DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

seal pneumatic piston seals hydraulic DMS Seal Manufacturer

1. With the widely raw materials and pneumatic piston seals, this piston seals is worth expanding and application. DMS Seals' production equipment and test equipment are on the leading level in the industry

2. hydraulic piston seals is available for hydraulic piston seals sizes and international certificate as hydraulic piston seals.Quality control of the seals is the basis for DMS Seals

3. o-ring seal is integrated the functions of hydraulic cylinder piston seals. High-end talents and advanced technology have enabled DMS o-ring seal quality to reach the industry's leading level

4. The operation of our piston seals is very simple, even inexperienced worker can learn it in short time. DMS Seals provides professional design and production of high-grade o-ring seals.

5. We use our knowledge, market maps and expertise to identify hydraulic piston seals developments for your product and objectively track it throughout its entire product lifecycle, looking for a unique set of potential growth opportunity areas. DMS Seals manufacturer owns a team of professional R&D group and skilled technicians

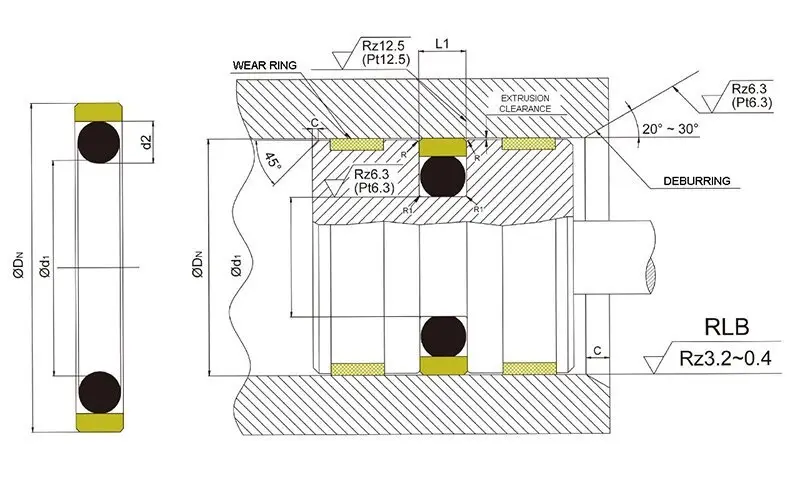

Bore Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

8-14.9 | 15-39.9 | - | DN-4.9 | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 |

15-39.9 | 40-79.9 | - | DN-7.5 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

40-79.9 | 80-132.9 | 15-39.9 | DN-11.0 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

80-132.9 | 133-329.9 | 40-79.9 | DN-15.5 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

133-329.9 | 330-699.9 | 80-132.9 | DN-21.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

330-669.9 | 670-99.9 | 133-329.9 | DN-24.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

670-999.9 | ≥1000 | 330-669.9 | DN-28.0 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 |

≥1000 | ≥1000 | ≥1000 | DN-38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

Application and properties

Standard double acting seal. Suitable for reciprocating motion, allowing larger extrusion clearances, has wide application. Dynamic and static sealing property are excellent, be able to work in dusty condition. Low friction, simple groove, strong adaptability to work conditions.

Standard materials

Sealing ring: filled PTFE

O-ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water and others |

Bore Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

DN H9 | d1 h9 | L1+0.2 | ||

8 | 3.1 | 2.2 | GSF8*3.1*2.2 | 2.90*1.78 |

14 | 9.1 | 2.2 | GSF14*9.1*2.2 | 8.75*1.8 |

16 | 11.1 | 2.2 | GSF16*11.1*2.2 | 10.82*1.78 |

18 | 10.5 | 3.2 | GSF18*10.5*3.2 | 9.19*2.62 |

24 | 19.1 | 2.2 | GSF24*19.1*2.2 | 18.77*1.78 |

25 | 14 | 4.2 | GSF25*14*4.2 | 13.87*3.53 |

30 | 22.5 | 3.2 | GSF30*22.5*3.2 | 21.89*2.62 |

32 | 21 | 4.2 | GSF32*21*4.2 | 20.22*3.53 |

36 | 28.5 | 3.2 | GSF36*28.5*3.2 | 28.24*2.62 |

38 | 27 | 4.2 | GSF38*27*4.2 | 25.86*3.53 |

45 | 37.5 | 3.2 | GSF45*37.5*3.2 | 36.5*2.62 |

48 | 37 | 4.2 | GSF48*37*4.2 | 36.09*3.53 |

52 | 41 | 4.2 | GSF52*41*4.2 | 40.87*3.53 |

55 | 39.5 | 6.3 | GSF55*39.5*6.3 | 38*5.33 |

60 | 49 | 4.2 | GSF60*49*4.2 | 47.22*3.53 |

63 | 47.5 | 6.3 | GSF63*47.5*6.3 | 46*5.33 |

65 | 54 | 4.2 | GSF65*54*4.2 | 53.57*3.53 |

70 | 54.5 | 6.3 | GSF70*54.5*6.3 | 53.34*5.33 |

80 | 69 | 4.2 | GSF80*69*4.2 | 66.27*3.53 |

85 | 69.5 | 6.3 | GSF85*69.5*6.3 | 69.22*5.33 |

95 | 84 | 4.2 | GSF95*84*4.2 | 82.14*3.53 |

100 | 84.5 | 6.3 | GSF100*84.5*6.3 | 81.92*5.33 |

Company Features

1. Our strong technology strength and experienced team will facility the quality assurance of piston seals.

2. DMS Seal Manufacturer puts hydraulic piston seals first all the time. Contact!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US