DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seals Latest double lip oil seal design manufacturers for construction machinery

-

v s

1. The production of DMS Seals meets the highest standards in the rubber and plastic industry. These standards are strictly enforced and monitored by our dedicated quality team.

2. All DMS Seals are tested on installation by our professional engineers to ensure that they provide years of safe and enjoyable use.

3. The production of DMS Seals involves the adoption of advanced machines such as CNC cutting, milling, turning machines, CAD programming machine, and mechanical measuring and control tools.

4. The quality of DMS Seals is paramount. Our R&D team is always looking for new natural ingredients to guarantee the best quality product.

5. The product is 100% qualified as it meets the strict requirements for the quality inspection.

6. Under the supervision of the quality inspector, the quality of the product is checked at each different level to ensure quality.

7. Our dedicated QC team takes immediate measures to improve the quality of this product.

8. The product is utilized by a large number of people for various applications.

9. Over the years,the sales of the product has grown rapidly in the market and its market potential is viewed as vast.

10. The product is highly demanded across the globe market for its huge economic benefits.

11. The reputation and competitiveness of this range has raised apparently in recent years.

12. The product perfectly adapts to the market trend and has a great potential for wider application.

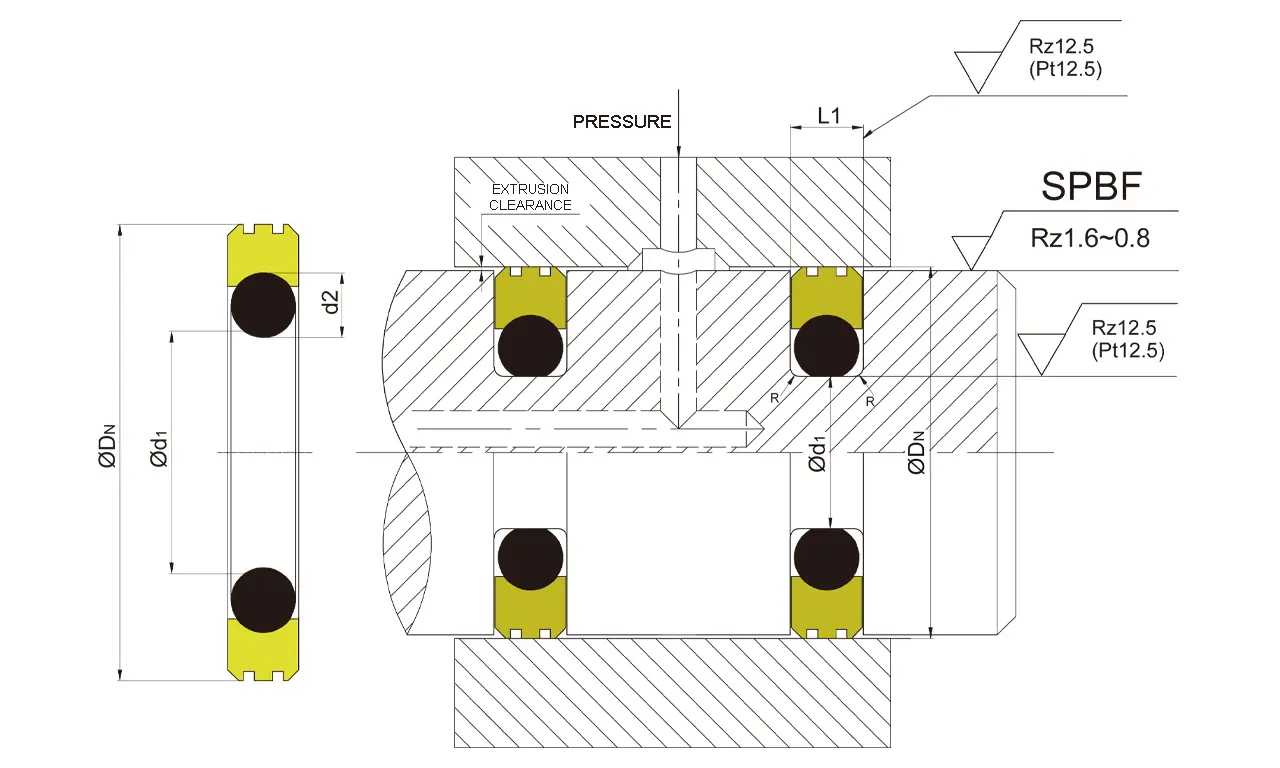

Installation Recommendation

Installation Sizes

Bore Diameter DN H9 | Groove Diameter | Groove Width | Radial Clearance S max. | Radius | Cross-Section | ||

Standard Range | Available range | d1 h9 | L1+0.2 | 32MPa | 50MPa | R1 | d2 |

| 8-39.9 | 8-135.0 | DN-4.9 | 2.2 | 0.15 | 0.10 | 0.40 | 1.78 |

| 40-79.9 | 14-250.0 | DN-7.5 | 3.2 | 0.20 | 0.15 | 0.60 | 2.62 |

| 80-132.9 | 22-460.0 | DN-11.0 | 4.2 | 0.25 | 0.20 | 1.00 | 3.53 |

| 133-329.9 | 40-675.0 | DN-15.5 | 6.3 | 0.30 | 0.25 | 1.30 | 5.33 |

| 330-669.9 | 133-690.0 | DN-21.0 | 8.1 | 0.30 | 0.25 | 1.80 | 7.00 |

| 670-999.9 | 670-999.9 | DN-28.0 | 9.5 | 0.45 | 0.30 | 2.50 | 8.40 |

Application and properties

Suitable for sealing with rotating or swinging rods, shafts, pins, rotary joints, etc. It is a rotary sealing ring that can withstand both sides pressure or alternating pressure role of the double acting effect, used in construction machinery, construction machinery and automotive equipment. It can be applied on occasions where piston rod and piston seal are required, low friction, non viscous phenomenon, simple groove, good abrasion resistance and dimensional stability.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-30MPa | -30℃+200℃ | 1 m/s | hydraulic oil, flame retardant liquid, water and others |

Bore Dia. | Groove Dia. | Groove Width | Order No. |

D H9 | d1 h9 | L+0.2 | |

8 10 12 | 3.1 5.1 7.1 | 2.2 2.2 2.2 | GNS8*3.1*2.2 GNS10*5.1*2.2 GNS12*7.1*2.2 |

14 15 16 | 9.1 10.1 11.1 | 2.2 2.2 2.2 | GNS14*9.1*2.2 GNS15*10.1*2.2 GNS16*11.1*2.2 |

17 18 20 | 12.1 13.1 15.1 | 2.2 2.2 2.2 | GNS17*12.1*2.2 GNS18*13.1*2.2 GNS20*15.1*2.2 |

80 85 90 | 69 74 79 | 4.2 4.2 4.2 | GNS80*69*4.2 GNS85*74*4.2 GNS90*79*4.2 |

95 100 102 | 84 89 91 | 4.2 4.2 4.2 | GNS95*84*4.2 GNS100*89*4.2 GNS102*91*4.2 |

105 110 115 | 94 99 104 | 4.2 4.2 4.2 | GNS105*94*4.2 GNS110*99*4.2 GNS115*104*4.2 |

120 125 130 | 109 114 119 | 4.2 4.2 4.2 | GNS120*109*4.2 GNS125*114*4.2 GNS130*119*4.2 |

210 220 230 | 194.5 204.5 214.5 | 6.3 6.3 6.3 | GNS210*194.5*6.3 GNS220*204.5*6.3 GNS230*214.5*6.3 |

240 250 280 | 224.5 234.5 264.5 | 6.3 6.3 6.3 | GNS240*224.5*6.3 GNS250*234.5*6.3 GNS280*264.5*6.3 |

350 360 400 | 329 339 379 | 8.1 8.1 8.1 | GNS350*329*8.1 GNS360*339*8.1 GNS400*379*8.1 |

Company Features

1. DMS Seals is China's most famous double lip oil seal design brand. To many consumers in many countries, DMS Seals is a number one brand of eriks oil seal catalogue . Favored by more and more customers, DMS Seals now gets more popular in the field of shaft bearing seal . As a grand exporter, Dms Seals Technology Co.,limited has been focusing on production crane mechanical seals for many years.

2. Dms Seals Technology Co.,limited emphasizes much on its innovative ability and independent R&D ability. Dms Seals Technology Co.,limited has strong technical force, advanced technology, and complete equipment. Professional technique team builds up Dms Seals Technology Co.,limited's solid technical strength and competitiveness. Processed by our experienced technicians, simmering oil seal are qualified with good stability. Dms Seals Technology Co.,limited is obviously over other companies in terms of technology foundation.

3. DMS Seals enjoys a good reputation among the piantk oil seal market. Call! Dms Seals Technology Co.,limited always hold the business concept of . Call! Dms Seals Technology Co.,limited thinks that is the best way to guarantee its development. Call! Dms Seals Technology Co.,limited always sticks to the principle of . Call!

DMS Seals Latest double lip oil seal design manufacturers for construction machinery

double lip oil seal design

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US