DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

hydraulic rotary vacuum seal supplier for automotive equipment

1. The quality of DMS Seals is guaranteed by various standards that it has passed. It is manufactured in line with requirements for different aspects of GB/T and JB/T.

2. In the production process, DMS Seals is subject to strict inspection and control. It needs to pass the eco-textile test, which means azo dyes and heavy metals are excluded.

3. DMS Seals rotary vacuum seal is well designed. Its detailed design includes mechanical design, structural design, electrical control design, instrument panel design, etc.

4. The performance of the product has been greatly optimized by our dedicated technical team.

5. Our excellent R&D team has greatly improved the quality and performance of our products.

6. The product has been given a rigorous quality evaluation and inspection before shipment.

7. Product quality is fully compliant with established industry standards.

8. The product has become an essential ingredient in maintaining and improving people's quality of life and maximizing the use of food products.

9. This product is a fashion statement that can enhance people's look and personality, especially when matched with the right outfit.

10. The dangerous chemicals found in this product is generally considered too small to pose a potential risk to people health.

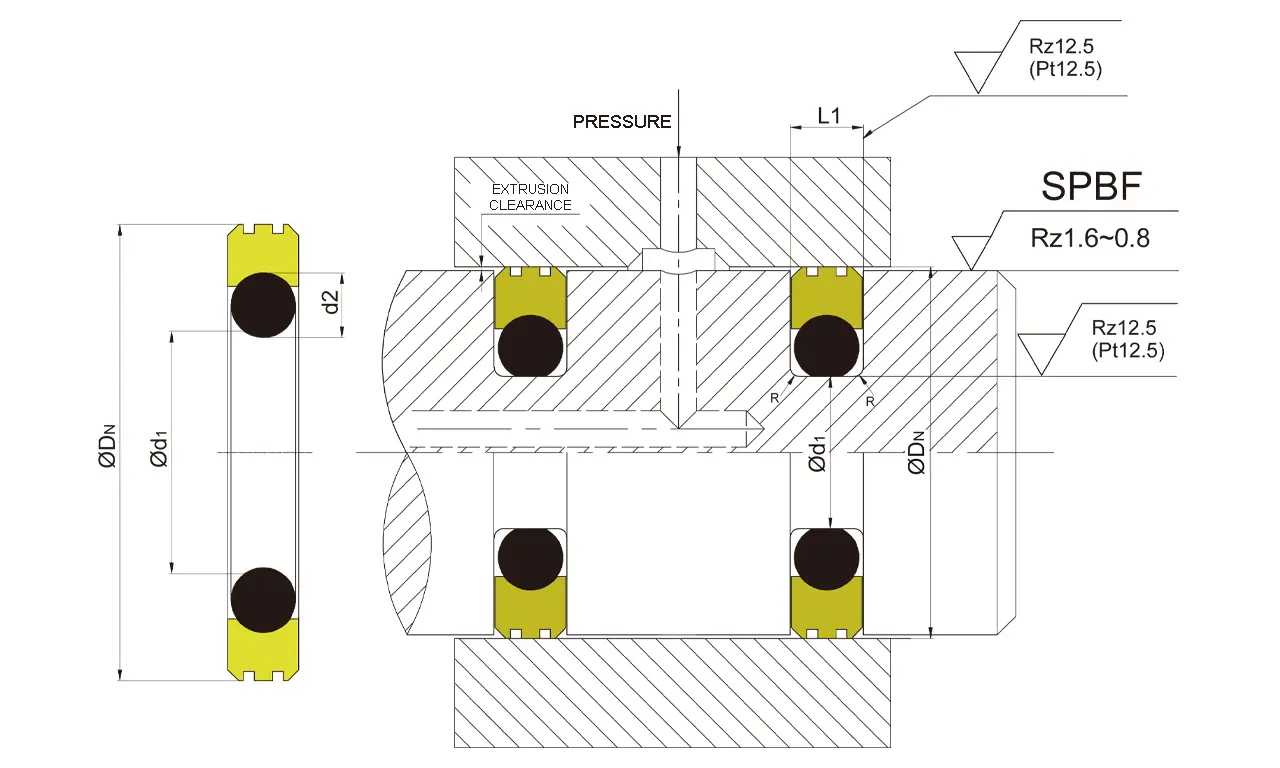

Installation Recommendation

Installation Sizes

Bore Diameter DN H9 | Groove Diameter | Groove Width | Radial Clearance S max. | Radius | Cross-Section | ||

Standard Range | Available range | d1 h9 | L1+0.2 | 32MPa | 50MPa | R1 | d2 |

| 8-39.9 | 8-135.0 | DN-4.9 | 2.2 | 0.15 | 0.10 | 0.40 | 1.78 |

| 40-79.9 | 14-250.0 | DN-7.5 | 3.2 | 0.20 | 0.15 | 0.60 | 2.62 |

| 80-132.9 | 22-460.0 | DN-11.0 | 4.2 | 0.25 | 0.20 | 1.00 | 3.53 |

| 133-329.9 | 40-675.0 | DN-15.5 | 6.3 | 0.30 | 0.25 | 1.30 | 5.33 |

| 330-669.9 | 133-690.0 | DN-21.0 | 8.1 | 0.30 | 0.25 | 1.80 | 7.00 |

| 670-999.9 | 670-999.9 | DN-28.0 | 9.5 | 0.45 | 0.30 | 2.50 | 8.40 |

Application and properties

Suitable for sealing with rotating or swinging rods, shafts, pins, rotary joints, etc. It is a rotary sealing ring that can withstand both sides pressure or alternating pressure role of the double acting effect, used in construction machinery, construction machinery and automotive equipment. It can be applied on occasions where piston rod and piston seal are required, low friction, non viscous phenomenon, simple groove, good abrasion resistance and dimensional stability.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-30MPa | -30℃+200℃ | 1 m/s | hydraulic oil, flame retardant liquid, water and others |

Bore Dia. | Groove Dia. | Groove Width | Order No. |

D H9 | d1 h9 | L+0.2 | |

8 10 12 | 3.1 5.1 7.1 | 2.2 2.2 2.2 | GNS8*3.1*2.2 GNS10*5.1*2.2 GNS12*7.1*2.2 |

14 15 16 | 9.1 10.1 11.1 | 2.2 2.2 2.2 | GNS14*9.1*2.2 GNS15*10.1*2.2 GNS16*11.1*2.2 |

17 18 20 | 12.1 13.1 15.1 | 2.2 2.2 2.2 | GNS17*12.1*2.2 GNS18*13.1*2.2 GNS20*15.1*2.2 |

80 85 90 | 69 74 79 | 4.2 4.2 4.2 | GNS80*69*4.2 GNS85*74*4.2 GNS90*79*4.2 |

95 100 102 | 84 89 91 | 4.2 4.2 4.2 | GNS95*84*4.2 GNS100*89*4.2 GNS102*91*4.2 |

105 110 115 | 94 99 104 | 4.2 4.2 4.2 | GNS105*94*4.2 GNS110*99*4.2 GNS115*104*4.2 |

120 125 130 | 109 114 119 | 4.2 4.2 4.2 | GNS120*109*4.2 GNS125*114*4.2 GNS130*119*4.2 |

210 220 230 | 194.5 204.5 214.5 | 6.3 6.3 6.3 | GNS210*194.5*6.3 GNS220*204.5*6.3 GNS230*214.5*6.3 |

240 250 280 | 224.5 234.5 264.5 | 6.3 6.3 6.3 | GNS240*224.5*6.3 GNS250*234.5*6.3 GNS280*264.5*6.3 |

350 360 400 | 329 339 379 | 8.1 8.1 8.1 | GNS350*329*8.1 GNS360*339*8.1 GNS400*379*8.1 |

Company Features

1. Since its inception, Dms Seals Technology Co.,limited has been developing rapidly. Dms Seals Technology Co.,limited is an important player in rotary vacuum seal industry. Dms Seals Technology Co.,limited is a professional production base and backbone enterprise for emerging rotary shaft seals products. Dms Seals Technology Co.,limited is a top notch oil seal finder production firm, with offices scattered around the world. DMS Seals is skillfully pursuing its path as a federal mogul oil seals manufacturer.

2. DMS Seals has been progressively improving its technology to produce ceramic shaft seal . In order to become a more capable company, DMS Seals has always introduced high-end technology. labyrinth seal pdf is produced by highly skilled technology and our experienced technical staff. Our continuous research and development work on shaft seals for pumps will ensure that we maintain technological leadership in this century. The production process of lip type oil seal adopts intelligent technology for precise control.

3. Being dedicated to providing high speed shaft seal solutions for users with our best service attitude is something DMS Seals has been always doing. Ask! Our popular piston oil seal conveys our culture and mission. Ask! Taking national oil seal cross as its mission will lead DMS Seals to its right way. Ask! To make the tenet of be an important part in the development, but also it is a source of creating value for DMS Seals. Ask!

hydraulic rotary vacuum seal supplier for automotive equipment

rotary vacuum seal

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US