DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer New molded seals Supply for pneumatic equipment

1. The manufacturing process of DMS Seal Manufacturer molded seals covers several few stages. They are mainly production pattern making, pattern design, fabric sourcing, fabric pre-drinking, shrinkage, grading, layout, cutting, sewing, and ironing.

2. The quality of DMS Seal Manufacturer is guaranteed by a number of factors. The performance, reliability, durability, visual and perceived quality of the garment can be counted on the excellent workmanship.

3. Seven fundamentals of good furniture design are applied on DMS Seal Manufacturer . They are Contrast, Proportion, Shape or Form, Line, Texture, Pattern, and Colour.

4. The quality inspections of DMS Seal Manufacturer will be routinely carried out. It will be inspected with regard to stitching defects, seam defects, color shading, fabric construction, and colorfastness.

5. The product has a good energy absorption capacity. The finish materials on the surface of its absorber are useful for enhancing the efficiency of energy storage.

6. The product is corrosion resistance. It has been processed with powder coating which forms a protective layer on its surface.

7. The product is free of electric leakage problems. Its circuit design has been optimized with an insulation protection system that would prevent any electrical risk.

8. Due to its unparalleled advantages, the product has been widely demanded in the market.

9. This product is widely used in the market due to its huge economic potential.

10. This product is perfectly suited to the most practical part of our lives.

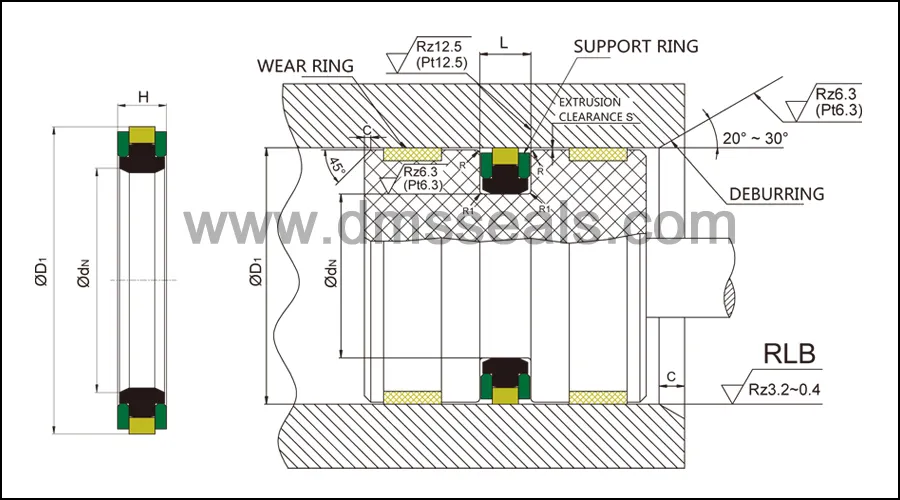

1. Installation Recommendation

2. Application and properties

Suitable for long stroke, a wide range of fluids and high temperature occasions. The application of heavy duty double acting piston sealing under high pressure conditions is excellent. Applicable to larger piston clearance , it has good leakage control, extrusion resistance and wear resistance in heavy duty and construction machinery cylinder piston sealing system. Good static sealing property, simple groove structure, larger extrusion clearances can be allowed, be able to work in dusty condition.

3. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

Back-up ring: POM / PA

4. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

50 - 350mm | 0 - 50MPa | -30℃ +100℃ | 1.5 m/s | hydraulic oil, flame retardant liquid, water and others |

5. Installation Dimensions

Nominal Size of Packing, and Housing dimensions | L+0.2 | Order No. | ||

D1 | dN | H | ||

50 55 60 | 36 41 46 | 8.5 8.5 8.5 | 9 9 9 | SPGW50*36*8.5 SPGW55*41*8.5 SPGW60*46*8.5 |

63 65 70 | 48 50 55 | 10.5 10.5 10.5 | 11 11 11 | SPGW63*48*10.5 SPGW65*50*10.5 SPGW70*55*10.5 |

75 80 85 | 60 65 70 | 10.5 10.5 10.5 | 11 11 11 | SPGW75*60*10.5 SPGW80*65*10.5 SPGW85*70*10.5 |

90 95 100 | 75 80 85 | 10.5 10.5 12 | 11 11 12.5 | SPGW90*75*10.5 SPGW95*80*10.5 SPGW100*85*12 |

105 110 115 | 90 95 100 | 12 12 12 | 12.5 12.5 12.5 | SPGW105*90*12 SPGW110*95*12 SPGW115*100*12 |

120 125 130 | 105 102 107 | 12 15.5 15.5 | 12.5 16 16 | SPGW120*105*12 SPGW125*102*15.5 SPGW130*107*15.5 |

135 140 145 | 112 117 122 | 15.5 15.5 15.5 | 16 16 16 | SPGW135*112*15.5 SPGW140*117*15.5 SPGW145*122*15.5 |

150 155 160 | 127 132 137 | 15.5 15.5 15.5 | 16 16 16 | SPGW150*127*15.5 SPGW155*132*15.5 SPGW160*137*15.5 |

165 170 180 | 142 147 157 | 15.5 15.5 15.5 | 16 16 16 | SPGW165*142*15.5 SPGW170*147*15.5 SPGW180*157*15.5 |

185 190 200 | 162 167 177 | 15.5 15.5 15.5 | 16 16 16 | SPGW185*162*15.5 SPGW190*167*15.5 SPGW200*177*15.5 |

210 220 225 | 187 197 202 | 15.5 15.5 17 | 16 16 17.5 | SPGW210*187*15.5 SPGW220*197*15.5 SPGW225*202*15.5 |

230 240 250 | 207 217 222 | 17 17 17 | 17.5 17.5 17.5 | SPGW230*207*15.5 SPGW240*217*15.5 SPGW250*222*17 |

260 270 280 | 232 242 252 | 17 17 17 | 17.5 17.5 17.5 | SPGW260*232*17 SPGW270*242*17 SPGW280*252*17 |

300 320 350 | 272 292 322 | 17 17 17 | 17.5 17.5 17.5 | SPGW300*272*17 SPGW320*292*17 SPGW350*322*17 |

Company Features

1. Dms Seals Technology Co.,limited has been known as a reputable manufacturer who pays high attention to the quality of . Since starting business many years ago, Dms Seals Technology Co.,limited has always manufactured and supplied quality in the market. As a dedicated manufacturer based in China, Dms Seals Technology Co.,limited has strong competence in developing and manufacturing. As a rapidly growing manufacturer specializing in , Dms Seals Technology Co.,limited is now serving many countries and region worldwide with increasing market share.

2. It is important for DMS Seal Manufacturer to keep innovative especially in the technology in this changing society. By performing the technology, DMS Seal Manufacturer has stronger technical force to manufacture molded seals . In the meantime training its own developing power, Dms Seals Technology Co.,limited also researches and develops high quality hydraulic sealer together with many of scientific research institutions.

3. DMS Seal Manufacturer will continue to improve productivity and production quality and provide innovative products. Call now! DMS Seal Manufacturer adheres to the tenet of cultivating corporate culture always. Call now! Dms Seals Technology Co.,limited will promote its service quality to serve customers. Call now!

DMS Seal Manufacturer New molded seals Supply for pneumatic equipment

molded seals

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US