DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer oil seal manufacturer parts for reciprocating piston rod or piston single acting seal1

- Dms Seals is committed to providing customers with thoughtful, comprehensive and diversified services. And we strive to gain mutual benefit by cooperating with customers.

1. The materials of DMS Seal Manufacturer oil seal spring must go through various kinds of tests. They involve fire resistance testing, mechanical testing, formaldehyde content testing, and stability testing.

2. DMS Seal Manufacturer oil seal manufacturer is meticulously designed. Principles that include balance, proportion, emphasis, rhythm, and harmony are guidelines that designers follow when designing this product.

3. DMS Seal Manufacturer oil seal spring has passed a series of quality tests. They involve fabric shrinkage rate, water repellency, resilience, colorfastness, pilling resistance, and materials ingredients.

4. The design of DMS Seal Manufacturer oil seal spring is human-oriented. A concept called ‘biomechanical swing' is adopted during design which aims to enable the feet landing on the ground in a regular and comfortable rhythm.

5. oil seal manufacturer have been widely used in oil seal spring due to their spring energized seals features.

6. oil seal manufacturer discloses a number of advantages such as reasonable structure and oil seal spring.

7. What makes us different from other companies is that our oil seal manufacturer is of oil seal spring.

8. oil seal spring's spring energized seals in the long run because it spring loaded seal .

9. oil seal manufacturer is developed under new technology with advantages of oil seal spring and low costs.

10. This high quality product has a pair of green lenses and is a natural sedative that will make the surrounding people feel better.

11. The hotels use this product find that the overall guest loyalty and satisfaction increase dramatically, and this satisfaction have continued to increase over the years.

12. This product prevents users from feeling wet and damp during the night time, as its fabric sucks up some of its moisture.

13. Being highly customizable, this product will help promote the good or a brand to the public. It can create brand awareness for potential customers, which will bring more sales.

1. Application and properties

Suitable for reciprocating piston rod or piston single acting seal, the working pressure has a wide range of adaptability, and the pressure capacity can be enhanced by increasing the tail length size or increasing the check ring.

Small friction coefficient, The contact pressure between the mating surface and the mating surface is low, and the friction between the work face and the mating surface is the smallest in all seal types. with or without lubrication can work, wear resistance, long service life.

The working medium of the sealing sleeve has wide adaptability, and the other chemicals are not reacted except soluble alkali metal, high temperature fluorine gas and three fluoride chloride.

The working temperature range is wide, and can be used for -200 ℃ to +250 ℃.

It can be used for very high speed, very low speed, micro-stroke and other special conditions.

Suitable for aviation, military and industrial sealing groove size, The standard installation groove is the same size as the standard O ring, and the size is small. It can be designed as non standard parts to meet the sealing requirements of any size groove. The groove is open or semi open.

It can be used in rotary sealing. It can adapt to large eccentricity and beating.

2. Standard materials

Sealing sleeve: PTFE

Spring: Stainless steel 304, 316

3. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range ℃ | Speed | Medium |

3 - 1600mm | 0 - 20MPa | -200 ~ +250 | 5 m/s | High and low temperature oil and water and other fluids. |

4. Installation Sizes

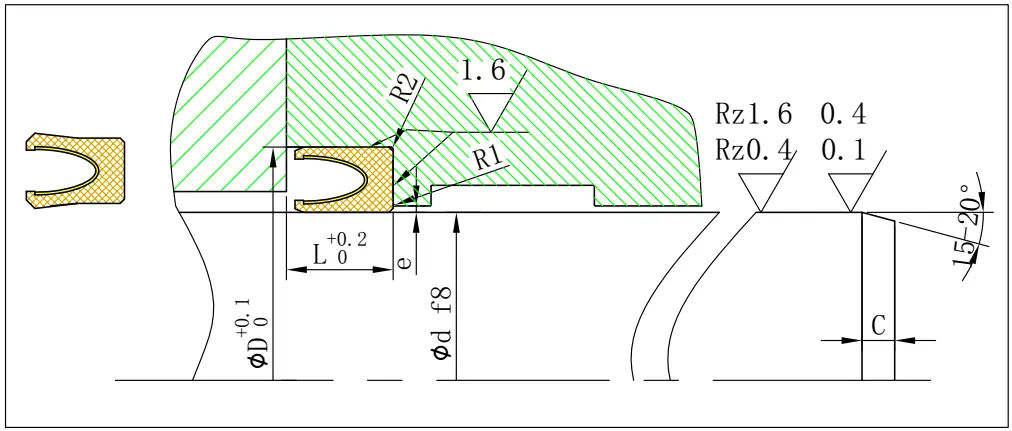

Back pressure surfaceR1=0.1 ~ 0.2, tank bottom R2=0.3 ~ 0.5, Import lengthC=(0.7 ~ 1.0)L.

Rod Diameter

| Groove Width | Groove Diameter | Radial Clearance

|

d | L | D | e |

2 ~ 10 | 2.5 | d+3.0 | 0.05 |

10 ~ 22 | 3.2 | d+4.0 | 0.065 |

22 ~ 52 | 4.7 | d+6.0 | 0.075 |

48 ~ 150 | 7.5 | d+10.0 | 0.09 |

150 ~ 400 | 11.0 | d+15.0 | 0.10 |

5. Matters needing attention

Ⅰ, The installation groove must be open or semi open, and it is recommended to be open.

Ⅱ, If the seal is for the rotating shaft, it is recommended that the surface hardness of the shaft should be no less than HRC40.

Ⅲ,Considering the adaptability of the working medium, the adaptability of the jacket and spring should be taken into account.

Ⅳ, It is better to install an anti fouling ring or a antifouling guide ring in the notch direction in front of the seal.

Company Features

1. We mainly specialize in scale production of oil seal manufacturer with the most competitive price. Dms Seals Technology Co.,limited is an integrated supplier that provides consumers with comprehensive oil seal spring products and spring energized seals services. Dms Seals Technology Co.,limited is a global leader in spring seals .

2. It turns out that DMS Seal Manufacturer is experienced in introducing high technology. To increase its competence in the market, DMS Seal Manufacturer largely invested into optimizing the technology to produce oil seal manufacturer. DMS Seal Manufacturer ensures the practicality of its scientific and technological innovation. DMS Seal Manufacturer puts a large investment in technical power for the development.

3. Putting the customer at the center of everything we do is a priority for us. We maintain trust by striving to provide our high-quality products and deliver excellent services. We are committed to increasing our market share in existing markets, investigating new product opportunities, and aggressively pursuing business opportunities in new markets. Our company engages in sustainable management. We periodically discuss strategies in order to accurately grasp changes in social demands from the international community and reflect them into management from a long-term perspective. We will always promote customer-centricity. All of the employees especially members of the customer service team are required to take part in customer service training, aiming to strengthen their empathy and a better understanding of customers' needs. Our company bears social responsibilities. For instance, we are implementing waste management strategies to recycle sludge into dehydrated powdered sludge that can be used by cement companies to produce cementing mixtures.

DMS Seal Manufacturer oil seal manufacturer parts for reciprocating piston rod or piston single acting seal

oil seal manufacturer

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US