DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seals Top hydraulic o rings suppliers supply for light and medium hydraulic systems

1. DMS Seals hydraulic o rings suppliers avoids being exposed to a variety of chemicals during processing. And it is processed and sanitized thoroughly for the elimination of impurities like dirt, dust, and oil.

2. DMS Seals has a very fine surface. The surface treatment is carried out in strict accordance with the highest international packaging and printing standards.

3. The manufacturing processes of DMS Seals are strictly conducted. These processes include metal materials preparation, cutting, polishing, and mechanical assembly.

4. The product is energy-friendly. Designed in a compact and energy saving electric circuit board, it consumes less power compared to other alternatives.

5. This product features eco-friendless and sustainability. Not any comburent or emission is released during its dehydrating process because it does not consume any fuel except electricity energy.

6. This product is guaranteed to be durable based on its reasonable design and fine craftsmanship which are skillfully handled by artisans.

7. The product produces little emissions and only uses less electricity. It plays a significant role in reducing carbon footprint.

8. Many producers have used this product to increase their production and income. The use of this product means saving time and labor costs.

9. The product has a usable long lifetime and needs little maintenance. Once installed, there is little part to maintain or replace or repair.

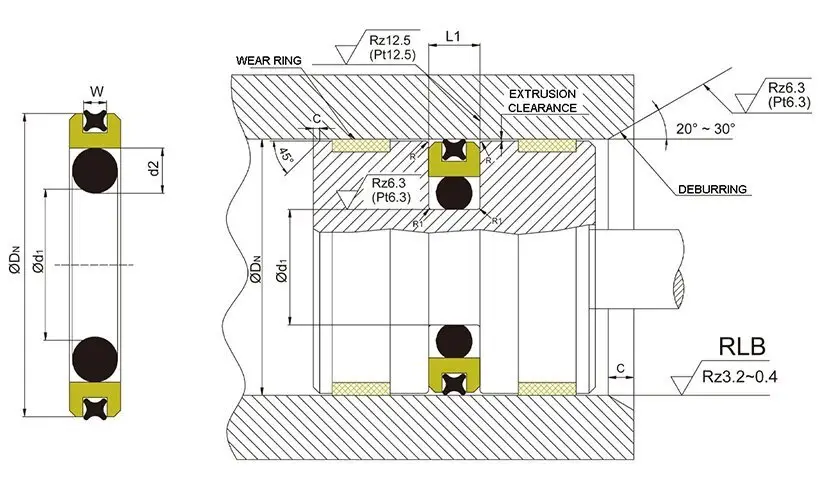

Groove Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross Section | X-Ring Seal Cross Section | |||

Standard Application | Light Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 30MPa | d2 | W |

15 - 39.9 | 40 - 79.9 | DN - 11.0 | 4.2 | 1.0 | 0.25 | 0.15 | 0.10 | 3.53 | 1.78 |

40 - 79.9 | 80 - 132.9 | DN - 15.5 | 6.3 | 1.3 | 0.3 | 020 | 0.15 | 5.33 | 1.78 |

80 - 132.9 | 133 - 252.9 | DN - 21.0 | 8.1 | 1.8 | 0.3 | 0.20 | 0.15 | 7.00 | 2.62 |

133 - 252.9 | -- | DN - 24.5 | 8.1 | 1.8 | 0.3 | 0.20 | 0.15 | 7.00 | 2.62 |

253 - 462.9 | -- | DN - 28.0 | 9.5 | 2.5 | 0.45 | 0.30 | 0.25 | 8.40 | 3.53 |

463 - 700 | -- | DN - 35.0 | 11.5 | 3.0 | 0.55 | 0.40 | 0.35 | 10.00 | 5.33 |

Application and properties

Apply to the working condition of fast speed, high pressure, and the necessary pressure keeping. Recommended for double-acting pistons as piston-type energy storage, supporting cylinder and positional cylinder. Double safety with low friction and high elasticity, good dynamic and static sealing performance, larger extrusion clearances can be allowed, at the same time with the function of holding pressure, less leakage in the hydraulic cylinder. Simple groove, small installation space, excellent sliding performance, no crawling phenomenon.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

X-Ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-40MPa | -30℃+200℃ | 2 m/s | hydraulic oil, flame retardant liquid, water and others |

Bore Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimension |

d h9 | D1 H9 | L1+0.2 | ||

70 | 59 | 4.2 | DAQ70*59*4.2 | 56.74*3.53 |

80 | 64.5 | 6.3 | DAQ80*64.5*6.3 | 62.87*5.33 |

85 | 64 | 8.1 | DAQ85*64*8.1 | 63*7.0 |

95 | 79.5 | 6.3 | DAQ95*79.5*6.3 | 78.74*5.33 |

100 | 79 | 8.1 | DAQ100*79*8.1 | 78*7.0 |

110 | 94.5 | 6.3 | DAQ110*94.5*6.3 | 91.44*5.33 |

115 | 94 | 8.1 | DAQ115*94*8.1 | 93*7.0 |

125 | 109.5 | 6.3 | DAQ125*109.5*6.3 | 107.32*5.33 |

130 | 109 | 8.1 | DAQ130*109*8.1 | 108*7.0 |

150 | 129 | 8.1 | DAQ150*129*8.1 | 126.37*7.0 |

180 | 159 | 8.1 | DAQ180*159*8.1 | 158.12*7.0 |

210 | 189 | 8.1 | DAQ210*189*8.1 | 183.52*7.0 |

240 | 219 | 8.1 | DAQ240*219*8.1 | 215.27*7.0 |

Company Features

1. Dms Seals Technology Co.,limited is identified and praised by the market in China. We are a reliable company that has an outstanding capacity in manufacturing . Dms Seals Technology Co.,limited is becoming more competitive in manufacturing and marketing in today's fierce market competition. Dms Seals Technology Co.,limited is growing steadily with increased market share after years of devotion in the hydraulic o rings suppliers manufacturing industry. Dms Seals Technology Co.,limited has long committed to the research, design, development, and production of quality since its inception.

2. With years of market exploration, we have set up our broad sales network. This helps pave the way for exporting our products to many countries and establishing a reliable partnership with many large companies around the world. We are delighted that our stunning development has won many awards. These awards are a testament to the continued care and attention we put into all of the projects. We have a highly professional QC team. By using advanced testing devices, they can ensure the highest level of product consistency and comply fully with industry guidelines. Newly introducing a set of advanced manufacturing facilities that are constructed by high-tech, the factory has counted on these facilities to achieve higher productivity and stable output. Our company has several major regional centers around the world in North and South America, India, China, Japan, Europe, and Singapore. We can bring local knowledge and local commitment wherever customers are.

3. The solid implementation of scientific principles of ensure Dms Seals Technology Co.,limited lead the world in the development trend of packing rod seals . Check now! It is a fact that DMS Seals has been keeping the idea of hydraulic seal kits suppliers first in mind since founded. Check now! has become the eternal tenet of Dms Seals Technology Co.,limited. Check now!

DMS Seals Top hydraulic o rings suppliers supply for light and medium hydraulic systems

hydraulic o rings suppliers

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US