DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

High-quality wiper seals Suppliers for agricultural machinery

1. The production of DMS Seal Manufacturer is supported by a professional technical team. To reduce costs with high-efficiency work is the DMS's purpose

2. Dms Seals Technology Co.,limited's technical security and R&D capabilities are first class in the industry. DMS Seals manufacturer owns a team of professional R&D group and skilled technicians

3. The product can be biodegradable. It can be degraded at the high-temperature environments and hot air conditions, thus it is environmentally friendly. DMS Seals provides professional design and production of high-grade o-ring seals

4. The product has good colorfastness. Its PVC coating not only protects against the rain but also keeps it from being damaged by UV. DMS Seals' production equipment and test equipment are on the leading level in the industry

5. The product is easy to operate. Its control system adopts Siemens PLC and touch screen, which is highly automatic and convenient. High-end talents and advanced technology have enabled DMS o-ring seal quality to reach the industry's leading level

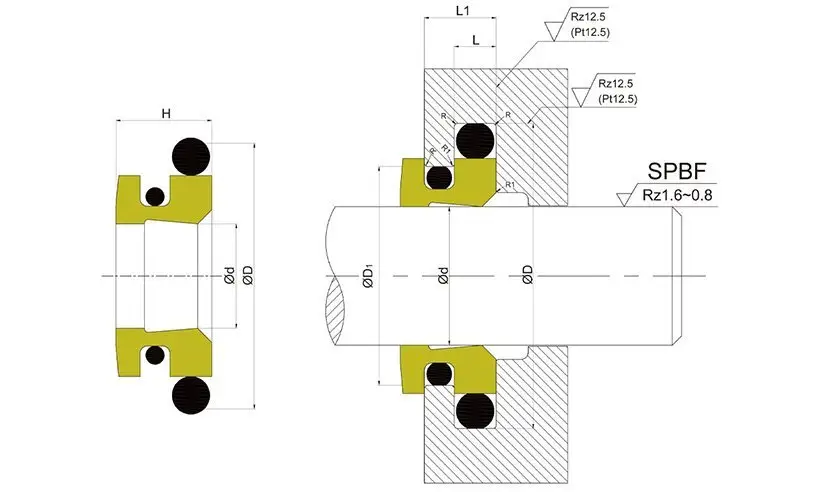

Rod Diameter d f8/h9 | Groove Diameter | Groove Width | Step Diameter | Radius | Step Width | |

Standard Application | Suitable | D H9 | L1+0.2 | D1±0.1 | R | a |

140.0-229.9 | 100.0-450.0 | d+22.2 | 6.3 | d+10.7 | 1.2 | 4.2 |

230.0-299.9 | 220.0-450.0 | d+24.2 | 6.3 | d+10.7 | 1.2 | 4.2 |

300.0-629.9 | 250.0-650.0 | d+33.0 | 8.1 | d+15.1 | 1.2 | 6.3 |

630.0-999.9 | 550.0-999.9 | d+36.5 | 9.5 | d+15.1 | 2.0 | 6.3 |

Application and properties

Applicable to agricultural hydraulic press, injection molding machine, metallurgical equipment, etc. Consisting of a sealing ring and two O-Rings as preload element, good dust scraping effect, low friction, no stick slip phenomenon, good ability of adjustment and positioning, especially for large diameter piston rods.

Standard materials

Sealing ring: filled PTFE / PU

O-Ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | -30℃+200℃ | 5 m/s | hydraulic oil, flame retardant liquid, water and others | |

d f8 | D H9 | H | L1+0.2 | L1 | Order No. |

100 | 122.2 | 13.5 | 6.3 | 4.2 | DPT2-100*122.2*6.3 |

130 | 152.2 | 13.5 | 6.3 | 4.2 | DPT2-130*152.2*6.3 |

160 | 182.2 | 13.5 | 6.3 | 4.2 | DPT2-160*182.2*6.3 |

190 | 212.2 | 13.5 | 6.3 | 4.2 | DPT2-190*212.2*6.3 |

220 | 242.2 | 13.5 | 6.3 | 4.2 | DPT2-220*242.2*6.3 |

250 | 272.2 | 13.5 | 6.3 | 4.2 | DPT2-250*272.2*6.3 |

275 | 297.2 | 13.5 | 6.3 | 4.2 | DPT2-275*297.2*6.3 |

295 | 317.2 | 13.5 | 6.3 | 4.2 | DPT2-295*317.2*6.3 |

340 | 373 | 18.4 | 8.1 | 6.3 | DPT2-340*373*8.1 |

Company Features

1. Dms Seals Technology Co.,limited adopts advanced production equipment and test equipment.

2. Dms Seals Technology Co.,limited leads the industry with the quality service. Ask!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US