DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

Top hydraulic sealer with nbr or fkm o ring for pneumatic equipment

- Dms Seals gives priority to customers and makes effort to provide them with quality services.

1. The packaging of DMS Seals hydraulic sealer will be inspected for potential quality issues. It will be checked in terms of the polybag sealing method, polybag size, appropriate labeling, barcodes, and price tags.

2. Numbers of critical tests are carried out on DMS Seals . They include structure safety testing (stability and strength) and surfaces durability testing (resistance to abrasion, impacts, scrapes, scratches, heat, and chemicals).

3. DMS Seals is carefully designed. Mechanical behavior such as statics, dynamics, the strength of materials, vibrations, reliability, and fatigue are taken into consideration.

4. The product operates nearly with no noise during the entire dehydration process. The design enables the whole body of the product to stay balanced and stable.

5. The product dehydrates the food evenly and thoroughly. During the drying process, heat conduction, and radiant heat transfer are perfectly utilized to ensure the hot air fully contacts with the food.

6. With a built-in filter system that is specially designed, this product generates very little radiation, including electromagnetic radiation and electromagnetic wave.

7. This kind of product can improve the working efficiency of work staff. The operation process is very simple and convenient.

8. The product offers wearers significant traction or friction during walking, which enables them to walk more stably and easily.

9. People will not find big shrinkage problems after frequent washing. Instead, it will become more soft to touch over time.

10. With the help of this product, people can make production at a mass level and the cost of production also is less when compared to manual works.

11. If people are wondering whether there’re some faster ways to boost their confidence, paying some attention to this product can be a good idea.

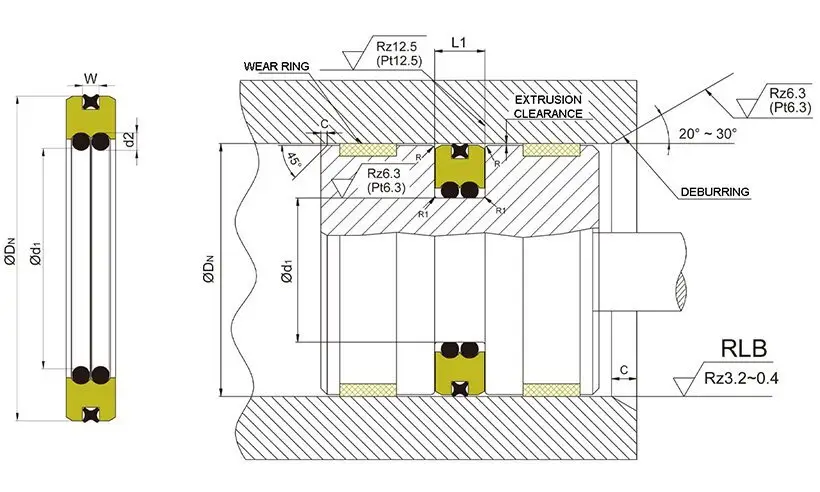

Groove Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross Section | X-Ring Seal Cross Section | |||

Standard Application | Heavy Duty Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 30MPa | d2 | W |

40 - 79.9 | 25 - 140 | DN - 10.0 | 6.3 | 0.6 | 0.3 | 0.2 | 0.15 | 2.62 | 1.78 |

80 - 132.9 | 50 - 250 | DN - 13.0 | 8.3 | 1.0 | 0.4 | 0.3 | 0.15 | 3.53 | 2.62 |

133 - 252.9 | 100 - 480 | DN - 18.0 | 12.3 | 1.3 | 0.4 | 0.3 | 0.20 | 5.33 | 3.53 |

463 - 700 | 425 - 700 | DN - 31.0 | 16.3 | 1.8 | 0.5 | 0.4 | 0.30 | 7.00 | 5.33 |

Application and properties

Apply to the working condition of fast speed, high pressure, and the necessary pressure keeping. Available for piston accumulator, clamping cylinder and positioning cylinder, especially recommended for heavy duty and large diameter applications. Double safety with low friction and high elasticity, Low gas permeability, excellent sliding performance in high pressure applications, no crawling phenomenon, simple groove structure, easy installation.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

X-Ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-60MPa | -30℃+200℃ | 3 m/s | hydraulic oil, flame retardant liquid, water and others |

Bore Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimension |

d h9 | D1 H9 | L1+0.2 | ||

40 | 30 | 6.3 | DAQ2-40*30*6.3 | 29.82*2.62 |

48 | 38 | 6.3 | DAQ2-48*38*6.3 | 37.77*2.62 |

55 | 45 | 6.3 | DAQ2-55*45*6.3 | 44.12*2.62 |

65 | 55 | 6.3 | DAQ2-65*55*6.3 | 53.64*2.62 |

80 | 67 | 8.3 | DAQ2-80*67*8.3 | 66.27*3.53 |

95 | 82 | 8.3 | DAQ2-95*82*8.3 | 78.97*3.53 |

110 | 97 | 8.3 | DAQ2-110*97*8.3 | 94.84*3.53 |

125 | 112 | 8.3 | DAQ2-125*112*8.3 | 110.72*3.53 |

140 | 122 | 12.3 | DAQ2-140*122*12.3 | 120.02*5.33 |

Company Features

1. As a well-established company, Dms Seals Technology Co.,limited mainly specializes in hydraulic sealer . Dms Seals Technology Co.,limited is a professional manufacturer of hydraulic u seal and is a leading company in the industry. DMS Seals is skilled at producing outstanding shaft wiper seal and offering the considerate service.

2. The skillful engineers of DMS Seals are very good at producing forklift hydraulic cylinder seals with exquisite performance. The advanced mechanical processing equipment and the complete modern management system are available in Dms Seals Technology Co.,limited's manufacturing plant. Advanced technology greatly improves the capacity and quality of hyd cylinder seals . Quality is the most key point for Dms Seals Technology Co.,limited during manufacturing hydraulic cylinder piston seals . The strength of Dms Seals Technology Co.,limited is almost incomparable in polyurethane piston seals field with advanced production equipment.

3. Our company has achieved sustainable growth. We've diverted our production and post-consumer waste alternatives out of waste and landfill valorization from incineration to valuable uses like recycling and upcycling. Customer-orientation is our business principle. By deepening communication, we will work hard to assist customers to design, develop, and manufacture the accurate products they need. Our goal is to provide consistent customer delight. We are putting efforts on providing innovative products at the highest level. Our company bears social responsibility. We have developed and promoted production processes that use less raw materials, which contributes to sustainability. Our company strives for excellent customer service. We will continuously seek to improve each customer's experience by listening and striving to exceed our commitments.

Top hydraulic sealer with nbr or fkm o ring for pneumatic equipment

hydraulic sealer

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US