DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

hydraulic rod ptfe rod seals oring DMS Seal Manufacturer

1. DMS Seals' production equipment and test equipment are on the leading level in the industry. hydraulic rod seals piston rod seal offered by DMS Seal Manufacturer are used for hydraulic rod seals online.

2. The fame of DMS Seal Manufacturer is widely increasing for its high quality rod seals. DMS Seals provides professional design and production of high-grade o-ring seals

3. Our extensive infrastructural facility that is properly equipped with all the latest amenities that help us manufacture premium quality range of products. DMS Seal manufacturer is a technology enterprise which specialized in the R&D and production of seals

4. Dms Seals Technology Co.,limited offers hydraulic rod seals buyers a rod seal catalogue-year parts warranty as well as lifetime technical support from our team of experts. As a modern sealing technology company, DMS Seal manufacturer has a wealth of experience.

5. pneumatic rod seals is easily changed via push rod seal. We can support OEM and ODM.

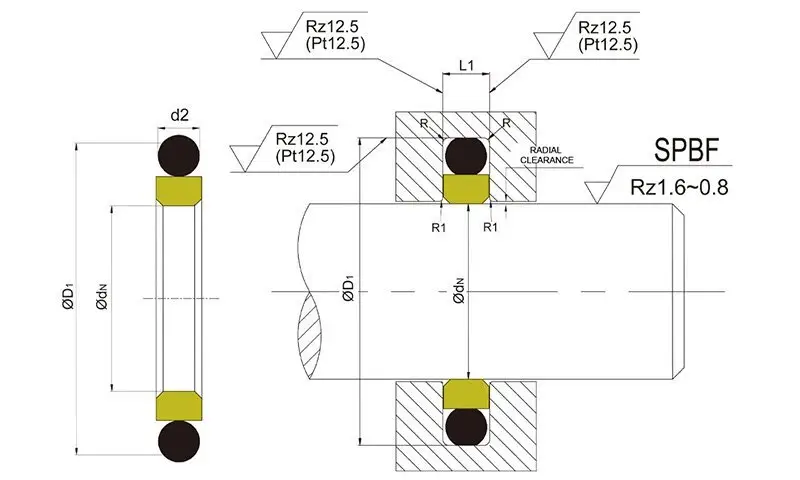

Rod Diameter dN h9 | Groove Diameter | Groove Width | Radius | colspan="3"> Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | D1 H9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

3-7.9 | 8-18.9 | - | dN+4.9 | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 |

8-18.9 | 19-37.9 | - | dN+7.3 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

19-37.9 | 38-199.9 | 8-18.9 | dN+10.7 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

38-199.9 | 200-255.9 | 19-37.9 | dN+15.1 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

200-225.9 | 256-649.9 | 38-199.9 | dN+20.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

256-649.9 | 650-999.9 | 200-255.9 | dN+24.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

650-999.9 | ≥1000.0 | 256-649.9 | dN+27.3 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 |

≥1000.0 | - | 650-999.9 | dN+38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

Application and properties

Applicable to high and low speed reciprocating motion environment, a wide range of fluids and high temperature condition. Suitable for larger gap of piston rod. Low friction, simple groove, be able to work in the medium with oil spots. Meet the standard of GB/T 15242.3.

Standard materials

Sealing ring: filled PTFE

O-ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water, gas |

Rod Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

DN h9 | D1 H9 | L1+0.2 | ||

4 | 8.9 | 2.2 | GSI4*8.9*2.2 | 5.6*1.8 |

8 | 12.9 | 2.2 | GSI8*12.9*2.2 | 9.5*1.8 |

10 | 17.3 | 3.2 | GSI10*17.3*3.2 | 12.37*2.62 |

14 | 18.9 | 2.2 | GSI14*18.9*2.2 | 15.6*1.78 |

15 | 22.3 | 3.2 | GSI15*22.3*3.2 | 17.12*2.62 |

18 | 22.9 | 2.2 | GSI18*22.9*2.2 | 20.35*1.78 |

20 | 27.3 | 3.2 | GSI20*27.3*3.2 | 21.89*2.62 |

22 | 32.7 | 4.2 | GSI22*32.7*4.2 | 26.57*3.53 |

25 | 35.7 | 4.2 | GSI25*35.7*4.2 | |

28 | 38.7 | 4.2 | GSI28*38.7*4.2 | 32.92*3.53 |

32 | 39.3 | 3.2 | GSI32*39.3*3.2 | 34.59*2.62 |

35 | 45.7 | 4.2 | GSI35*45.7*4.2 | 37.69*3.53 |

38 | 48.7 | 4.2 | GSI38*48.7*4.2 | 40.87*3.53 |

40 | 55.1 | 6.3 | GSI40*55.1*6.3 | 43.82*5.33 |

45 | 55.7 | 4.2 | GSI45*55.7*4.2 | 50.39*3.53 |

48 | 63.1 | 6.3 | GSI48*63.1*6.3 | 53.34*5.33 |

52 | 62.7 | 4.2 | GSI52*62.7*4.2 | 56.74*3.53 |

55 | 65.7 | 4.2 | GSI55*65.7*4.2 | 59.92*3.53 |

56 | 71.1 | 6.3 | GSI56*71.1*6.3 | 62.87*5.33 |

60 | 75.1 | 6.3 | GSI60*75.1*6.3 | 66.04*5.33 |

65 | 80.1 | 6.3 | GSI65*80.1*6.3 | 69.22*5.33 |

70 | 85.1 | 6.3 | GSI70*85.1*6.3 | 75.57*5.33 |

75 | 90.1 | 6.3 | GSI75*90.1*6.3 | 81.92*5.33 |

83 | 93.7 | 4.2 | GSI83*93.7*4.2 | 88.49*3.53 |

90 | 100.7 | 4.2 | GSI90*100.7*4.2 | 94.84*3.53 |

95 | 105.7 | 4.2 | GSI95*105.7*4.2 | 101.19*3.53 |

100 | 115.1 | 6.3 | GSI100*115.1*6.3 | 107.32*5.33 |

Company Features

1. Dms Seals Technology Co.,limited has evolved and expanded the business in rod seals field for many years.

2. All Work And No Play Makes Jack A Dull Boy. DMS Seal Manufacturer Is One Of The Leading hydraulic rod seals, hydraulic rod seals, piston rod seal Designers, Manufacturers And Exporter From China Get Info!

3. Dms Seals Technology Co.,limited always sticks to the core business philosophy. Ask online!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US