DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

hydraulic cylinder piston seals with ptfe nbr and pom for pneumatic equipment DMS Seal Manufacturer

- Dms Seals always adheres to the service concept of 'quality first, customer first'. We return society with high-quality products and thoughtful services.

1. The completion of DMS Seal Manufacturer hydraulic cylinder piston seals involves many technologies such as biometrics, RFID, and self-checkouts. These technologies are exclusively carried out by our professional R&D team.

2. The mold production of DMS Seal Manufacturer hydraulic cylinder piston seals is finished by CNC (computer numerically controlled) machine which ensures its highest quality to meet the challenging of customer requirements in the water park industry.

3. The production of DMS Seal Manufacturer hydraulic cylinder piston seals involves the adoption of advanced machines such as CNC cutting, milling, turning machines, CAD programming machine, and mechanical measuring and control tools.

4. The product features a clean appearance. It is coated with a special layer to effectively prevent adhesion of dust or oil smoke when being placed.

5. The product is not likely to accumulate too much heat. Its powerful cooling system is designed to maintain the proper temperature of mechanical parts, allowing it to have good heat dissipation.

6. The product features an easy operation. It has a relatively simple operating system combining a powerful processing flow and provides simple operation instruction.

7. The product can bear the most demanding industrial conditions. It is made of heavy-duty materials such as steel alloys and is not prone to rust and corrosion.

8. The product can be used in a variety of industries and will be used in a wider range of applications in the future.

9. This product is widely used in various applications.

10. This product is well received by the global market and has a broad market prospect.

11. The product is now widely available in a variety of industries and has a wide range of applications.

Application and properties

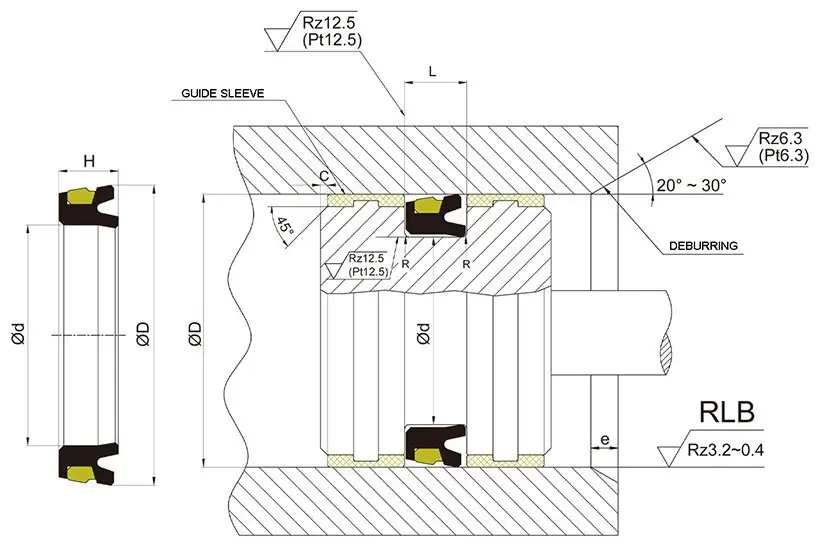

Apply to the hydraulic cylinder of piston sealing, generally used in conjunction with the guide sleeve. The seal ring and piston conforming to be a symmetric section to achieve the sealing performance. The Non-standard Y-ring has the function of sealing and provides the elastic force to the sealing ring and compensates for the abrasion. Very high pressure stability under pressure and harsh conditions, high wear resistance, low friction, no crawling phenomenon.

Standard materials

Sealing ring: filled PTFE

Y-Ring: NBR / PU

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-45MPa | -30℃+100℃ | 1m/s | hydraulic oil, flame retardant liquid, water and others |

D H8 | d h9 | H | L+0.2 | e | Order No. |

40 | 32 | 7 | 7.5 | 6 | DDA40*32*7.5 |

45 | 37 | 7 | 7.5 | 6 | DDA45*37*7.5 |

55 | 45 | 7 | 7.5 | 6 | DDA55*45*7.5 |

63 | 48 | 12 | 13 | 6 | DDA63*48*13 |

70 | 55 | 12 | 13 | 6 | DDA70*55*13 |

80 | 65 | 12 | 13 | 6 | DDA80*65*13 |

90 | 75 | 12 | 13 | 7 | DDA90*75*13 |

105 | 90 | 12 | 13 | 7 | DDA105*90*13 |

120 | 105 | 12 | 13 | 7 | DDA120*105*13 |

140 | 120 | 12 | 13 | 7 | DDA140*120*13 |

160 | 140 | 12 | 13 | 10 | DDA160*140*13 |

180 | 160 | 16 | 17 | 10 | DDA180*160*17 |

200 | 180 | 16 | 17 | 10 | DDA200*180*17 |

Company Features

1. Dms Seals Technology Co.,limited is a modern enterprise integrating science, industry and trade. DMS Seal Manufacturer has expanded and earned a solid reputation for providing high-performance piston seals . As a professional hydraulic piston seals manufacturer, Dms Seals Technology Co.,limited is highly appraised among customers. Dms Seals Technology Co.,limited is one of the world famous manufacturer for o-ring seal. Dms Seals Technology Co.,limited is a professional supplier that mainly deals in piston seals for domestic and foreign markets.

2. With advanced laboratories, DMS Seal Manufacturer can create superior piston seals with more confidence and win customers' attention. DMS Seal Manufacturer keeps introducing technologies to produce piston seals . Dms Seals Technology Co.,limited concentrates on product quality, using standard processes and rigorous quality testing. With the help of technical strength, our piston seals is of good quality. Dms Seals Technology Co.,limited has advanced production equipment and testing instruments, and its overall technical level is at the leading position in China.

3. We strive for excellence. We are not satisfied with work that is "average" or "OK." We seek innovative ways to create "better" every time. Sustainability is embedded in our operational practices. We have made great efforts in energy efficiency and pollution reduction. We also have embedded sustainability in culture. As a product manufacturer, we always look for materials that could be given a second life, continuously upgrade our packaging methods, and reducing resources wastes to improve sustainability. We are committed to respecting all laws and regulations and to ensure the health, safety, and security of our employees and subcontracted employees.

hydraulic cylinder piston seals with ptfe nbr and pom for pneumatic equipment DMS Seal Manufacturer

piston seals

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US