DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

Hydraulic cylinder phenolic resin hard guide strip wear ring

1. DMS Seal Manufacturer rubber seal ring manufacturers is elaborately manufactured using the latest advanced technology and production method.

2. DMS Seal Manufacturer bearing element is offered with the help of talented team of craftsmen.

3. The production of DMS Seal Manufacturer rubber seal ring manufacturers follows the normative conditions.

4. The raw materials of DMS Seal Manufacturer bearing element undergoes the strict selection, which is conducted by our workers.

5. Strict quality tests have been conducted to guarantee the quality of the product.

6. It is in high accordance with the quality inspection standards.

7. The product has been carefully checked by both our own QC staff and the authoritative third parties.

8. Every aspect of the product is excellent, including performance, durability, and practicality.

9. The reliability of this product guarantees a consistent performance throughout the lifetime and ultimately ensures the total cost of ownership is as low as possible.

10. DMS Seal Manufacturer is an expert in manufacturing exceptional new bearing element like our rubber seal ring manufacturers.

11. Our bearing element collection is distributed in many countries.

12. Hotel operators choose to trust and rely on Dms Seals Technology Co.,limited's unique integrated one-stop service system.

13. It is highly important for DMS Seal Manufacturer to pay attention to the quality of bearing element .

14. This product far exceeds other products in terms of performance/price ratio.

1. Installation Recommendation

2. Application and properties

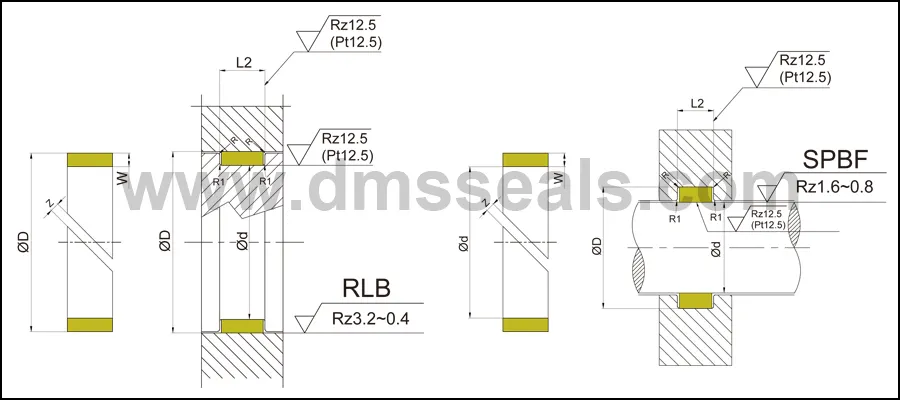

Applicable to the guiding of piston and piston rod of hydraulic cylinder and air cylinder, has the function of supporting and guiding. The guide strips with the thickness which equal to or greater than 2mm, double sided embossing could be provided, the embossing structure is conducive to the formation of lubrication micro-pit, improve micro lubrication, at the same time, it is helpful to embed tiny foreign objects and protect the sealing system.

3. Standard materials

Phenolic resin

4. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

Custom as Required | 0-100 MPa | -60℃ +120℃ | 1 m/s | hydraulic oil, emulsion, and water |

Piston: L=C × ( D - W ) - k [ mm ] D = Piston Dia. [ mm ] W = Thickness [ mm ]

Rod: L=C × ( d + W ) - k [ mm ] d = Rod Dia. [ mm ] C = 3.14 k=0.8

5. Standard groove width and standard thickness

Standard groove width

Groove width L2 | 8.1 | 10 | 15 | 20 | 5.6 | 6.3 | 9.5 | 9.7 | 12.7 | 25 | 30 | 40 | 50 | 5 | 6 | 8 | 35 | 45 |

The products of various width could be provided.

Standard thickness of product

Thickness W | 2 | 2.5 | 3 | 3.5 | 4 | 6 | 3.18 | 3.17 |

The products of various thickness could be provided.

Company Features

1. DMS Seal Manufacturer has always topped and will continue topping the bearing element market. Dms Seals Technology Co.,limited prevails over other players in the oil seal manufacturer industry by high-quality manufacture. DMS Seal Manufacturer has to date become a focus in the bearing element market. With a wealth of experience, Dms Seals Technology Co.,limited has gained a larger market share in bearing element .

2. Dms Seals Technology Co.,limited's present bearing element processing and production surpass China's overall criteria. Dms Seals Technology Co.,limited has strong product development capacities. The professional R&D strength brings great technical support to Dms Seals Technology Co.,limited. The technical level of bearing element is pretty high. Dms Seals Technology Co.,limited concentrates on technological creation and is a leader in the bearing element field.

3. The DMS Seal Manufacturer brand will further develop high-end products for customers. Call! The aim of Dms Seals Technology Co.,limited is taking the road of international brand. Call! The focus of DMS Seal Manufacturer brand is to keep optimizing its service. Call! The unforgettable development history tells DMS Seal Manufacturer people that only by continuous innovation can companies achieve significant development. Call!

Hydraulic cylinder phenolic resin hard guide strip wear ring

bearing element

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US