DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seals Top carbon shaft seal company for reciprocating piston rod or piston single acting seal

- Dms Seals has been unanimously recognized by customers for high cost performance, standardized market operation and good after-sales service.

1. Through combining the advanced technology and our experienced professionals, DMS Seals carbon shaft seal is manufactured with the finest workmanship.

2. DMS Seals is manufactured using the optimum quality raw material and advanced technology.

3. During the process of production, every detail of DMS Seals is highly valued.

4. The amount of light being reflected from its surface is always sufficient. Its surface is generally coated with barium sulfate or titanium dioxide accompanied by magnesium carbonate.

5. The product is durable in use. The electrolyte used in it is made with a precise formula and features high purity, which enhances its performance.

6. This product is translucent as a whole. The woven base cloth combined with the appropriate coating allows a suitable light transmission value.

7. The product features safety in use. Controlled by an advanced and intelligent circuit, it has the overvoltage, overcurrent, and overheating protection.

8. There is strict institution in Dms Seals Technology Co.,limited for carbon shaft seal to ensure high quality.

9. Dms Seals Technology Co.,limited always adheres to the principle of 'customer first'.

10. Our carbon shaft seal will be well packed for long distance transportation.

1. Application and properties

Suitable for reciprocating piston rod or piston single acting seal, the working pressure has a wide range of adaptability, and the pressure capacity can be enhanced by increasing the tail length size or increasing the check ring.

Small friction coefficient, The contact pressure between the mating surface and the mating surface is low, and the friction between the work face and the mating surface is the smallest in all seal types. with or without lubrication can work, wear resistance, long service life.

The working medium of the sealing sleeve has wide adaptability, and the other chemicals are not reacted except soluble alkali metal, high temperature fluorine gas and three fluoride chloride.

The working temperature range is wide, and can be used for -200 ℃ to +250 ℃.

It can be used for very high speed, very low speed, micro-stroke and other special conditions.

Suitable for aviation, military and industrial sealing groove size, The standard installation groove is the same size as the standard O ring, and the size is small. It can be designed as non standard parts to meet the sealing requirements of any size groove. The groove is open or semi open.

It can be used in rotary sealing. It can adapt to large eccentricity and beating.

2. Standard materials

Sealing sleeve: PTFE

Spring: Stainless steel 304, 316

3. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range ℃ | Speed | Medium |

3 - 1600mm | 0 - 20MPa | -200 ~ +250 | 5 m/s | High and low temperature oil and water and other fluids. |

4. Installation Sizes

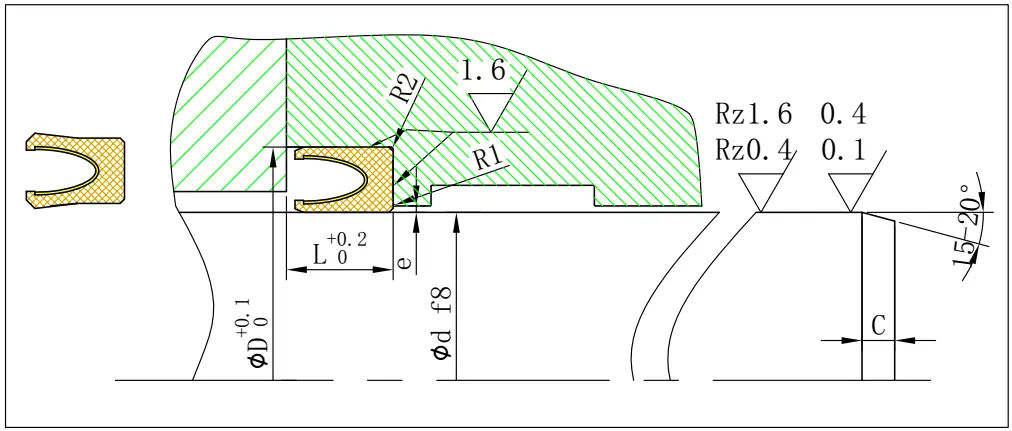

Back pressure surfaceR1=0.1 ~ 0.2, tank bottom R2=0.3 ~ 0.5, Import lengthC=(0.7 ~ 1.0)L.

Rod Diameter

| Groove Width | Groove Diameter | Radial Clearance

|

d | L | D | e |

2 ~ 10 | 2.5 | d+3.0 | 0.05 |

10 ~ 22 | 3.2 | d+4.0 | 0.065 |

22 ~ 52 | 4.7 | d+6.0 | 0.075 |

48 ~ 150 | 7.5 | d+10.0 | 0.09 |

150 ~ 400 | 11.0 | d+15.0 | 0.10 |

5. Matters needing attention

Ⅰ, The installation groove must be open or semi open, and it is recommended to be open.

Ⅱ, If the seal is for the rotating shaft, it is recommended that the surface hardness of the shaft should be no less than HRC40.

Ⅲ,Considering the adaptability of the working medium, the adaptability of the jacket and spring should be taken into account.

Ⅳ, It is better to install an anti fouling ring or a antifouling guide ring in the notch direction in front of the seal.

Company Features

1. DMS Seals covers a wide range of sales network in home and abroad market. With the development of economy, DMS Seals has gained much reputation in carbon shaft seal manufacture industry. As the economy goes, DMS Seals has been the prominent rotary seal design supplier in this industry. Equipped with complete facilities, Dms Seals Technology Co.,limited has grown to be a leading company in Dms Seals Technology Co.,limited industry. To be an enabler and promoter in stationary mechanical seal industry, DMS Seals has invested heavily in and laid out advanced technologies and professional team.

2. We have a top R&D team to keep improving quality and design for our spring energized seal design . Almost all technician talent for the industry of multi spring seal work in our Dms Seals Technology Co.,limited. With advanced technology applied in mechanical seal presentation , we take the lead in this industry.

3. Our company engages in sustainable management. We have formulated policies on the SDGs and ESG and integrated ESG elements into our budget-drafting process. We focus on social development while developing ourself. We practice social responsibility through donating money, products, or services to some underdeveloped areas. Contact us! We do business based on a customer-centric belief system. We aim to deliver a positive experience and providing unparalleled levels of attention and support for our customers. Reducing our carbon footprint is an important pillar in our sustainability commitment, and we continue to invest in energy efficiency and low-carbon technologies. Customers and others along the supply chain can see our commitment to sustainability. For example, we use reusable packaging and collapsible bulk boxes make supply chains leaner.

DMS Seals Top carbon shaft seal company for reciprocating piston rod or piston single acting seal

carbon shaft seal

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US