DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer mechanical seal pot manufacturers for aviation

-

v s

1. A variety of processing methods are used in DMS Seal Manufacturer production. There are mainly turning, drilling, cutting, grinding, CNC machining and honing.

2. DMS Seal Manufacturer is fully tested by our quality control professionals, who test the tension and fatigue of each style of bedding.

3. Different high technologies are applied in the development of DMS Seal Manufacturer . It is developed and upgraded under technologies such as mechanical systems technology, automatic control technology, sensing technology, and servo-drive technology.

4. Manufacturing DMS Seal Manufacturer involves a wide range of stages. They include metal materials purchasing, parts processing, welding, assembly, and testing.

5. The manufacture of DMS Seal Manufacturer mechanical seal pot requires the use of different facilities. It is processed under stamping, coating, painting, and drying equipment that features high performance and efficiency.

6. Thanks to its special and its high-tech , mechanical seal pot adds high-end experience to any user.

7. Features of has brought brand favorability to DMS Seal Manufacturer and its business.

8. mechanical seal pot functions in the performance of and .

9. 's high performance can meet the requirements of many special industries for mechanical seal pot .

10. Its performance is guaranteed by well-selected materials.

11. Except for its good quality, our mechanical seal pot is also famous among customers for its service.

12. We supply perfect service to make customers more satisfied and high performance-price ratio .

13. Taking an innovative approach based on scientific research, DMS Seal Manufacturer is able to develop mechanical seal pot and enhance its performance.

1. Application and properties

Suitable for reciprocating piston rod or piston single acting seal, the working pressure has a wide range of adaptability, and the pressure capacity can be enhanced by increasing the tail length size or increasing the check ring.

Small friction coefficient, The contact pressure between the mating surface and the mating surface is low, and the friction between the work face and the mating surface is the smallest in all seal types. with or without lubrication can work, wear resistance, long service life.

The working medium of the sealing sleeve has wide adaptability, and the other chemicals are not reacted except soluble alkali metal, high temperature fluorine gas and three fluoride chloride.

The working temperature range is wide, and can be used for -200 ℃ to +250 ℃.

It can be used for very high speed, very low speed, micro-stroke and other special conditions.

Suitable for aviation, military and industrial sealing groove size, The standard installation groove is the same size as the standard O ring, and the size is small. It can be designed as non standard parts to meet the sealing requirements of any size groove. The groove is open or semi open.

It can be used in rotary sealing. It can adapt to large eccentricity and beating.

2. Standard materials

Sealing sleeve: PTFE

Spring: Stainless steel 304, 316

3. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range ℃ | Speed | Medium |

3 - 1600mm | 0 - 20MPa | -200 ~ +250 | 5 m/s | High and low temperature oil and water and other fluids. |

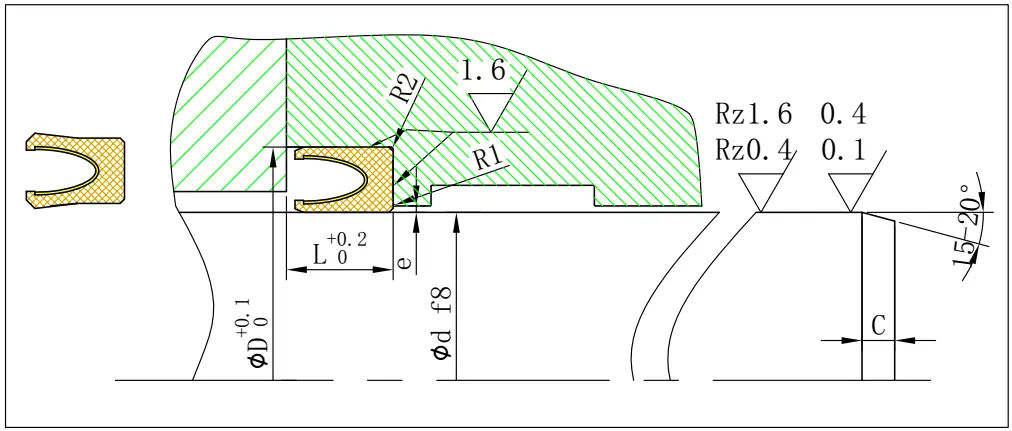

4. Installation Sizes

Back pressure surfaceR1=0.1 ~ 0.2, tank bottom R2=0.3 ~ 0.5, Import lengthC=(0.7 ~ 1.0)L.

Rod Diameter

| Groove Width | Groove Diameter | Radial Clearance

|

d | L | D | e |

2 ~ 10 | 2.5 | d+3.0 | 0.05 |

10 ~ 22 | 3.2 | d+4.0 | 0.065 |

22 ~ 52 | 4.7 | d+6.0 | 0.075 |

48 ~ 150 | 7.5 | d+10.0 | 0.09 |

150 ~ 400 | 11.0 | d+15.0 | 0.10 |

5. Matters needing attention

Ⅰ, The installation groove must be open or semi open, and it is recommended to be open.

Ⅱ, If the seal is for the rotating shaft, it is recommended that the surface hardness of the shaft should be no less than HRC40.

Ⅲ,Considering the adaptability of the working medium, the adaptability of the jacket and spring should be taken into account.

Ⅳ, It is better to install an anti fouling ring or a antifouling guide ring in the notch direction in front of the seal.

Company Features

1. Paying years of attention to the manufacture of , Dms Seals Technology Co.,limited has been considered as one of the most robust manufacturers in China. Dms Seals Technology Co.,limited is a well-established company involving the design, production, and marketing of . We are widely accepted in this industry. Dms Seals Technology Co.,limited is a domestically known company when it comes to developing and manufacturing mechanical seal pot . We have gained great success in the field. Being a reliable manufacturer and supplier, Dms Seals Technology Co.,limited boasts a wealth of experience in designing and manufacturing high-quality .

2. Quality speaks louder than number in Dms Seals Technology Co.,limited. We have the capability of researching and developing state-of-the-art technologies of mechanical seal retainer . Our advanced machine is able to fabricate such spring loaded seal with features of [拓展关键词/特点]. With the unique technology and stable quality, our garter spring seal win a wider and wider market gradually.

3. The customer service from DMS Seal Manufacturer will ensure that our customers receive the best products through our professional philosophy. Ask online! What we hold on to is: always being prepared for any eventualities. No matter from the product quality nor customer service, we will work hard to improve so as to stands firmly and stably in the market. Ask online! We are committed to preserving resources and materials as long as possible. Our goal is to stop contributing to landfills. By reusing, regenerating, and recycling products, we sustainably conserve our planet's resources. Winning more overseas market share is what we pursue now. Under the technological support, we will strive hard to win over customers by quality and service.

DMS Seal Manufacturer mechanical seal pot manufacturers for aviation

mechanical seal pot

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US