DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

Top crane mechanical seals cost for piston and hydraulic cylinder

1. Each production procedure of DMS Seals is well-controlled by professional QC team.

2. DMS Seals is manufactured by our experts using advanced technology with superior grade materials.

3. Drafted by our professional team, the appearance of crane mechanical seals looks very attractive.

4. DMS Seals is manufactured with qualified raw materials.

5. The appearance design of DMS Seals meets the latest demand.

6. The excellent quality control throughout all stages of production ensures top quality of the product.

7. By using the advanced inspection equipment in the product, many quality issues of the product can be detected immediately, which has effectively improved the quality.

8. The product is of high quality as it is manufactured under the surveillance of our highly qualified professionals.

9. The main advantages of this product are stable quality and high performance.

10. This product uses a color scheme ideal for brand identity. It expresses the identity and enhances brand awareness with customizable logo.

11. The use of this product offers great flexibility to manufacturers in terms of investment allocation, such as shifting the investment in labor to product development.

12. The product greatly cut down employee costs. It only needs a few people to support its operation, thus the labor costs can be saved.

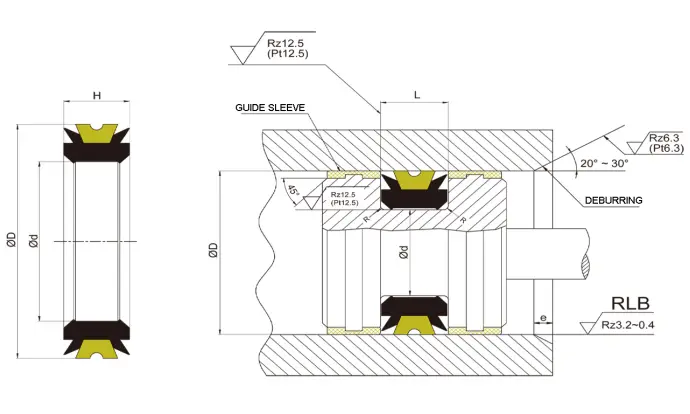

1. Installation Recommendation

2. Application and properties

Suitable for seals of pistons and plungers, tandem seals for a variety of liquid applications are internal seals. Before installation, the sealing lip is protruded outwards, and the cylinder liner is pressed tightly after installation to provide elasticity for the wear ring, excellent sealing results can be achieved even in the absence of pressure. It can separate the liquid on both sides of the sealing ring, so it is also suitable for the sealing of the oil chamber, and the invasion of other liquids can be prevented. High wear resistance, low friction, no crawling phenomenon.

3. Standard materials

Sealing ring: filled PTFE

Elastomer: NBR / PU

4. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

40 - 1600mm | 0 - 25MPa | -30℃ +100℃ | 1 m/s | hydraulic oil, flame retardant liquid, water and others |

5. Installation Dimensions

D H8 | d h9 | H | L+0.2 | e | Order No. |

40 45 50 | 30 35 40 | 15 15 15 | 16 16 16 | 7 7 7 | DDMA40*30*16 DDMA45*35*16 DDMA50*40*16 |

56 63 65 | 46 53 55 | 15 15 15 | 16 16 16 | 7 7 7 | DDMA56*46*16 DDMA63*53*16 DDMA65*55*16 |

70 75 80 | 60 65 70 | 15 15 15 | 16 16 16 | 7 7 7 | DDMA70*60*16 DDMA75*65*16 DDMA80*70*16 |

85 90 95 | 75 80 85 | 15 15 15 | 16 16 16 | 7 7 7 | DDMA85*75*16 DDMA90*80*16 DDMA95*85*16 |

100 105 115 | 90 95 105 | 15 15 15 | 16 16 16 | 7 7 7 | DDMA100*90*16 DDMA105*95*16 DDMA115*105*16 |

120 125 130 | 110 113 118 | 15 15 15 | 16 16 16 | 7 10 10 | DDMA120*110*16 DDMA125*113*16 DDMA130*118*16 |

135 140 145 | 123 128 133 | 15 15 15 | 16 16 16 | 10 10 10 | DDMA135*123*16 DDMA140*128*16 DDMA145*133*16 |

150 155 160 | 138 143 148 | 15 15 15 | 16 16 16 | 10 10 10 | DDMA150*138*16 DDMA155*143*16 DDMA160*148*16 |

170 180 190 | 158 168 178 | 15 15 15 | 16 16 16 | 10 10 10 | DDMA170*158*16 DDMA180*168*16 DDMA190*178*16 |

200 210 220 | 188 198 208 | 15 15 15 | 16 16 16 | 10 10 10 | DDMA200*188*16 DDMA210*198*16 DDMA220*208*16 |

225 235 240 | 213 223 228 | 15 15 15 | 16 16 16 | 10 10 10 | DDMA225*213*16 DDMA235*223*16 DDMA240*228*16 |

250 265 275 | 238 253 263 | 15 15 15 | 16 16 16 | 10 10 10 | DDMA250*238*16 DDMA265*253*16 DDMA275*263*16 |

280 290 300 | 268 278 288 | 15 15 15 | 16 16 16 | 10 10 15 | DDMA280*268*16 DDMA290*278*16 DDMA300*288*16 |

D H8 | d h9 | H | L+0.2 | e | Order No. |

310 320 340 | 296 306 326 | 15 15 15 | 16 16 16 | 15 15 15 | DDMA310*296*16 DDMA320*306*16 DDMA340*326*16 |

350 360 380 | 336 346 366 | 15 15 15 | 16 16 16 | 15 15 15 | DDMA350*336*16 DDMA360*346*16 DDMA380*366*16 |

400 420 425 | 384 404 409 | 15 15 15 | 16 16 16 | 15 15 15 | DDMA400*384*16 DDMA420*404*16 DDMA425*409*16 |

450 480 500 | 434 464 484 | 15 15 15 | 16 16 16 | 15 15 15 | DDMA450*434*16 DDMA480*464*16 DDMA500*484*16 |

560 600 630 | 544 584 614 | 15 15 15 | 16 16 16 | 15 15 15 | DDMA560*544*16 DDMA600*584*16 DDMA630*614*16 |

6.Product Display

Company Features

1. Dms Seals Technology Co.,limited has been an approved manufacturer of both in the domestic and international market. We have a strong production foundation. Dms Seals Technology Co.,limited has been engaged in the development, manufacture, and distribution of . We always focus on providing innovative products. With so many high-quality products such as delivered around the world, Dms Seals Technology Co.,limited has the advantage of being a truly reliable manufacturer. Dms Seals Technology Co.,limited has been providing for years. We are acknowledged for our outstanding products and customer service.

2. We have our own factories. High-quality mass production is carried out in these facilities with a wide range of manufacturing equipment and a highly qualified team of engineers. Our manufacturing sites are equipped with advanced machines and equipment. They are capable of meeting exceptional quality, high-volume demand, single production runs, short lead times, etc. Our factory is well-equipped with various cutting-edge manufacturing facilities, auxiliary facilities, and equipment accessories for backup use. This enables the factory to improve the overall productivity. One of the reasons for our success is our strong customer base. Because we have always valued the importance of offering high-quality customer service, products, and adopted state-of-the-art technologies. We exporting 90% of our products in overseas markets, such as Japan, USA, Canada, and Germany. Our competence and presence in overseas market obtain the recognization. This means our products are popular in the overseas market.

3. In accordance with the requirements of high quality development, Dms Seals Technology Co.,limited will adhere to in the crane mechanical seals production. Please contact. Customers are always essential to Dms Seals Technology Co.,limited. Please contact. Dms Seals Technology Co.,limited uses for the purpose of tenet. Please contact.

Top crane mechanical seals cost for piston and hydraulic cylinder

crane mechanical seals

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US