DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seals Latest floating seal manufacturers wholesale for piston and hydraulic cylinder

1. DMS Seals floating seal manufacturers is well designed. It is completed by using CAD design software and metal products industry-standard software to ensure the exact specifications.

2. As it is an essential part of the production process, the samples of DMS Seals are carefully handled to ensure that the feel and look are right for customers' brand.

3. DMS Seals has gone through workmanship assessment many times for optimal quality. It is checked in terms of the defects of seams and stitching, accessories safety, etc.

4. The technologies used in DMS Seals is market-based. These technologies including biometrics, RFID, and self-checkouts are evolving constantly.

5. The production process of DMS Seals is rigorously inspected. It is checked for the colorfastness of fabrics, the fastness of accessories, and the overall bag construction.

6. The product is efficient in removing dirt and contaminant. Due to its extremely small polyporous filter elements, any harmful substances, small molecule or macromolecular, will be removed effectively.

7. The product is bacteria resistant. The filter elements used in it such as membrane and pellet active carbon are highly effective in absorbing any microorganism and bacteria.

8. The product is safe enough to use. The dangers of electric leakage have been eliminated during production and all electrical components complying with relevant standards of EN or IEC.

9. This product is durable. Its stitching is secure and the inconspicuous area is free from bulk and is flat and smooth.

10. This product is hypoallergenic. The comfort layer and the support layer are sealed inside a specially-woven casing that is made to block allergens.

11. Dms Seals Technology Co.,limited has a professional after-sales service department, which is responsible for offering comprehensive after-sales service and support.

12. The quality of floating seal manufacturers is highly guaranteed by .

13. The domestic marketing network of Dms Seals Technology Co.,limited covers the whole country.

14. Dms Seals Technology Co.,limited provides marketing, sales and after-sales service support for floating seal manufacturers product.

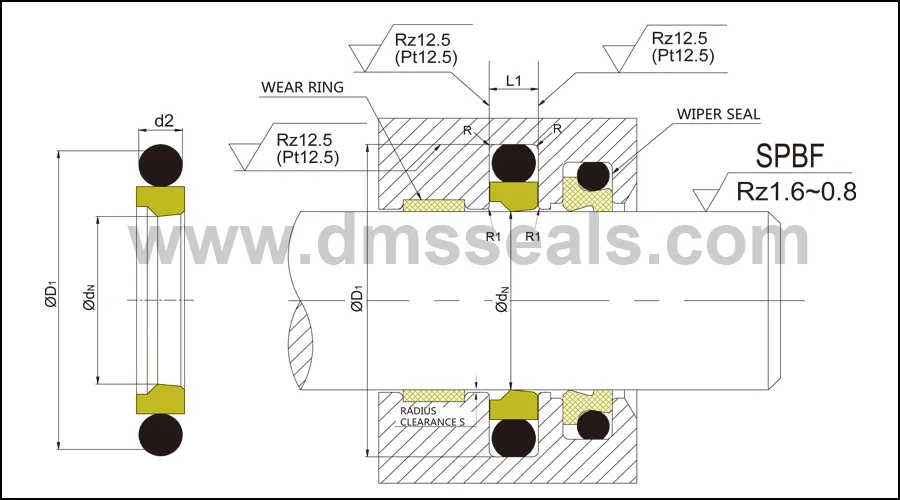

1. Installation Recommendation

2. Installation Sizes

Rod Diameter dN h9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | D1 H9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

3-7.9 | 8-18.9 | - | dN+4.9 | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 |

8-18.9 | 19-37.9 | - | dN+7.3 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

19-37.9 | 38-199.9 | 8-18.9 | dN+10.7 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

38-199.9 | 200-255.9 | 19-37.9 | dN+15.1 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

200-255.9 | 256-649.9 | 38-199.9 | dN+20.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

256-649.9 | 650-999.9 | 200-255.9 | dN+24.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

650-999.9 | ≥1000.0 | 256-649.9 | dN+27.3 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 |

≥1000.0 | - | 650-999.9 | dN+38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

3. Application and properties

Applicable to high and low speed reciprocating motion and high pressure system cylinder rod sealing. Good dimensional stability, not affected by temperature, low friction, strong corrosion resistance, could work in the situation with or without lubrication, easy installation. Meet the standards of GB/T 15242.1-94 and GB/T 15242.3-94.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water, gas |

6. Installation Dimensions

Rod Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

dN h9 | D1 H9 | L1+0.2 | ||

20 20 22 | 27.3 30.7 29.3 | 3.2 4.2 3.2 | GSJ20*27.3*3.2 GSJ20*30.7*4.2 GSJ22*29.3*3.2 | 21.89*2.62 23.39*3.53 23.47*2.62 |

22 25 25 | 32.7 32.3 35.7 | 4.2 3.2 4.2 | GSJ22*32.7*4.2 GSJ25*32.3*3.2 GSJ25*35.7*4.2 | 26.57*3.53 26.64*2.62 29.74*3.53 |

28 30 32 | 38.7 40.7 42.7 | 4.2 4.2 4.2 | GSJ28*38.7*4.2 GSJ30*40.7*4.2 GSJ32*42.7*4.2 | 31.34*3.53 34.52*3.53 36.09*3.53 |

35 36 38 | 45.7 46.7 53.1 | 4.2 4.2 6.3 | GSJ35*45.7*4.2 GSJ36*46.7*4.2 GSJ38*53.1*6.3 | 37.69*3.53 40.87*3.53 43.82*5.33 |

40 40 42 | 50.7 55.1 57.1 | 4.2 6.3 6.3 | GSJ40*50.7*4.2 GSJ40*55.1*6.3 GSJ42*57.1*6.3 | 44.04*3.53 43.82*5.33 46.99*5.33 |

45 45 50 | 55.7 60.1 60.7 | 4.2 6.3 4.2 | GSJ45*55.7*4.2 GSJ45*60.1*6.3 GSJ50*60.7*4.2 | 47.22*3.53 50.17*5.33 53.57*3.53 |

50 55 56 | 65.1 70.1 66.7 | 6.3 6.3 4.2 | GSJ50*65.1*6.3 GSJ55*70.1*6.3 GSJ56*66.7*4.2 | 56.52*5.33 59.69*5.33 59.92*3.53 |

56 56 60 | 71.1 76.5 75.1 | 6.3 8.1 6.3 | GSJ56*71.1*6.3 GSJ56*76.5*8.1 GSJ60*75.1*6.3 | 59.69*5.33 62.87*6.99 66.04*5.33 |

Company Features

1. As for the technology strength, Dms Seals Technology Co.,limited is equipped with professional and experienced engineers to produce floating seal manufacturers . DMS Seals is best known for its considerate service and finest shaft seal manufacturers . Dms Seals Technology Co.,limited grows rapidly in carbon seal manufacturer field with superior quality. Dms Seals Technology Co.,limited is an internationally competitive enterprise engaged in the field of mechanical shaft seal suppliers . Dms Seals Technology Co.,limited is a leading supplier of high-performance sog oil seal manufacturer products in China.

2. m seal manufacturer will never fall back because Dms Seals Technology Co.,limited has the most cutting edge technology. The technology capability of Dms Seals Technology Co.,limited is widely recognized by oil seal manufacturing process industry. With its finest quality, our mechanical seals houston has won more and more attention than before.

3. Dms Seals Technology Co.,limited will continue to improve the core competitiveness of our factory. Inquire! We comply with all the legal and other obligations related to the environment that we are responsible for and ensure the productive use of energy, raw material, and natural resources. We feel, act and behave as one large family – we are one – and create an engaging and inclusive workplace that favors well-being, fun, and trust to drive teamwork. Inquire! We have refined a customer-centric belief system, focusing on delivering a positive experience and providing unparalleled levels of attention and support so customers can focus on growing their business.

DMS Seals Latest floating seal manufacturers wholesale for piston and hydraulic cylinder

floating seal manufacturers

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US