring seal for your own hydraulic rod seals use. Inquiry!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US