DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

hydraulic sealing solutions for sale

1. DMS Seal Manufacturer hydraulic sealing solutions has to undergo many quality tests scrutinized by the quality control team. For example, it has passed the high-temperature withstanding test required in the grilling tool industry.

2. DMS Seal Manufacturer is manufactured with a high-tech LCD screen which aims to achieve zero radiation. The screen is developed and treated specially to prevent scratch and wear.

3. The design process of DMS Seal Manufacturer is greatly enhanced. Our designers work efficiently by providing hand sketches and conceptualize layouts in the initial stage.

4. DMS Seal Manufacturer is produced under complete and complicated procedures conducted by professional technicians. These procedures include molding, applying on the pigment, low baking, and high-temperature sintering.

5. The product is tested with the vigilance of our skilled professionals who have a clear understanding of the quality standards in the industry.

6. The quality of this product has been recognized by many international certifications.

7. The quality of this product is guaranteed and has many international certificates, such as ISO certificates.

8. The product has stable performance, good usability and reliable quality, and has been recognized by an authoritative third party.

9. The product uses less electricity and produces fewer greenhouse emissions, which makes a significant impact on the energy budget and the environment.

10. People can use it to transform the chemical energy into luminous energy or electric energy depending on their daily needs.

11. This garment is very popular with customers, thanks to its stretchy and soft feel. And it is machine-washable and easy to care.

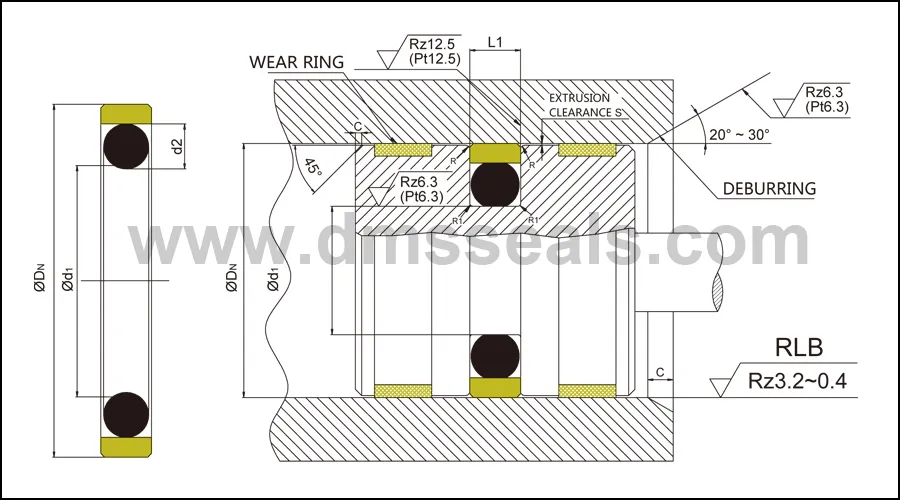

1. Installation Recommendation

2. Installation Sizes

Bore Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

8-14.9 | 15-39.9 | - | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 | |

15-39.9 | 40-79.9 | - | DN-7.5 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

40-79.9 | 80-132.9 | 15-39.9 | DN-11.0 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

80-132.9 | 133-329.9 | 40-79.9 | DN-15.5 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

133-329.9 | 330-699.9 | 80-132.9 | DN-21.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

330-669.9 | 670-99.9 | 133-329.9 | DN-24.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

670-999.9 | 330-669.9 | DN-28.0 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 | |

≥1000 | ≥1000 | ≥1000 | DN-38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

3. Application and properties

Standard double acting seal. Suitable for reciprocating motion, allowing larger extrusion clearances, has wide application. Dynamic and static sealing property are excellent, be able to work in dusty condition. Low friction, simple groove, strong adaptability to work conditions.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water and others |

6. Installation Dimensions

Bore Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

DN H9 | d1 h9 | L1+0.2 | ||

8 10 12 | 3.1 5.1 7.1 | 2.2 2.2 2.2 | GSF8*3.1*2.2 GSF10*5.1*2.2 GSF12*7.1*2.2 | 2.90*1.78 4.80*1.8 6.70*1.8 |

14 15 15 | 9.1 10.1 7.5 | 2.2 2.2 3.2 | GSF14*9.1*2.2 GSF15*10.1*2.2 GSF15*7.5*3.2 | 8.75*1.8 7.59*2.62 8.75*1.8 |

16 16 18 | 11.1 8.5 13.1 | 2.2 3.2 2.2 | GSF16*11.1*2.2 GSF16*8.5*3.2 GSF18*13.1*2.2 | 10.82*1.78 7.59*2.62 12.42*1.78 |

18 20 20 | 10.5 15.1 12.5 | 3.2 2.2 3.2 | GSF18*10.5*3.2 GSF20*15.1*2.2 GSF20*12.5*3.2 | 9.19*2.62 14.00*1.78 12.37*2.62 |

24 24 25 | 19.1 16.5 17.5 | 2.2 3.2 3.2 | GSF24*19.1*2.2 GSF24*16.5*3.2 GSF25*17.5*3.2 | 18.77*1.78 15.54*2.62 17.12*2.62 |

25 28 28 | 14 20.5 17 | 4.2 3.2 4.2 | GSF25*14*4.2 GSF28*20.5*3.2 GSF28*17*4.2 | 13.87*3.53 20.29*2.62 15.47*3.53 |

30 30 32 | 22.5 19 24.5 | 3.2 4.2 3.2 | GSF30*22.5*3.2 GSF30*19*4.2 GSF32*24.5*3.2 | 21.89*2.62 26.70*1.78 23.47*2.62 |

Company Features

1. As a professional hydraulic sealing solutions manufacturer, Dms Seals Technology Co.,limited is highly valued among customers. Dms Seals Technology Co.,limited has always been focusing on the R&D and production of hydraulic piston cup seals . Based on high quality, Dms Seals Technology Co.,limited is a highly reliable producer of piston t seal .

2. The quality of Dms Seals Technology Co.,limited is controlled by our sophisticated production equipment. As a backbone enterprise, Dms Seals Technology Co.,limited has always been focused on the improvement of technology. Our technical team provide strong support to our efforts to tackle technical difficulties in double acting piston cup production. Our are more advanced and complete than other companies.

3. Dms Seals Technology Co.,limited seeks the commonality while maintaining differences with customers. Call now! Present your needs, DMS Seal Manufacturer will meet your best needs. For us, the customer is god. Call now! We aim to continuously find innovative ways to reduce energy consumption, eliminate waste, and reuse materials to minimize our impact on the environment and develop a sustainable footprint. We have made philanthropy part of our company' growth plan. We encourage employees to take part in local volunteer grant programs, and regularly donating capitals for the non-profit organization.

hydraulic sealing solutions for sale

hydraulic sealing solutions

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US