DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer rod seals or piston seal for business for light and medium hydraulic systems

-

v s

1. rod seals or piston seal achieves to a high level in terms of quality and safety.

2. DMS Seal Manufacturer is known for excellent quality and reliable performance.

3. DMS Seal Manufacturer rod seals or piston seal is manufactured by the sophisticated equipment and the skillful workers.

4. The production processes for DMS Seal Manufacturer rod seals or piston seal are primarily based on renewable resources.

5. DMS Seal Manufacturer is creatively designed to help customers break into the fast-growing market.

6. With the ,it's unnecessary for you to worry about quality problem.

7. rod seals or piston seal possesses such good performance as , thus has achieved good results in practical applications.

8. rod seals or piston seal is widely polulor around the world.

9. This product can help people dress in a way that makes them feel comfortable especially in day to day situations.

10. This product is soft, comfortable, and its stretchy materials also allow enough flexibility for people to move and do other things.

11. The fit of this product will mean something that people will feel more confident. It will make a big impact on the level of confidence.

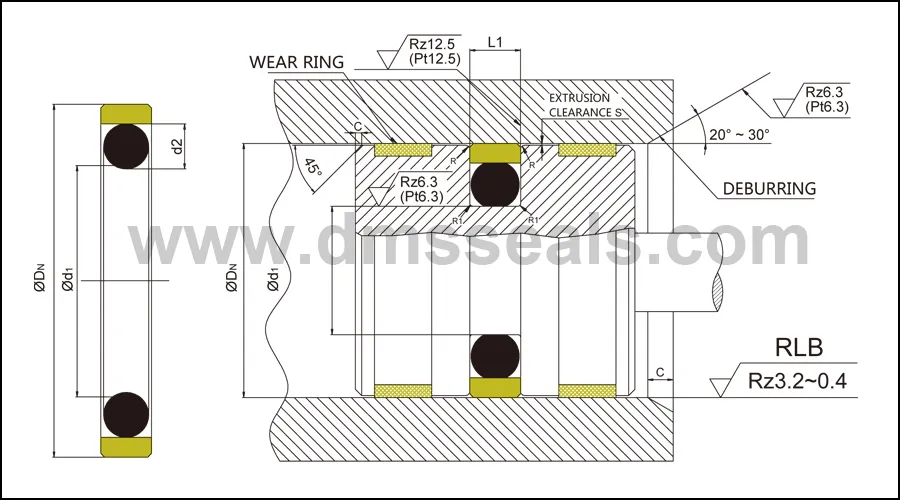

1. Installation Recommendation

2. Installation Sizes

Bore Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

8-14.9 | 15-39.9 | - | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 | |

15-39.9 | 40-79.9 | - | DN-7.5 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

40-79.9 | 80-132.9 | 15-39.9 | DN-11.0 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

80-132.9 | 133-329.9 | 40-79.9 | DN-15.5 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

133-329.9 | 330-699.9 | 80-132.9 | DN-21.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

330-669.9 | 670-99.9 | 133-329.9 | DN-24.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

670-999.9 | 330-669.9 | DN-28.0 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 | |

≥1000 | ≥1000 | ≥1000 | DN-38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

3. Application and properties

Standard double acting seal. Suitable for reciprocating motion, allowing larger extrusion clearances, has wide application. Dynamic and static sealing property are excellent, be able to work in dusty condition. Low friction, simple groove, strong adaptability to work conditions.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water and others |

6. Installation Dimensions

Bore Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

DN H9 | d1 h9 | L1+0.2 | ||

8 10 12 | 3.1 5.1 7.1 | 2.2 2.2 2.2 | GSF8*3.1*2.2 GSF10*5.1*2.2 GSF12*7.1*2.2 | 2.90*1.78 4.80*1.8 6.70*1.8 |

14 15 15 | 9.1 10.1 7.5 | 2.2 2.2 3.2 | GSF14*9.1*2.2 GSF15*10.1*2.2 GSF15*7.5*3.2 | 8.75*1.8 7.59*2.62 8.75*1.8 |

16 16 18 | 11.1 8.5 13.1 | 2.2 3.2 2.2 | GSF16*11.1*2.2 GSF16*8.5*3.2 GSF18*13.1*2.2 | 10.82*1.78 7.59*2.62 12.42*1.78 |

18 20 20 | 10.5 15.1 12.5 | 3.2 2.2 3.2 | GSF18*10.5*3.2 GSF20*15.1*2.2 GSF20*12.5*3.2 | 9.19*2.62 14.00*1.78 12.37*2.62 |

24 24 25 | 19.1 16.5 17.5 | 2.2 3.2 3.2 | GSF24*19.1*2.2 GSF24*16.5*3.2 GSF25*17.5*3.2 | 18.77*1.78 15.54*2.62 17.12*2.62 |

25 28 28 | 14 20.5 17 | 4.2 3.2 4.2 | GSF25*14*4.2 GSF28*20.5*3.2 GSF28*17*4.2 | 13.87*3.53 20.29*2.62 15.47*3.53 |

30 30 32 | 22.5 19 24.5 | 3.2 4.2 3.2 | GSF30*22.5*3.2 GSF30*19*4.2 GSF32*24.5*3.2 | 21.89*2.62 26.70*1.78 23.47*2.62 |

Company Features

1. Dms Seals Technology Co.,limited provides the integrating service of integrating design, production, sales and service of rod seals or piston seal . Dms Seals Technology Co.,limited is a leading manufacturer of piston seal manufacturers with highly advanced production machines. It is known from the comparison that Dms Seals Technology Co.,limited is advanced in hydraulic press seals industry . Dms Seals Technology Co.,limited is a large scale hi-tech company specializes in hydraulic cylinder seal compression tool .

2. Our technology takes the lead in the industry of hydraulic piston seal installation . Dms Seals Technology Co.,limited has successfully got several patents for technology. Quality is above everything in Dms Seals Technology Co.,limited. Every piece of piston seals has to go through material checking, double QC checking and etc. Our Dms Seals Technology Co.,limited has already passed relative audit.

3. We keeps staying at forefront of molded seals industry. Contact us! It is DMS Seal Manufacturer's responsibility and mission to create quality hydraulic rod seal installer . Contact us! DMS Seal Manufacturer takes the spirit of hydraulic seal design as the main line. Contact us! Dms Seals Technology Co.,limited aims to provide a bigger series of cylinder oil seal with top quality. Contact us!

DMS Seal Manufacturer rod seals or piston seal for business for light and medium hydraulic systems

rod seals or piston seal

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US