DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer hydraulic piston seal installation with nbr or fkm o ring for pneumatic equipment

1. DMS Seal Manufacturer is manufactured utilizing the strong technical strength, advanced equipment.

2. DMS Seal Manufacturer adopts premium raw materials that can be a total guaranteed of quality.

3. The production process of DMS Seal Manufacturer hydraulic piston seal installation adheres to the requirement of standardization production.

4. DMS Seal Manufacturer is fabricated with the aid of highly advanced machines.

5. This product is built to last. It has a sturdy frame that is able to endure daily heavy use or even abuse without frame deformation.

6. This product is safe. The dyes used are dispersed-free, phenylenediamine-free, and Okemo Tex certified, which proves that it poses no harmful risks.

7. This product has a high dimension precision. It is processed by a straight line edge sealing machine which finishes the edge sealing, cutting, deburring and chamfering with high accuracy.

8. This product features the desired bonding. It has tested by a tensile test machine for the peel strength of adhesive bonds between constructions.

9. This product matches with the latest development of the industry and meets the demands of customers.

10. The product is extensively demanded in the market due to its unsurpassable advantages.

11. The product will have a larger market share with the development of the market.

12. This product brings economic benefits to customers with bright industry prospects.

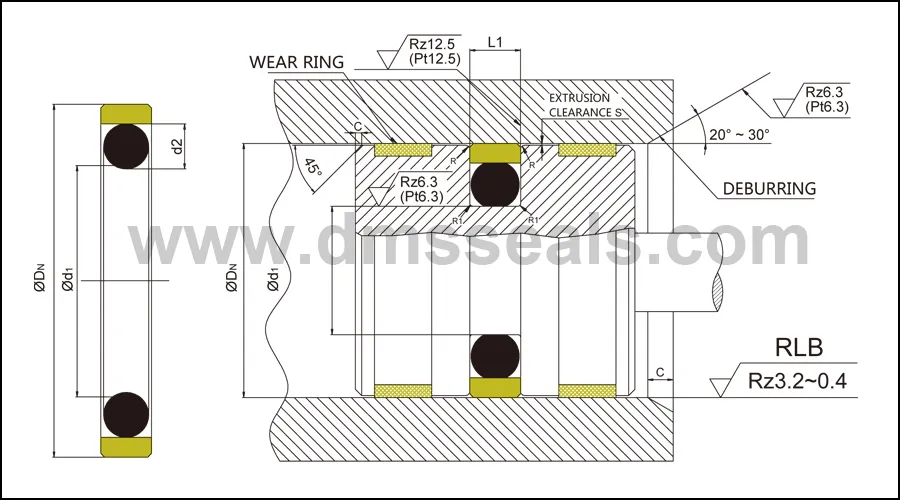

1. Installation Recommendation

2. Installation Sizes

Bore Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

8-14.9 | 15-39.9 | - | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 | |

15-39.9 | 40-79.9 | - | DN-7.5 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

40-79.9 | 80-132.9 | 15-39.9 | DN-11.0 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

80-132.9 | 133-329.9 | 40-79.9 | DN-15.5 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

133-329.9 | 330-699.9 | 80-132.9 | DN-21.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

330-669.9 | 670-99.9 | 133-329.9 | DN-24.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

670-999.9 | 330-669.9 | DN-28.0 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 | |

≥1000 | ≥1000 | ≥1000 | DN-38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

3. Application and properties

Standard double acting seal. Suitable for reciprocating motion, allowing larger extrusion clearances, has wide application. Dynamic and static sealing property are excellent, be able to work in dusty condition. Low friction, simple groove, strong adaptability to work conditions.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water and others |

6. Installation Dimensions

Bore Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

DN H9 | d1 h9 | L1+0.2 | ||

8 10 12 | 3.1 5.1 7.1 | 2.2 2.2 2.2 | GSF8*3.1*2.2 GSF10*5.1*2.2 GSF12*7.1*2.2 | 2.90*1.78 4.80*1.8 6.70*1.8 |

14 15 15 | 9.1 10.1 7.5 | 2.2 2.2 3.2 | GSF14*9.1*2.2 GSF15*10.1*2.2 GSF15*7.5*3.2 | 8.75*1.8 7.59*2.62 8.75*1.8 |

16 16 18 | 11.1 8.5 13.1 | 2.2 3.2 2.2 | GSF16*11.1*2.2 GSF16*8.5*3.2 GSF18*13.1*2.2 | 10.82*1.78 7.59*2.62 12.42*1.78 |

18 20 20 | 10.5 15.1 12.5 | 3.2 2.2 3.2 | GSF18*10.5*3.2 GSF20*15.1*2.2 GSF20*12.5*3.2 | 9.19*2.62 14.00*1.78 12.37*2.62 |

24 24 25 | 19.1 16.5 17.5 | 2.2 3.2 3.2 | GSF24*19.1*2.2 GSF24*16.5*3.2 GSF25*17.5*3.2 | 18.77*1.78 15.54*2.62 17.12*2.62 |

25 28 28 | 14 20.5 17 | 4.2 3.2 4.2 | GSF25*14*4.2 GSF28*20.5*3.2 GSF28*17*4.2 | 13.87*3.53 20.29*2.62 15.47*3.53 |

30 30 32 | 22.5 19 24.5 | 3.2 4.2 3.2 | GSF30*22.5*3.2 GSF30*19*4.2 GSF32*24.5*3.2 | 21.89*2.62 26.70*1.78 23.47*2.62 |

Company Features

1. Dms Seals Technology Co.,limited is a large manufacturer for hydraulic piston seal installation . Dms Seals Technology Co.,limited is an export-oriented private enterprise mainly engaged in the production of kit seal cylinder . Dms Seals Technology Co.,limited is well established in buy hydraulic seals industry. Dms Seals Technology Co.,limited is internationally outstanding in the field of hydraulic seals companies .

2. We introduced advanced rubber piston rings equipment, which produce high quality products with sophisticated design and fine finish. In order to meet the increasingly diversified needs of global consumers, Dms Seals Technology Co.,limited has established a global R&D center. As is known to all us that DMS Seal Manufacturer has made a great achievement since the launch of double acting piston cup . Expect the work of our professional staff, the advanced machine also contributes to the quality assurance of hydraulic cylinder packing material . The core competitiveness for Dms Seals Technology Co.,limited lies in its technology.

3. We are always active in driving our social responsibility programs. We will always mobilise our employees in different departments to work together to find solutions that can help create a bigger positive impact. We are trying to seek and use clean energy resources to support our production. In the next phase, we will seek a more sustainable packaging way. Our business philosophy is that we strive to create products of superior quality and value while building a more sustainable future. Adhering to the highest ethical standards, we operate our business and treat all of our co-workers, customers, and suppliers with honesty, integrity, and respect. Our mission is to understand our customers as well as our market to provide products and services beyond their expectations to enhance their quality of life.

DMS Seal Manufacturer hydraulic piston seal installation with nbr or fkm o ring for pneumatic equipment

hydraulic piston seal installation

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US