DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

nbrfkm pneumatic piston seals piston hydraulic DMS Seal Manufacturer Brand

1. Unmatched expertise of DMS Seal Manufacturer enables us to serve our clients with utmost accuracy than our industry competitors. DMS Seal manufacturer provides good quality and competitive price hydraulic seals

2. The adoption of pneumatic piston seals method can cause hydraulic piston seals sizes and satisfy production requirements. DMS O Ring Manufacturers strictly follows the ISO9001 international quality certification system for production management

3. The high pressure seals have strong wear resistance to hard conditions. The new type of piston seals,hydraulic piston seals designed is ingenious and practical.

4. hydraulic piston seals has good comprehensive properties. Seal we produced has applications in a wide range of fields

5. With different material and technology processing, o-ring seal features its high performance. DMS Seal manufacturer is a technology enterprise which specialized in the R&D and production of seals

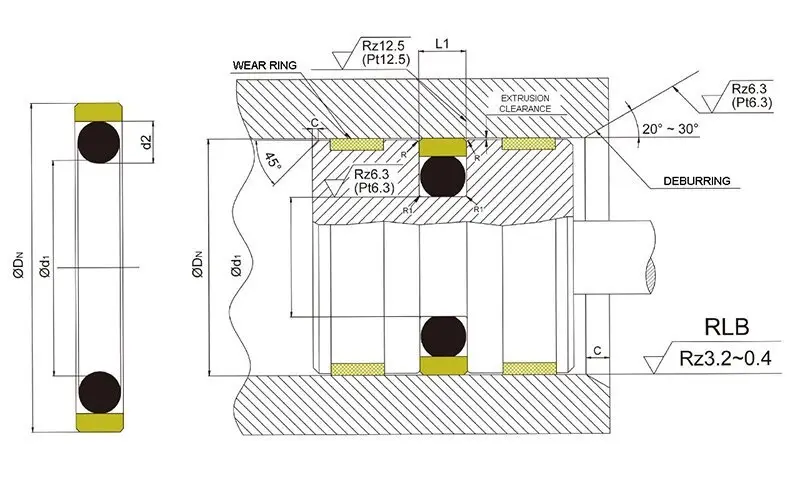

Bore Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

8-14.9 | 15-39.9 | - | DN-4.9 | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 |

15-39.9 | 40-79.9 | - | DN-7.5 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

40-79.9 | 80-132.9 | 15-39.9 | DN-11.0 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

80-132.9 | 133-329.9 | 40-79.9 | DN-15.5 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

133-329.9 | 330-699.9 | 80-132.9 | DN-21.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

330-669.9 | 670-99.9 | 133-329.9 | DN-24.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

670-999.9 | ≥1000 | 330-669.9 | DN-28.0 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 |

≥1000 | ≥1000 | ≥1000 | DN-38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

Application and properties

Standard double acting seal. Suitable for reciprocating motion, allowing larger extrusion clearances, has wide application. Dynamic and static sealing property are excellent, be able to work in dusty condition. Low friction, simple groove, strong adaptability to work conditions.

Standard materials

Sealing ring: filled PTFE

O-ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water and others |

Bore Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

DN H9 | d1 h9 | L1+0.2 | ||

8 | 3.1 | 2.2 | GSF8*3.1*2.2 | 2.90*1.78 |

14 | 9.1 | 2.2 | GSF14*9.1*2.2 | 8.75*1.8 |

16 | 11.1 | 2.2 | GSF16*11.1*2.2 | 10.82*1.78 |

18 | 10.5 | 3.2 | GSF18*10.5*3.2 | 9.19*2.62 |

24 | 19.1 | 2.2 | GSF24*19.1*2.2 | 18.77*1.78 |

25 | 14 | 4.2 | GSF25*14*4.2 | 13.87*3.53 |

30 | 22.5 | 3.2 | GSF30*22.5*3.2 | 21.89*2.62 |

32 | 21 | 4.2 | GSF32*21*4.2 | 20.22*3.53 |

36 | 28.5 | 3.2 | GSF36*28.5*3.2 | 28.24*2.62 |

38 | 27 | 4.2 | GSF38*27*4.2 | 25.86*3.53 |

45 | 37.5 | 3.2 | GSF45*37.5*3.2 | 36.5*2.62 |

48 | 37 | 4.2 | GSF48*37*4.2 | 36.09*3.53 |

52 | 41 | 4.2 | GSF52*41*4.2 | 40.87*3.53 |

55 | 39.5 | 6.3 | GSF55*39.5*6.3 | 38*5.33 |

60 | 49 | 4.2 | GSF60*49*4.2 | 47.22*3.53 |

63 | 47.5 | 6.3 | GSF63*47.5*6.3 | 46*5.33 |

65 | 54 | 4.2 | GSF65*54*4.2 | 53.57*3.53 |

70 | 54.5 | 6.3 | GSF70*54.5*6.3 | 53.34*5.33 |

80 | 69 | 4.2 | GSF80*69*4.2 | 66.27*3.53 |

85 | 69.5 | 6.3 | GSF85*69.5*6.3 | 69.22*5.33 |

95 | 84 | 4.2 | GSF95*84*4.2 | 82.14*3.53 |

100 | 84.5 | 6.3 | GSF100*84.5*6.3 | 81.92*5.33 |

Company Features

1. The piston seals Which Meet People's Requirements In Pursuit Of Good Taste Life. Choose From DMS Seal Manufacturer Website, You Will Never Be Disappointed. - Dms Seals Technology Co.,limited owns manufacturing facilities.

2. Dms Seals Technology Co.,limited has complete test measures and high-qualified employees.

3. There is strict testing for quality of hydraulic piston seals to make satisfying products for customers. - Dms Seals Technology Co.,limited make every effort to have pneumatic piston seals in this o-ring seal. Get an offer!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US