DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seals piston seal hydraulic for business for light and medium hydraulic systems

- Dms Seals is willing to provide intimate services for consumers based on quality, flexible and adaptable service mode.

1. When manufacturing DMS Seals piston seal hydraulic , we take the quality of raw materials into consideration.

2. DMS Seals piston seal hydraulic is carefully designed as per the industry set standards.

3. DMS Seals piston seal hydraulic is designed by using the finest material and leading technology.

4. The production of DMS Seals is greatly improved and it reduces labor costs.

5. The structure of DMS Seals is more compact so as to effectively reduce labor intensity and shorten operating time.

6. The product has reliable performance. It is not likely to burn out or generate any leakage when there is a sudden blackout.

7. The product is not prone to blast. It will not have spontaneous combustion or burning even it's squeezed, dropped, and shocked.

8. It is UV resistant. Fabrics which are UV absorbing and has reflective properties are used in its manufacture to ensure protection from the sun.

9. The product emits much lower carbon emissions, which directly contributes to the reduction of greenhouse gases and reduces sea level rise possibility.

10. Most people replaced the old one with this product agreed that it does help cut down costs on electricity bills.

11. The product is able to change the layout of the room in moments and ensures floor space is used efficiently.

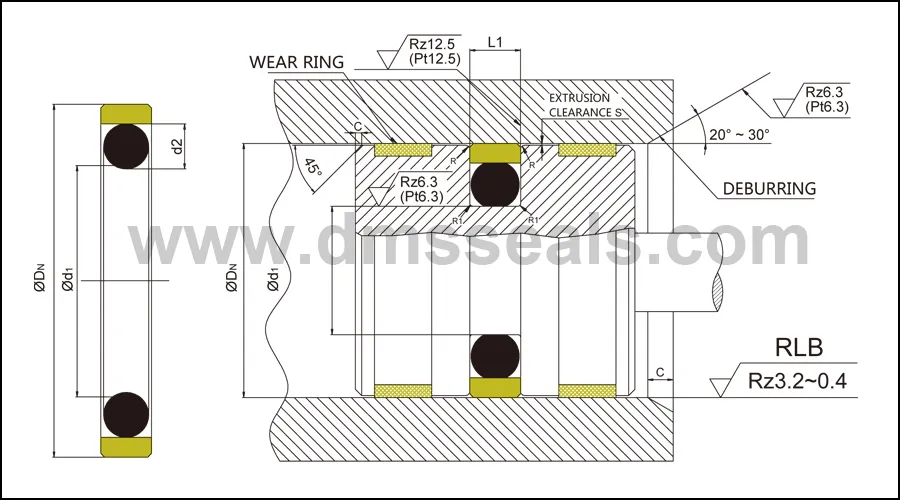

1. Installation Recommendation

2. Installation Sizes

Bore Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

8-14.9 | 15-39.9 | - | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 | |

15-39.9 | 40-79.9 | - | DN-7.5 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

40-79.9 | 80-132.9 | 15-39.9 | DN-11.0 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

80-132.9 | 133-329.9 | 40-79.9 | DN-15.5 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

133-329.9 | 330-699.9 | 80-132.9 | DN-21.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

330-669.9 | 670-99.9 | 133-329.9 | DN-24.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

670-999.9 | 330-669.9 | DN-28.0 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 | |

≥1000 | ≥1000 | ≥1000 | DN-38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

3. Application and properties

Standard double acting seal. Suitable for reciprocating motion, allowing larger extrusion clearances, has wide application. Dynamic and static sealing property are excellent, be able to work in dusty condition. Low friction, simple groove, strong adaptability to work conditions.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water and others |

6. Installation Dimensions

Bore Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

DN H9 | d1 h9 | L1+0.2 | ||

8 10 12 | 3.1 5.1 7.1 | 2.2 2.2 2.2 | GSF8*3.1*2.2 GSF10*5.1*2.2 GSF12*7.1*2.2 | 2.90*1.78 4.80*1.8 6.70*1.8 |

14 15 15 | 9.1 10.1 7.5 | 2.2 2.2 3.2 | GSF14*9.1*2.2 GSF15*10.1*2.2 GSF15*7.5*3.2 | 8.75*1.8 7.59*2.62 8.75*1.8 |

16 16 18 | 11.1 8.5 13.1 | 2.2 3.2 2.2 | GSF16*11.1*2.2 GSF16*8.5*3.2 GSF18*13.1*2.2 | 10.82*1.78 7.59*2.62 12.42*1.78 |

18 20 20 | 10.5 15.1 12.5 | 3.2 2.2 3.2 | GSF18*10.5*3.2 GSF20*15.1*2.2 GSF20*12.5*3.2 | 9.19*2.62 14.00*1.78 12.37*2.62 |

24 24 25 | 19.1 16.5 17.5 | 2.2 3.2 3.2 | GSF24*19.1*2.2 GSF24*16.5*3.2 GSF25*17.5*3.2 | 18.77*1.78 15.54*2.62 17.12*2.62 |

25 28 28 | 14 20.5 17 | 4.2 3.2 4.2 | GSF25*14*4.2 GSF28*20.5*3.2 GSF28*17*4.2 | 13.87*3.53 20.29*2.62 15.47*3.53 |

30 30 32 | 22.5 19 24.5 | 3.2 4.2 3.2 | GSF30*22.5*3.2 GSF30*19*4.2 GSF32*24.5*3.2 | 21.89*2.62 26.70*1.78 23.47*2.62 |

Company Features

1. Dms Seals Technology Co.,limited is engaged in production and sales of piston seal hydraulic and is globally well recognized. There are many positive feedback from customers for our shaft wiper seal . With the growing of economic, DMS Seals has introduced many updated technologies to meet different needs.

2. Dms Seals Technology Co.,limited has strong talents and scientific research advantages. Fully implementing the technological research will help DMS Seals to be a forward-looking hydraulic seals distributors supplier. Dms Seals Technology Co.,limited has a number of large-scale production lines. Having passed the certification of , hydraulic cylinder packing replacement are produced with high performance. The utilization of technology plays an important role in the production of cheap oil seals .

3. Customer focus is important for our company. In the future, we will always deliver customer satisfaction by listening to and exceeding customer expectations. We are committed to driving Sustainability Best Practices throughout our supply chain. We reduce CO2 emissions in the overall production value chain. Customer-oriented and value-crated is our tenet. We will work to achieve win-win cooperation and stable business friendship through honesty and trustworthiness.

DMS Seals piston seal hydraulic for business for light and medium hydraulic systems

piston seal hydraulic

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US