DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer Latest hydraulic pump seals suppliers manufacturers for light and medium hydraulic systems

1. Various styles of hydraulic pump seals suppliers are available for customer's selection.

2. hydraulic pump seals suppliers from Dms Seals Technology Co.,limited explores the boundary between art and design.

3. The elements of fashion, style, and personality are added to the design of DMS Seal Manufacturer hydraulic pump seals suppliers .

4. The production of DMS Seal Manufacturer is based on the industry's most sophisticated standards.

5. It comes with fine reflectivity. More light is reflected as its fabric has a high thread count and is tightly woven together.

6. The product is less vulnerable to chipping and cracking. During the production stage, it has been fired to a certain hardness level.

7. The product needs no maintenance. Using the sealed battery which charges itself automatically when there is sunlight, it requires zero maintenance.

8. Moving into the new century, DMS Seal Manufacturer remains fully committed to innovation.

9. Enhancing the customer service techniques is a focus of Dms Seals Technology Co.,limited.

10. Taking the lead in hydraulic pump seals suppliers manufacture industry, DMS Seal Manufacturer has a dominant influence in this field.

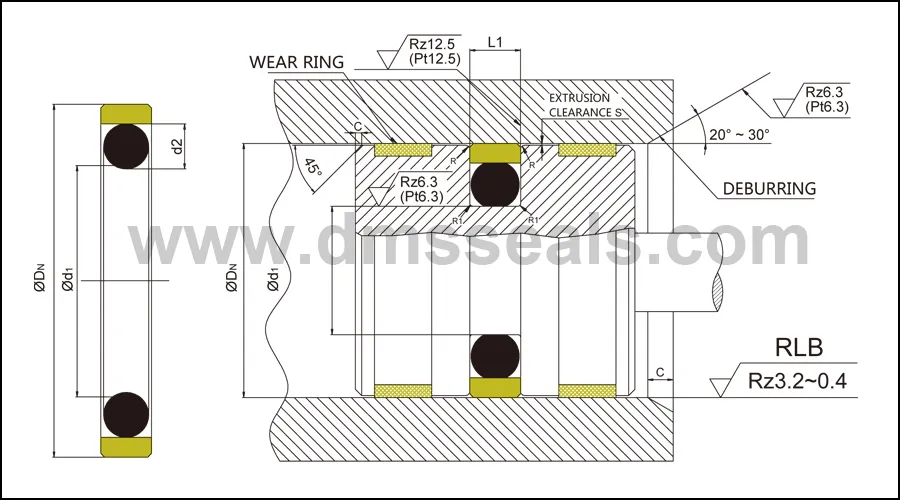

1. Installation Recommendation

2. Installation Sizes

Bore Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

8-14.9 | 15-39.9 | - | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 | |

15-39.9 | 40-79.9 | - | DN-7.5 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

40-79.9 | 80-132.9 | 15-39.9 | DN-11.0 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

80-132.9 | 133-329.9 | 40-79.9 | DN-15.5 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

133-329.9 | 330-699.9 | 80-132.9 | DN-21.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

330-669.9 | 670-99.9 | 133-329.9 | DN-24.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

670-999.9 | 330-669.9 | DN-28.0 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 | |

≥1000 | ≥1000 | ≥1000 | DN-38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

3. Application and properties

Standard double acting seal. Suitable for reciprocating motion, allowing larger extrusion clearances, has wide application. Dynamic and static sealing property are excellent, be able to work in dusty condition. Low friction, simple groove, strong adaptability to work conditions.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water and others |

6. Installation Dimensions

Bore Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

DN H9 | d1 h9 | L1+0.2 | ||

8 10 12 | 3.1 5.1 7.1 | 2.2 2.2 2.2 | GSF8*3.1*2.2 GSF10*5.1*2.2 GSF12*7.1*2.2 | 2.90*1.78 4.80*1.8 6.70*1.8 |

14 15 15 | 9.1 10.1 7.5 | 2.2 2.2 3.2 | GSF14*9.1*2.2 GSF15*10.1*2.2 GSF15*7.5*3.2 | 8.75*1.8 7.59*2.62 8.75*1.8 |

16 16 18 | 11.1 8.5 13.1 | 2.2 3.2 2.2 | GSF16*11.1*2.2 GSF16*8.5*3.2 GSF18*13.1*2.2 | 10.82*1.78 7.59*2.62 12.42*1.78 |

18 20 20 | 10.5 15.1 12.5 | 3.2 2.2 3.2 | GSF18*10.5*3.2 GSF20*15.1*2.2 GSF20*12.5*3.2 | 9.19*2.62 14.00*1.78 12.37*2.62 |

24 24 25 | 19.1 16.5 17.5 | 2.2 3.2 3.2 | GSF24*19.1*2.2 GSF24*16.5*3.2 GSF25*17.5*3.2 | 18.77*1.78 15.54*2.62 17.12*2.62 |

25 28 28 | 14 20.5 17 | 4.2 3.2 4.2 | GSF25*14*4.2 GSF28*20.5*3.2 GSF28*17*4.2 | 13.87*3.53 20.29*2.62 15.47*3.53 |

30 30 32 | 22.5 19 24.5 | 3.2 4.2 3.2 | GSF30*22.5*3.2 GSF30*19*4.2 GSF32*24.5*3.2 | 21.89*2.62 26.70*1.78 23.47*2.62 |

Company Features

1. Dms Seals Technology Co.,limited has won the respect of the industry due to the competence in the R&D and manufacture of hydraulic pump seals suppliers . Dms Seals Technology Co.,limited enjoys a good reputation in the R&D, design, production, and sales of piston seal hydraulic . We are widely accepted in the industry. Dms Seals Technology Co.,limited has been engaged in designing and manufacturing for many years. We possess in-depth expertise in this kind of product and market.

2. Dms Seals Technology Co.,limited has a strong technical force, excellent processing and manufacturing capabilities. Dms Seals Technology Co.,limited is deeply trusted by customers at home and abroad for its high quality thanks to advanced technology. Dms Seals Technology Co.,limited adopts the most advanced technology to deal with the changeable market. Dms Seals Technology Co.,limited can provide all quality certificates available for packing rod seals .

3. All DMS Seal Manufacturer staff keeps our clients in mind and does the utmost to satisfy customers. Welcome to visit our factory! Dms Seals Technology Co.,limited always keep as its service principle. Welcome to visit our factory! We are always ready to help customers for any possible problems about our hydraulic cylinder piston seals . Welcome to visit our factory!

DMS Seal Manufacturer Latest hydraulic pump seals suppliers manufacturers for light and medium hydraulic systems

hydraulic pump seals suppliers

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US