DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer rotary seals with nbr or fkm o ring for construction machinery

1. The design of DMS Seal Manufacturer rotary shaft seals is strictly conducted. It is carried out by our designers who think highly of parts and components safety, the whole machine safety, operation safety, and environmental safety. DMS Seals' production equipment and test equipment are on the leading level in the industry

2. Some of our customers who have used this product for several years admitted that it actually helps save a lot on their utility bills. The high pressure seals have strong wear resistance to hard conditions

3. Advanced testing equipment and perfect quality assurance system ensure the product to be of great quality. DMS o-ring seal has advanced machines and equipment for its production

4. This product is guaranteed to be stable and reliable. DMS Seals takes the lead in grasping the development trend of the industry

5. Compared with other products, this product has the advantages of long service life, stable performance and good usability. DMS Seal manufacturer is a technology enterprise which specialized in the R&D and production of seals

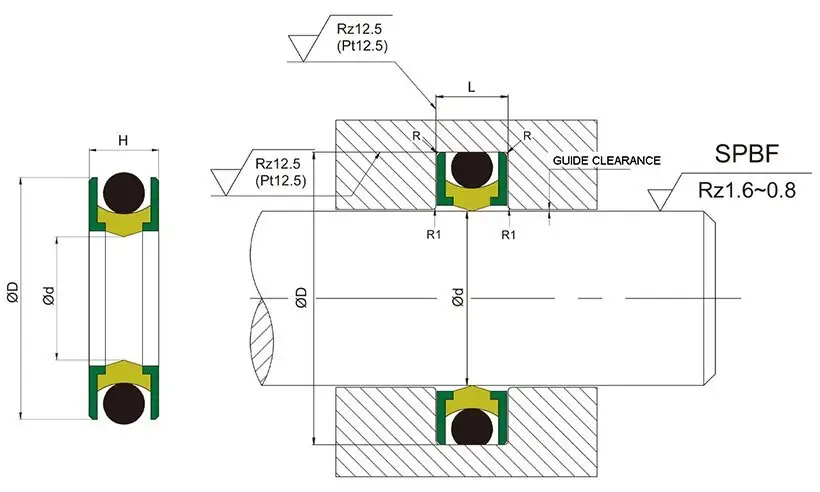

Rod Diameter | Groove Diameter | Seal Width | Groove Width | Guide Clearance S max | |

d e8 | D H9 | H | L | 0-10MPa | 15-36MPa |

50-79 | d+10.0 | 4.5 | 5.0 | 0.40-0.30 | 0.30-0.25 |

80-109 | d+13.8 | 7.0 | 7.5 | 0.45-0.35 | 0.35-0.30 |

110-299 | d+20.0 | 9.5 | 10.0 | 0.55-0.45 | 0.45-0.35 |

300-600 | d+24.0 | 12.5 | 13.0 | 0.60-0.55 | 0.55-0.45 |

Application and properties

Applicable to construction machinery, construction machinery and automotive equipment and other industrial fields. Consisting of a sealing ring, a O-Ring and two retaining rings, the sealing surface profile is specially designed to accommodate high pressure and low speed, the design of the back of the seal ring increases the contact surface and prevents rotation with the rod or shaft. Low friction, non viscous phenomenon, simple groove, good abrasion resistance and dimensional stability.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

Back-up ring: POM / PA

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-36MPa | -36℃+100℃ | 0.5 m/s | hydraulic oil, flame retardant liquid, water and others |

d e8 | D H9 | H | L | e | Order No. |

50 | 60 | 4.5 | 5 | 7 | OI50*60*4.5 |

65 | 75 | 4.5 | 5 | 7 | OI65*75*4.5 |

80 | 93.8 | 7.0 | 7.5 | 7 | OI80*93.8*7 |

95 | 108.8 | 7.0 | 7.5 | 7 | OI95*108.8*7 |

115 | 135 | 9.5 | 10 | 10 | OI115*135*9.5 |

130 | 150 | 9.5 | 10 | 10 | OI130*150*9.5 |

160 | 180 | 9.5 | 10 | 10 | OI160*180*9.5 |

190 | 210 | 9.5 | 10 | 10 | OI190*210*9.5 |

225 | 245 | 9.5 | 10 | 10 | OI225*245*9.5 |

Company Features

1. Dms Seals Technology Co.,limited has been engaged in manufacture and sales of Dms Seals Technology Co.,limited since the day of its establishment.

2. Dms Seals Technology Co.,limited has integrated advanced technology at home and abroad in the production of rotary seals .

3. Dms Seals Technology Co.,limited is committed to providing high-quality rotary shaft seals and comprehensive services. Call!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US