DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

hydraulic piston seals suppliers for light and medium hydraulic systems DMS Seal Manufacturer

1. DMS Seal Manufacturer hydraulic piston seals suppliers has passed the following physical and mechanical tests. These tests include a strength test, fatigue test, hardness test, bending test, and rigidity test. DMS Seals provides professional design and production of high-grade o-ring seals

2. The product has a wide range of applications in the industry due to its huge prospects. DMS Seals manufacturer owns a team of professional R&D group and skilled technicians

3. In addition to quality that meets industry standards, this product has a longer life than other products. The R&D teams have the ability to design and develop seals for various of complicated working condition of sealing system

4. Whether incoming detection, production process supervision or finished product inspection, the production is done with the most serious and responsible attitude. High-end talents and advanced technology have enabled DMS o-ring seal quality to reach the industry's leading level

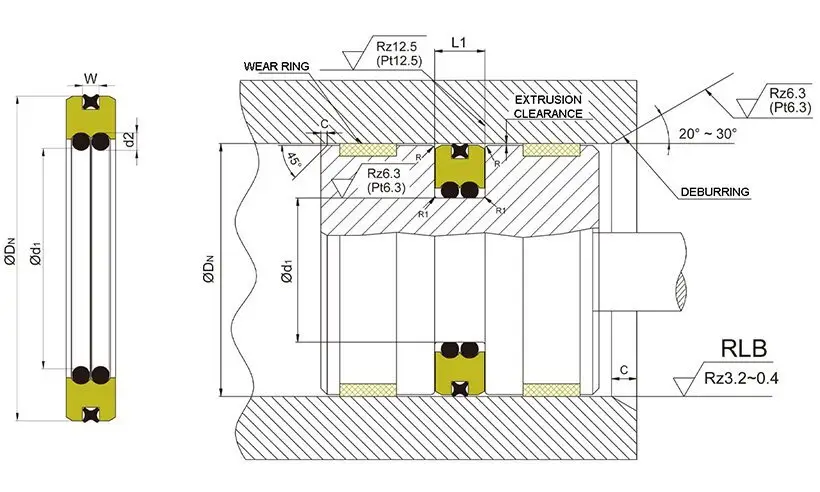

Groove Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross Section | X-Ring Seal Cross Section | |||

Standard Application | Heavy Duty Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 30MPa | d2 | W |

40 - 79.9 | 25 - 140 | DN - 10.0 | 6.3 | 0.6 | 0.3 | 0.2 | 0.15 | 2.62 | 1.78 |

80 - 132.9 | 50 - 250 | DN - 13.0 | 8.3 | 1.0 | 0.4 | 0.3 | 0.15 | 3.53 | 2.62 |

133 - 252.9 | 100 - 480 | DN - 18.0 | 12.3 | 1.3 | 0.4 | 0.3 | 0.20 | 5.33 | 3.53 |

463 - 700 | 425 - 700 | DN - 31.0 | 16.3 | 1.8 | 0.5 | 0.4 | 0.30 | 7.00 | 5.33 |

Application and properties

Apply to the working condition of fast speed, high pressure, and the necessary pressure keeping. Available for piston accumulator, clamping cylinder and positioning cylinder, especially recommended for heavy duty and large diameter applications. Double safety with low friction and high elasticity, Low gas permeability, excellent sliding performance in high pressure applications, no crawling phenomenon, simple groove structure, easy installation.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

X-Ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-60MPa | -30℃+200℃ | 3 m/s | hydraulic oil, flame retardant liquid, water and others |

Bore Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimension |

d h9 | D1 H9 | L1+0.2 | ||

40 | 30 | 6.3 | DAQ2-40*30*6.3 | 29.82*2.62 |

48 | 38 | 6.3 | DAQ2-48*38*6.3 | 37.77*2.62 |

55 | 45 | 6.3 | DAQ2-55*45*6.3 | 44.12*2.62 |

65 | 55 | 6.3 | DAQ2-65*55*6.3 | 53.64*2.62 |

80 | 67 | 8.3 | DAQ2-80*67*8.3 | 66.27*3.53 |

95 | 82 | 8.3 | DAQ2-95*82*8.3 | 78.97*3.53 |

110 | 97 | 8.3 | DAQ2-110*97*8.3 | 94.84*3.53 |

125 | 112 | 8.3 | DAQ2-125*112*8.3 | 110.72*3.53 |

140 | 122 | 12.3 | DAQ2-140*122*12.3 | 120.02*5.33 |

Company Features

1. DMS Seal Manufacturer is highly valued by more customers due to its advanced production line. We have an experienced resource purchasing team. With their many years of experience in materials purchases, they can control the purchase costs effectively while guaranteeing high-quality materials.

2. Our factory is placed in a satisfactory location. It is easily accessible to the airports and ports within an hour. This helps us minimize production and distribution costs for our company.

3. We have our own factory. Covering a large area and being equipped with advanced production lines and high-end machines, it meets needs from the rapidly developing markets. Through the accumulation of enterprise culture with years, DMS Seal Manufacturer is stronger inside to enhance the service. Get more info!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US