DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer hydraulic piston seals glyd ring for light and medium hydraulic systems

-

v s

- Dms Seals has professional personnel to provide consulting services in terms of product, market and logistics information.

1. DMS Seal Manufacturer hydraulic cylinder piston seals has passed various tests. For example, our QC team has tested its elasticity, color fastness and water repellency.

2. A range of machining workmanship has been adopted in the production of DMS Seal Manufacturer hydraulic cylinder piston seals . It will be fabricated under CNC forming milling process, extrusion molding, CNC engraving, machine cutting, and polishing.

3. DMS Seal Manufacturer hydraulic cylinder piston seals is developed under the concept of different principles. They are engineering mechanics, statics, dynamics, mechanics of materials, and continuum mechanics.

4. This product is resistant to tearing. The stretching process is carried out during the post-treatment of the fiber in order to improve the mechanical properties of the fiber and thereby increase the elongation at break of the fiber.

5. It features nice thermal comfort. It has the capability to allow the natural heat dissipating mechanism to work and to stay dry.

6. The product is not susceptible to the damage caused by overload and overcurrent. It is built with a heating element protection system which can effectively guard against malfunction.

7. This product is safe to use. It has passed the electrical safety test, involving electromagnetic interference level test, surge test, electrostatic discharge test, and leakage test.

8. This product is somewhat fire retardant. The insulating materials used for this product meet higher demands in glow wire testing.

9. Featuring great flexibility, it is often used in different applications for different purposes in our daily life. It is crucial for supporting and developing the economy.

10. The product is a superior quality, reliable, complete reverse osmosis drinking water purification system, which is intended for commercial applications.

11. The product is often used in remote and hard-to-reach locations where the device needs to be self-powered.

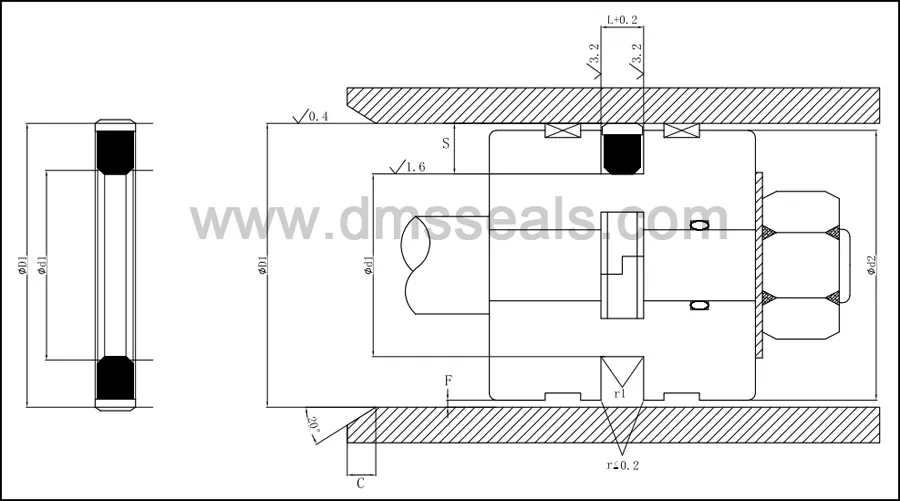

1. Installation Recommendation

2. Application and properties

Extreme wear resistance, easy installation on single-part piston without assembly aids due to the split design of the sealing ring. Assembly on one-part piston is possible. Insensitive to extreme pressure peaks. Extreme high extreme pressure resistance. High pressure an large gaps due to the special compound properties of the seal ring. Dimensions according to ISO 7425-1. Short axial assembly length. Installation in closed and undercut housings. Additional sizes of machined products available on short notice.

3. Standard materials

Sealing ring: filled modified thermoplast

O-ring: NBR

4. Working Conditions

Working Conditions | |||

Diameter Range | Pressure Range | Temperature Range | Speed |

25 - 480mm | 0 - 80MPa | -30℃ +110℃ | ≤1 m/s |

5. Installation Dimensions

D1 | d1 | L | |

25 32 40 | 16 21 26.3 | 4.2 4.2 5.8 | OK25*16*4.2 OK32*21*4.2 OK40*26.3*5.8 |

40 50 50 | 29 34.5 36.3 | 4.2 6.3 5.8 | OK40*29*4.2 OK50*34.5*6.3 OK50*36.3*5.8 |

50 50 55 | 37 39 44 | 8 4.2 4.2 | OK50*37*8 OK50*39*4.2 OK55*44*4.2 |

55 60 60 | 44 41.7 49 | 4.2 7 4.2 | OK55*44*4.2 OK60*41.7*7 OK60*49*4.2 |

63 63 63 | 44.7 47.5 52 | 7 6.3 4.2 | OK63*44.7*7 OK63*47.5*6.3 OK63*52*4.2 |

70 70 70 | 51.7 54.5 54.5 | 7 6.3 6.3 | OK70*51.7*7 OK70*54.5*6.3 OK70*54.5*6.3 |

70 75 75 | 59 54 59.5 | 4.2 8 6.3 | OK70*59*4.2 OK75*54*8 OK75*59.5*6.3 |

80 80 85 | 59 64.5 64 | 8 6.3 8 | OK80*59*8 OK80*64.5*6.3 OK85*64*8 |

90 90 95 | 69 74.5 74 | 8 6.3 8 | OK90*69*8 OK90*74.5*6.3 OK95*74*8 |

100 100 105 | 79 84.5 84 | 8 6.3 8 | OK100*79*8 OK100*84.5*6.3 OK105*84*8 |

110 110 115 | 89 94.5 94 | 8 6.3 8 | OK110*89*8 OK110*94.5*6.3 OK115*94*8 |

115 120 125 | 100 99 104 | 8 8 8 | OK115*100*8 OK120*99*8 OK125*104*8 |

125 130 130 | 109.5 109 114.5 | 6.3 8 6.3 | OK125*109.5*6.3 OK130*109*8 OK130*114.5*6.3 |

130 135 135 | 115 114 119.5 | 8 8 6.3 | OK130*115*8 OK135*114*8 OK135*119.5*6.3 |

140 140 145 | 119 125 124 | 8 8 8 | OK140*119*8 OK140*125*8 OK145*124*8 |

150 150 152.4 | 129 135 131.5 | 8 8 8 | OK150*129*8 OK150*135*8 OK152.4*131.5*8 |

160 160 165 | 139 148 144 | 8 8 8 | OK160*139*8 OK160*148*8 OK165*144*8 |

170 175 180 | 149 154 159 | 8 8 8 | OK170*149*8 OK175*154*8 OK180*159*8 |

190 200 210 | 169 179 189 | 8 8 8 | OK190*169*8 OK200*179*8 OK210*189*8 |

220 220 230 | 199 205 209 | 8 8 8 | OK220*199*8 OK220*205*8 OK230*209*8 |

240 250 260 | 225 229 239 | 8 8 8 | OK240*225*8 OK250*229*8 OK260*239*8 |

270 280 290 | 249 255.5 271 | 8 8 9.5 | OK270*249*8 OK280*255.5*8 OK290*271*9.5 |

300 320 330 | 272 292 302 | 9.5 9.5 9.5 | OK300*272*9.5 OK320*292*9.5 OK330*302*9.5 |

350 370 420 | 322 342 392 | 9.5 9.5 9.5 | OK350*322*9.5 OK370*342*9.5 OK420*392*9.5 |

450 480 | 422 452 | 9.5 9.5 | OK450*422*9.5 OK480*452*9.5 |

Company Features

1. Dms Seals Technology Co.,limited gets a number of branch offices located in overseas countries. As a major research and development enterprise of China’s hydraulic piston seals , Dms Seals Technology Co.,limited occupies a leading position in the industry. As a new piston seals production base, Dms Seals Technology Co.,limited is rising. Dms Seals Technology Co.,limited is one of the largest enterprise for manufacturing and exporting o-ring seal.

2. We have expanded our business across the world. After years of exploration, we distribute our products to our customers around the world with the help of our sales network. We house a series of manufacturing facilities, including engineering, manufacturing, and testing machines. These machines guarantee an efficient and time-saving method of manufacturing to meet customer requirement in short lead-time. We have built a high-performing team. We have invested in developing leadership abilities and management ability to bring their superiority into full play. This also enables them to better serve clients. Our factory has the most efficient manufacturing machines. They can serve to streamline the production process, improve production efficiency, and produce better quality products. Our company attracts and retains top talents. As skilled problem-solvers for us and our customers, these people have all the skills, knowledge and competency of specialist trades to develop extraordinary products.

3. We bear social responsibilities. This is why we attach great importance to the energy and resource efficiency of our products and ensure that we comply with all recognized environmental and social standards. We responsibly and sustainably manage our products. We aim to reduce resource use, degradation, and pollution along the whole life cycle of our products. We will gradually gear towards a more sustainable manufacturing approach. We will not generate wastes or pollution that impose a burden on the environment. We help clients with all aspects with product R&D– from concept and design to engineering and testing, to strategic sourcing and freight forwarding. Get price! As a socially responsible business, we continuously improve and track environmental performance, and improve the understanding and guidance of the environment for all employees.

DMS Seal Manufacturer hydraulic piston seals glyd ring for light and medium hydraulic systems

hydraulic piston seals

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US