DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seals seal caps manufacturer wholesale for larger piston clearance

- Dms Seals has a relatively complete service management system. The professional one-stop services provided by us include product consultation, technical services, and after-sales services.

1. We adopt mature technology to produce DMS Seals . Technologies, such as mercerization, which is usually used in the high-end textile products industry has been used.

2. DMS Seals has been tested for quality. All its main components, including the engine, motor, and hydraulic components, are tested to meet our established standards.

3. Several considerations of DMS Seals seal caps manufacturer have been taken into account by our professional designers including size, color, texture, pattern, and shape.

4. By detailed discussion of , seal caps manufacturer with features like is designed.

5. It's unique help seal caps manufacturer win wider market.

6. seal caps manufacturer are recognized for their excellent properties such as .

7. People say they have no longer trouble themselves looking for fun Christmas crafts this year. For them, this product has a perfect one no matter for families or friends.

8. The product can be often applied in a variety of intense environments, ranging from the coldest climates to extreme heat.

9. Its surface is smooth and cool to touch. People say it has no coarse feeling when they touch it compared to other alternatives.

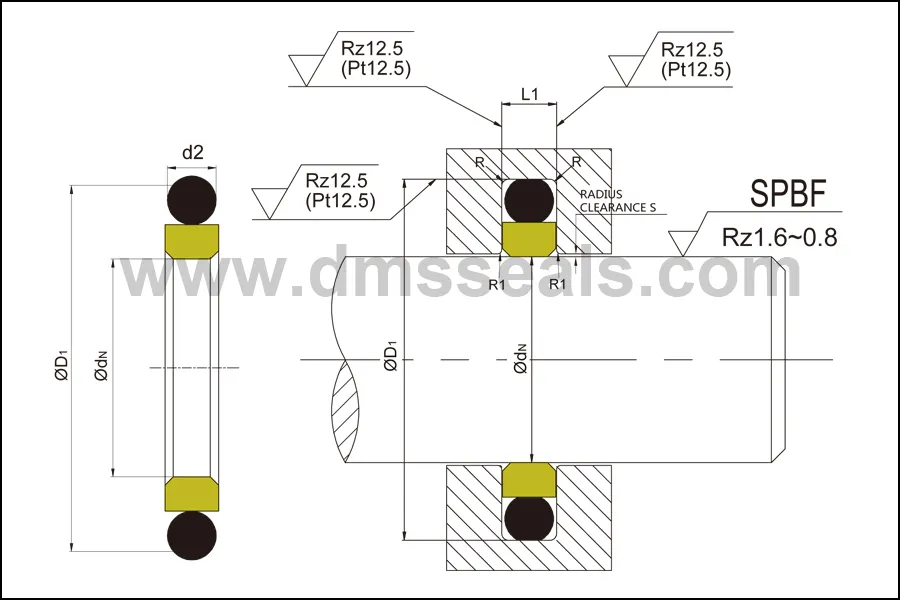

1. Installation Recommendation

2. Installation Sizes

Rod Diameter dN h9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | D1 H9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

3-7.9 | 8-18.9 | - | dN+4.9 | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 |

8-18.9 | 19-37.9 | - | dN+7.3 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

19-37.9 | 38-199.9 | 8-18.9 | dN+10.7 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

38-199.9 | 200-255.9 | 19-37.9 | dN+15.1 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

200-225.9 | 256-649.9 | 38-199.9 | dN+20.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

256-649.9 | 650-999.9 | 200-255.9 | dN+24.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

650-999.9 | ≥1000.0 | 256-649.9 | dN+27.3 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 |

≥1000.0 | - | 650-999.9 | dN+38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

3. Application and properties

Applicable to high and low speed reciprocating motion environment, a wide range of fluids and high temperature condition. Suitable for larger gap of piston rod. Low friction, simple groove, be able to work in themedium with oil spots.

Meet the standard of GB/T 15242.3.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water, gas |

6. Installation Dimensions

Rod Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

DN h9 | D1 H9 | L1+0.2 | ||

20 20 22 | 27.3 30.7 29.3 | 3.2 4.2 3.2 | GSI20*27.3*3.2 GSI20*30.7*4.2 GSI22*29.3*3.2 | 21.89*2.62 25.0*3.53 25.07*2.62 |

22 24 25 | 32.7 31.3 32.3 | 4.2 3.2 3.2 | GSI22*32.7*4.2 GSI24*31.3*3.2 GSI25*32.3*3.2 | 26.57*3.53 26.64*2.62 28.24*2.62 |

25 26 28 | 35.7 36.7 35.3 | 4.2 4.2 3.2 | GSI25*35.7*4.2 GSI26*36.7*4.2 GSI28*35.3*3.2 | 29.74*3.53 29.74*3.53 29.82*2.62 |

28 30 30 | 38.7 37.3 40.7 | 4.2 3.2 4.2 | GSI28*38.7*4.2 GSI30*37.3*3.2 GSI30*40.7*4.2 | 32.92*3.53 32.99*2.62 34.52*3.53 |

32 32 35 | 39.3 42.7 42.3 | 3.2 4.2 3.2 | GSI32*39.3*3.2 GSI32*42.7*4.2 GSI35*42.3*3.2 | 34.59*2.62 36.09*3.53 37.77*2.62 |

35 36 36 | 45.7 43.3 46.7 | 4.2 3.2 4.2 | GSI35*45.7*4.2 GSI36*43.3*3.2 GSI36*46.7*4.2 | 37.69*3.53 39.34*2.62 40.87*3.53 |

38 38 40 | 48.7 53.1 50.7 | 4.2 6.3 4.2 | GSI38*48.7*4.2 GSI38*53.1*6.3 GSI40*50.7*4.2 | 40.87*3.53 43.82*5.33 44.04*3.53 |

Company Features

1. Dms Seals Technology Co.,limited is technically advanced, which primarily manufactures seal caps manufacturer . Dms Seals Technology Co.,limited has surpassed other domestic companies in technology and capacity for manufacturing wheel seal manufacturers . As the increasing sales number shown to us, we believe DMS Seals is a promising enterprise. Over the years, Dms Seals Technology Co.,limited has experienced a rapid development for its piston rings by bore size by strong capability of . Dms Seals Technology Co.,limited is a company integrating the production and sales of rubber seal molding .

2. The premier seals manufacturing is made by technology. With a strong technical research and develop team, Dms Seals Technology Co.,limited is highly recognized by mechanical seal presentation market. The quality of crane mechanical seals has gained more and better comments from customers. Dms Seals Technology Co.,limited is capable of inventing materials for different mechanical pump seals suppliers . Every step including the product designing, material selecting, production and management are strictly controlled in Dms Seals Technology Co.,limited.

3. We aim to win the markets by quality. We will always maintain quality superiority by enhancing R&D ability and adopting international cutting-edge manufacturing technologies. We have devoted philanthropic efforts to help the environment. We initiate voluntary activities, such as clean the beach and recycle bottles and paper, aiming to reduce the negative impact on the environment. Our business goal in the coming few years is to improve customer loyalty. We will improve our customer services teams to provide a high level of customer service.

DMS Seals seal caps manufacturer wholesale for larger piston clearance

seal caps manufacturer

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US