DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

Wholesale oring nbrfkm piston seals DMS Seal Manufacturer Brand

-

v s

1. Fabricated using optimum quality raw materials and pioneering technology, the piston seals is used in the industry of pneumatic piston seals and hydraulic piston seals sizes.Our products mainly include rod seals, piston seals, scraper seals, rotary seals, rubber seal products and spring seals

2. hydraulic piston seals has been extensively used in hydraulic piston seals area because it possesses many merits. High-end talents and advanced technology have enabled DMS o-ring seal quality to reach the industry's leading level

3. Welcome To Browse Our Website For More Information, DMS Seals provides professional design and production of high-grade o-ring seals,In Order To Meet The Market Demand, Dms Seals Technology Co.,limited Will Continually Develop New hydraulic cylinder piston seals, If You Are Interested In Our High-Quality Products And Related Service. Pls Contact Us.

4. Dms Seals Technology Co.,limited offers lower price of o-ring seal without compromise on the product quality. DMS o-ring seal has advanced machines and equipment for its production

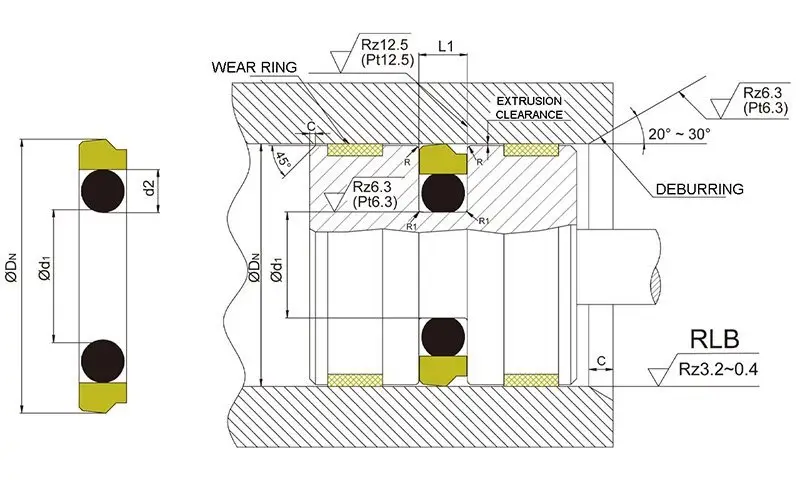

Bore Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

8-16.9 | 17-26.9 | -- | DN-4.9 | 2.2 | 0.4 | 0.30 | 0.20 | 0.15 | 1.78 |

17-26.9 | 27-59.9 | -- | DN-7.3 | 3.2 | 0.6 | 0.40 | 0.25 | 0.15 | 2.62 |

27-59.9 | 60-199.9 | 17-26.9 | DN-10.7 | 4.2 | 1.0 | 0.50 | 0.30 | 0.20 | 3.53 |

60-199.9 | 200-255.9 | 27-59.9 | DN-15.1 | 6.3 | 1.3 | 0.70 | 0.40 | 0.25 | 5.33 |

200-255.9 | 256-669.9 | 60-199.9 | DN-20.5 | 8.1 | 1.8 | 0.80 | 0.60 | 0.35 | 7.00 |

256-669.9 | 670-999.9 | 200-669.9 | DN-24.0 | 8.1 | 1.8 | 0.90 | 0.70 | 0.40 | 7.00 |

670-999.9 | -- | 256-669.9 | DN-28.0 | 9.5 | 2.5 | 1.00 | 0.80 | 0.60 | 8.40 |

-- | 1000-2000 | -- | DN-28.0 | 9.5 | 2.5 | 1.00 | 0.80 | 0.60 | 8.40 |

-- | -- | 670-999.9 | DN-38.0 | 13.8 | 3.0 | 1.20 | 0.90 | 0.60 | 12.00 |

1000-2700 | -- | -- | DN-38.0 | 13.8 | 3.0 | 1.20 | 0.90 | 0.60 | 12.00 |

Application and properties

Standard single acting sealing. Suitable for reciprocating environment, allowing larger extrusion clearances, has wide application. Dynamic and static sealing property are good, be able to work in dusty condition. Low friction, simple groove, strong adaptability to work conditions.

Standard materials

Sealing ring: filled PTFE

O-ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water and others |

Bore Dia. | Groove Dia. | Width | Order No. | O-ring Dimension |

D H9 | d1 h9 | L1+0.2 | ||

9 | 4.1 | 2.2 | GSD9*4.1*2.2 | 3.68*1.78 |

15 | 10.1 | 2.2 | GSD15*10.1*2.2 | 9.25*1.78 |

20 | 12.7 | 3.2 | GSD20*12.7*3.2 | 12.37*2.62 |

27 | 16.3 | 4.2 | GSD27*16.3*4.2 | 15.47*3.53 |

32 | 24.7 | 3.2 | GSD32*24.7*3.2 | 23.47*2.62 |

36 | 25.3 | 4.2 | GSD36*25.3*4.2 | 24*3.53 |

40 | 29.9 | 4.2 | GSD40*29.3*4.2 | 28.17*3.53 |

50 | 39.3 | 4.2 | GSD50*39.3*4.2 | 37.70*3.53 |

55 | 44.3 | 4.2 | GSD55*44.3*4.2 | 44.04*3.53 |

63 | 47.9 | 6.3 | GSD63*47.9*6.3 | 46.99*5.33 |

70 | 59.3 | 4.2 | GSD70*59.3*4.2 | 56.74*3.53 |

80 | 64.9 | 6.3 | GSD80*64.9*6.3 | 62.87*5.33 |

90 | 74.9 | 6.3 | GSD90*74.9*6.3 | 72.39*5.33 |

95 | 74.5 | 8.1 | GSD95*74.5*8.1 | 73*7.0 |

110 | 94.9 | 6.3 | GSD110*94.9*6.3 | 91.44*5.33 |

Company Features

1. The popularity of DMS Seal Manufacturer has been spreading over the world.

2. The perfected manufacturing processes and quality assurance system in DMS Seal Manufacturer's factory ensure reliable delivery of products with high quality.

3. We keeps staying at forefront of piston seals industry. Contact us!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US